Water boiler with double preheating modes

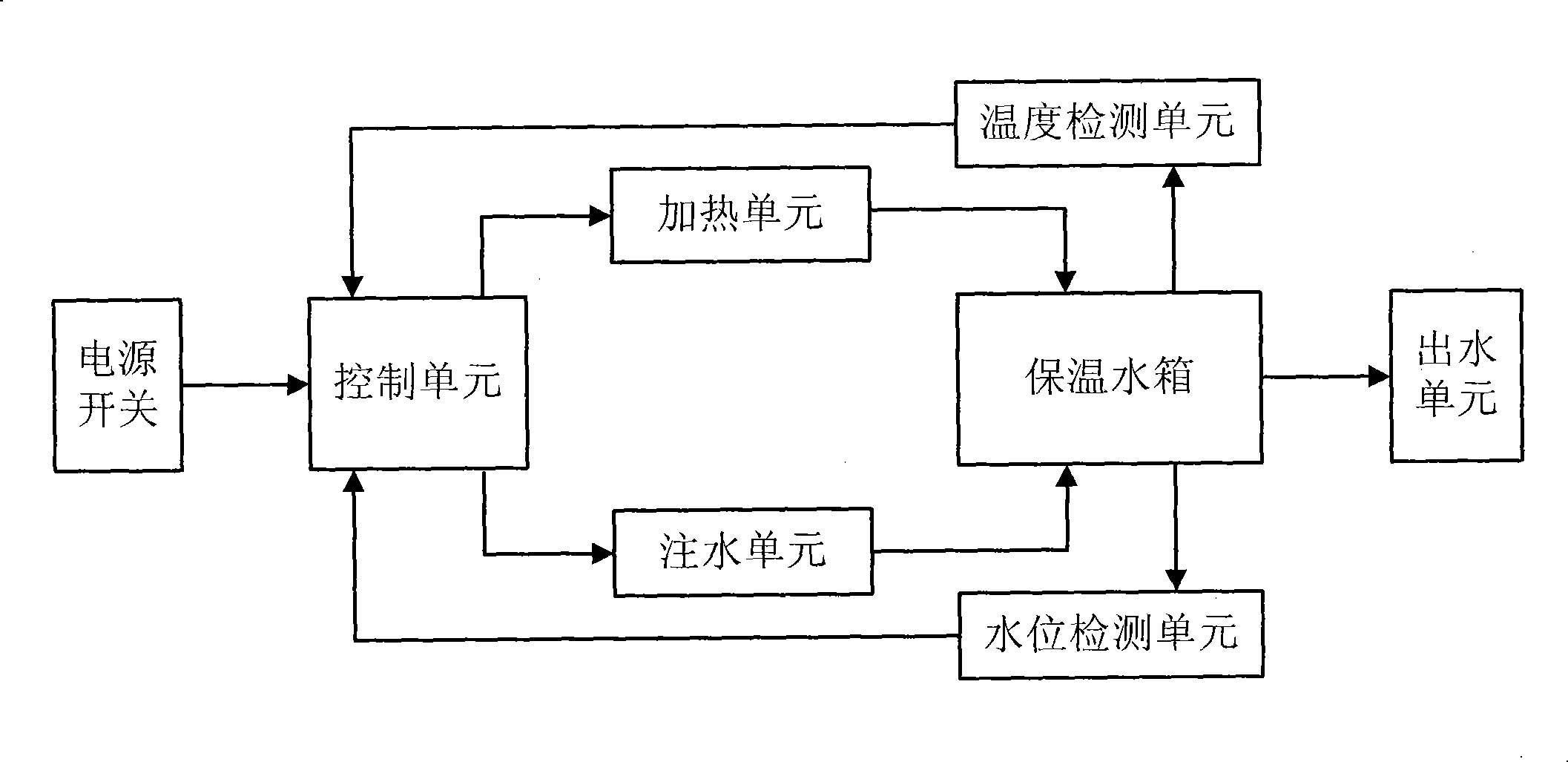

A water boiler and preheating water tank technology, applied in water heaters, fluid heaters, chemical instruments and methods, etc., can solve the problems of increasing the volume of the boiling water tank, long heating time, slow heating efficiency, etc., and improve heating efficiency. , The effect of ensuring healthy drinking water and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

