Puer tea leaching powder particles and preparation method and application thereof

A Pu-erh tea extraction technology, applied in the field of tobacco processing, can solve the problems of insufficient release of active ingredients, unknown chemical components of smoke, green tea leaves, etc., to achieve rich content, sensory quality and smoking comfort The effect of improving, tea fragrance and cigarette fragrance coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

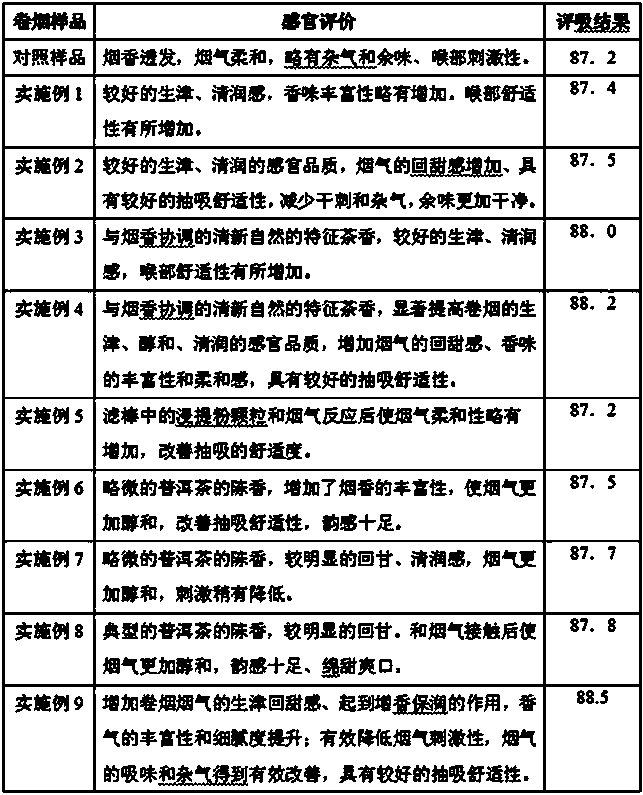

Examples

Embodiment 1

[0031] (1) Extract raw Puer tea according to the conventional extraction method to obtain Puer tea extract, and then sieve it to 120 mesh after conventional centrifugal spray drying to obtain Puer tea extract powder;

[0032] (2) Prepare materials according to the following mass percentages:

[0033] Pu-erh tea extract powder 99.5%,

[0034] Carboxymethylcellulose 0.5%,

[0035] The sum of each component is 100%;

[0036] (3) Dissolve the carboxymethyl cellulose prepared in step (2) in water first to make a binder solution with a concentration of 3w / v%, atomize it and spray it on the Pu-erh tea extract powder for bonding into granules, sieve After separation, 20-60 mesh Pu'er tea extraction powder granules are obtained.

[0037] The application of the obtained Pu’er tea extract powder granules is used in the following manner: in the filter rod forming process, the Pu’er tea extract powder granules are evenly dispersed in the filter rod tow in an amount of 1 mg / mm to directl...

Embodiment 2

[0039] (1) Extract raw Pu-erh tea according to conventional extraction methods to obtain Pu-erh tea extract, and then sieve to 150 mesh after conventional centrifugal spray drying to obtain Pu-erh tea extract powder;

[0040] (2) Prepare materials according to the following mass percentages:

[0041] Pu-erh tea extract powder 97%,

[0042] Pectin 1%

[0043] Gum Arabic 2%,

[0044] The sum of each component is 100%;

[0045] (3) Dissolve the hydrophilic polymer binder prepared in step (2) in water first to make a binder solution with a concentration of 2w / v%, atomize it and spray it on the Pu-erh tea extract powder for bonding into granules , after sieving, 10-50 meshes of Pu-erh tea extract powder granules are obtained.

[0046] The application of the obtained Pu’er tea extract powder particles is used in the following manner: in the filter rod forming process, the Pu’er tea extract powder particles are evenly dispersed in the filter rod tow in an amount of 3mg / mm to make...

Embodiment 3

[0048] (1) Extract raw Puer tea according to the conventional extraction method to obtain Puer tea extract, and then sieve it to more than 100 mesh after conventional freeze-drying to obtain Puer tea extract powder;

[0049] (2) Prepare materials according to the following mass percentages:

[0050] Pu-erh tea extract powder 98%,

[0051] Edible gelatin 2%,

[0052] The sum of each component is 100%;

[0053] (3) Dissolve the hydrophilic polymer binder prepared in step (2) in water first to make a binder solution with a concentration of 1w / v%, atomize it and spray it on the Pu-erh tea extract powder for bonding into granules , after sieving, 20-60 meshes of Pu-erh tea extract powder granules are obtained.

[0054] The application of the obtained Pu’er tea extract powder granules is used in the following manner: in the filter rod forming process, the Pu’er tea extract powder granules are evenly dispersed in the filter rod tow in an amount of 1 mg / mm to make a functional type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com