Soft portable nutritious rice bread and production method thereof

A technology of rice bread and rice flour, applied in the field of soft convenient and nutritious rice bread, which can solve the problems of prolonging the storage time of rice bread, hindering water migration and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

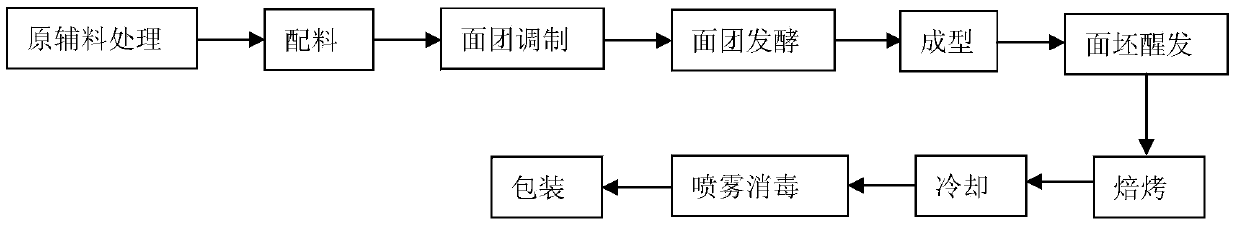

Method used

Image

Examples

Embodiment example 1

[0130] Implementation Case 1: Example of Basic Preparation of Rice Bread

[0131] (1) The making of rice flour material:

[0132] Rice (provided by Huanggang Dongpo Grain and Oil Group, Hubei) was washed with running water, soaked at room temperature for 12 hours, refined, sieved the rice slurry, dehydrated and dried to make the water content to 13.5%, crushed, passed through a 100-mesh standard sieve, and obtained rice flour, spare;

[0133] (2) Preparation of cooked powder:

[0134] 1) Take the rice flour material or commercially available potato flour prepared in step (1), and steam it with steam at 100° C. for 30 minutes, so that the degree of gelatinization of the original flour reaches 80%, to obtain gelatinized powder;

[0135] 2) Dried the gelatinized powder, made the water content to 13.2%, pulverized, passed through a 100-mesh standard sieve to obtain cooked powder, and set aside;

[0136] (3) Production of germinated rice flour:

[0137] 1) Wash the rice, disinf...

Embodiment 2

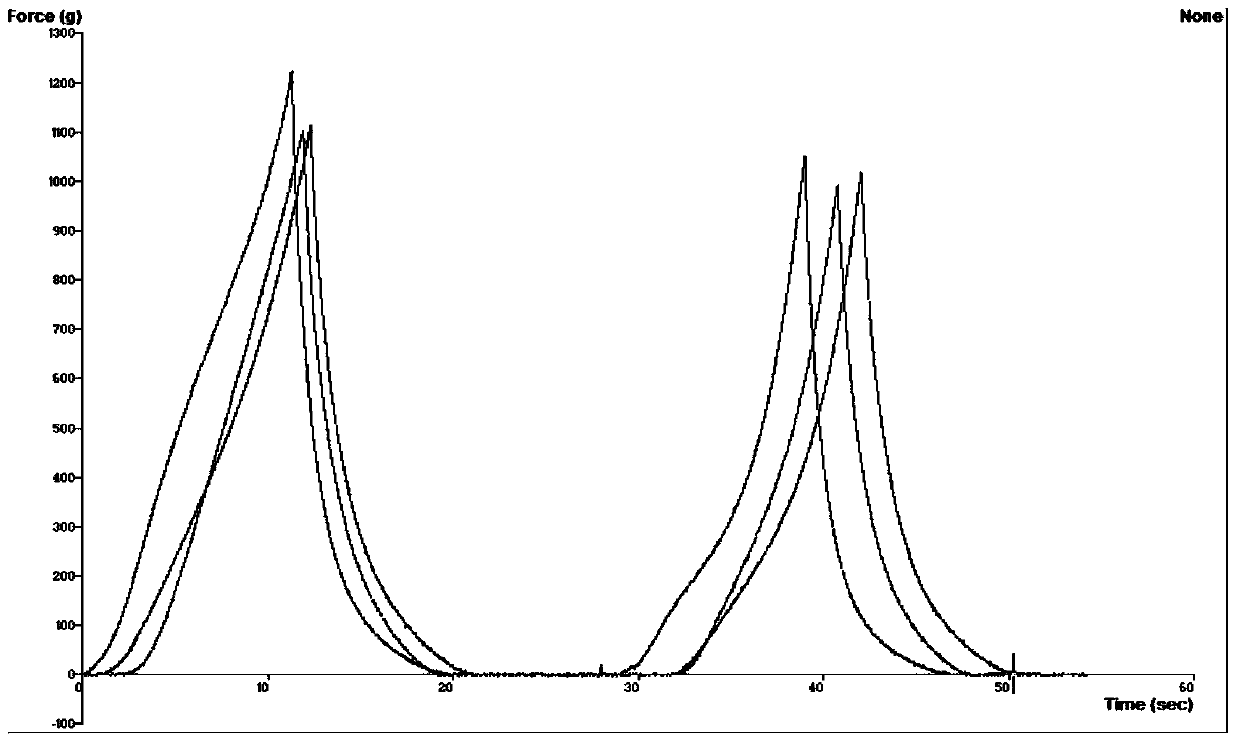

[0159] Embodiment 2: the impact of cooked powder material of different degrees of gelatinization on the storage crystallinity and hardness of rice bread

[0160] Refer to Example 1 for the preparation methods of rice flour, cooked flour and germinated rice flour in this example.

[0161] (1) Weigh each raw and auxiliary material according to the following dosage: 500g of rice flour, 20g of cooked powder, 65g of gluten powder, 125g of white sugar, 50g of butter, 40g of egg, and Brett yeast ZSM-0017g;

[0162] (2) Pass the rice flour and cooked rice flour through a 100-mesh standard sieve, melt the butter into a liquid state at 35°C, beat the eggs into egg liquid, add 3g of white sugar and 10g of warm Boiling water, activated for 10 minutes, to obtain Brettanomyces castel activation solution, set aside;

[0163] (3) Mix the above-mentioned raw and auxiliary materials with flour, add 300g of warm water in total, and knead the dough until the surface of the dough is smooth and no...

Embodiment 3

[0173] Embodiment 3: the application example of different starter

[0174] Refer to Example 1 for the preparation methods of rice flour, cooked flour and germinated rice flour in this example.

[0175] (1) Take each raw and auxiliary material according to the following dosage: rice flour material 500g, cooked potato flour 25g in the cooked powder material, gluten powder 75g, white granulated sugar 125g, butter 50g, egg 45g, Angel active dry yeast (Hubei Yichang, Product of Angel Yeast Co., Ltd.) 7.5g or Brettanomyces custersii ZSM-001 inoculum (patent number: ZL2007100536112) 7.5g or Brettanomyces custersii ZSM-001 inoculum 4.5g + vegetable milk Lactobacillus plantarum ZSM-002 bacterial agent (patent number: ZL2009100638581) 3g;

[0176] (2) Pass the rice flour and cooked potato flour through a 100-mesh standard sieve, melt the butter into a liquid state at 35°C, beat the eggs into egg liquid, add 3g of white sugar and 15g of warm water to the starter in step (1) before use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com