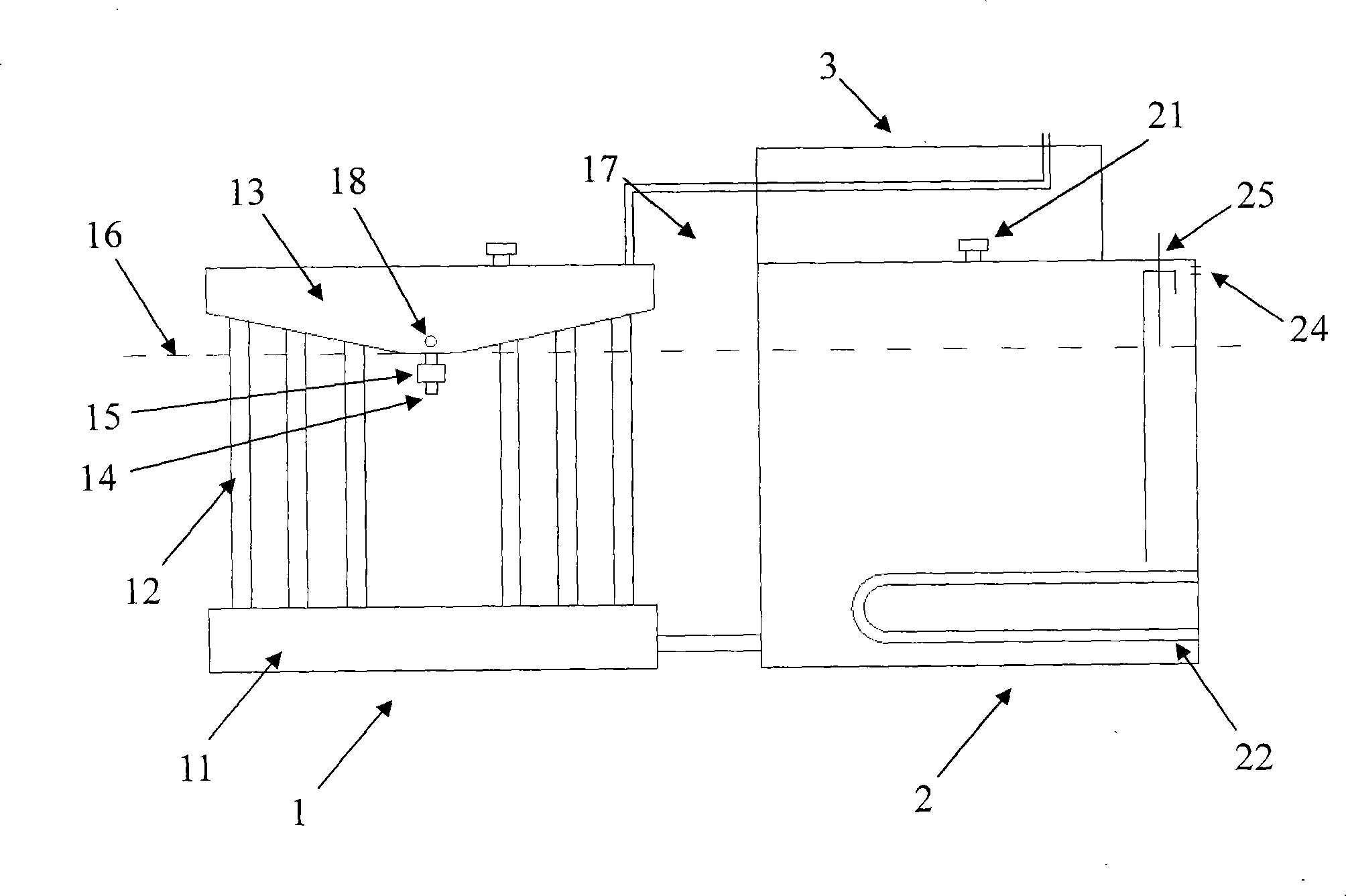

[0033] The structure of a double preheating water boiler of the present invention is as follows: figure 2 As shown, the water boiler includes a boiling water tank 1, a preheating water tank 2 and a cold water tank 3;

[0034] The cold water tank 3 is arranged above the preheated water tank 2, and is used to replenish water to the preheated water tank 2;

[0035] The preheated water tank 2 is used to heat the cold water contained in it to a preset temperature; the bottom of the preheated water tank 2 is provided with a preheating heating pipe 22, and the connection between the top and the cold water tank 3 is provided with a cold water Water inlet electromagnetic valve 21, the top of side wall is provided with overflow port 24; Water level detection probe 25 stretches into the inside of described preheating water tank 2, is used for detecting the water level of the water in described preheating water tank 2, and described boiling water The device controls the replenishment of...

Embodiment 2

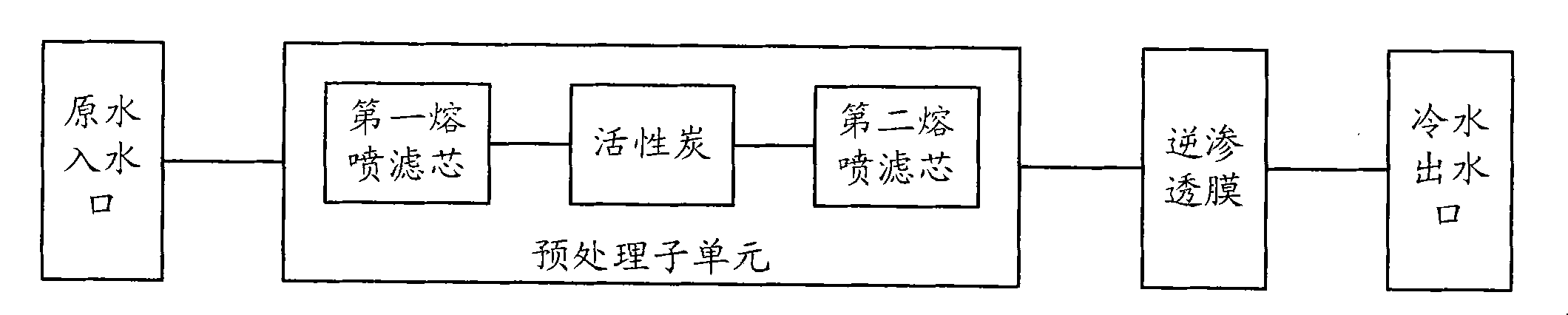

[0049] This embodiment is similar to Embodiment 1, except that the water boiler also includes a purification unit for filtering impurities in the raw water and softening the water quality; the structure of the purification unit is as follows image 3 As shown, it includes a raw water inlet, a pretreatment subunit, a reverse osmosis membrane and a cold water outlet; the pretreatment subunit is connected to the raw water inlet, and is used to filter impurities and suspended impurities in the raw water injected from the raw water inlet. matter; including the first melt-blown filter element, activated carbon and the second melt-blown filter element, the raw water enters the reverse osmosis membrane after passing through the first melt-blown filter element, activated carbon and the second melt-blown filter element; the filtration accuracy of the first melt-blown filter element is 5 microns, the filtration accuracy of the second melt-blown filter element is 1 micron. The reverse osm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com