High-temperature high-pressure ultralow sulfur-and-phosphorus valve body casting forming process

A high temperature and high pressure, casting molding technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems that the quality of casting products cannot meet the requirements, high temperature molten steel is easy to stick to sand, and it is easy to produce shrinkage cavities. Avoid cold insulation defects, reduce shrinkage cavities, and avoid the effect of flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

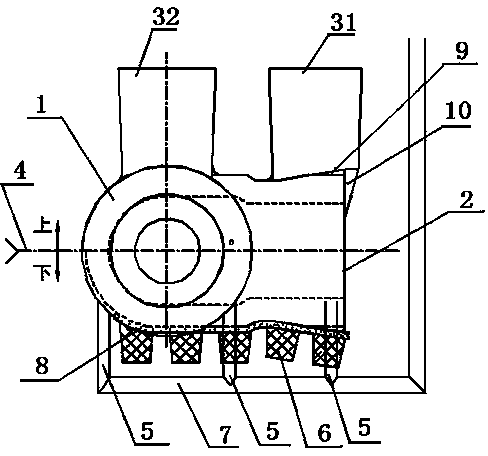

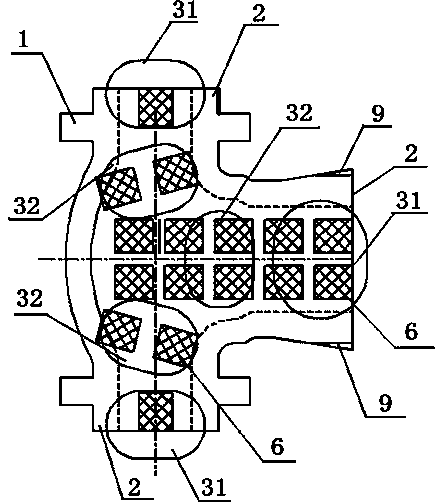

[0022] The technical solutions and beneficial effects of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 An ultra-low sulfur phosphorus high temperature and high pressure valve body casting molding process is shown. The ultra low sulfur phosphorus high temperature and high pressure valve body casting 1 has three nozzles 2. The valve body casting mold is manually operated with resin sand. The casting molding process In the bottom return pouring system, the plane where the centers of the three nozzles 2 are located is the parting surface 4, and the casting is divided into upper and lower halves; the first riser 31 is respectively arranged directly above the three nozzles 2, and the second A riser 31 extends down the pipe mouth to set an inclined riser feeding channel 10, and a second riser 32 is respectively provided above the intersection of each pipe of the valve body casting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com