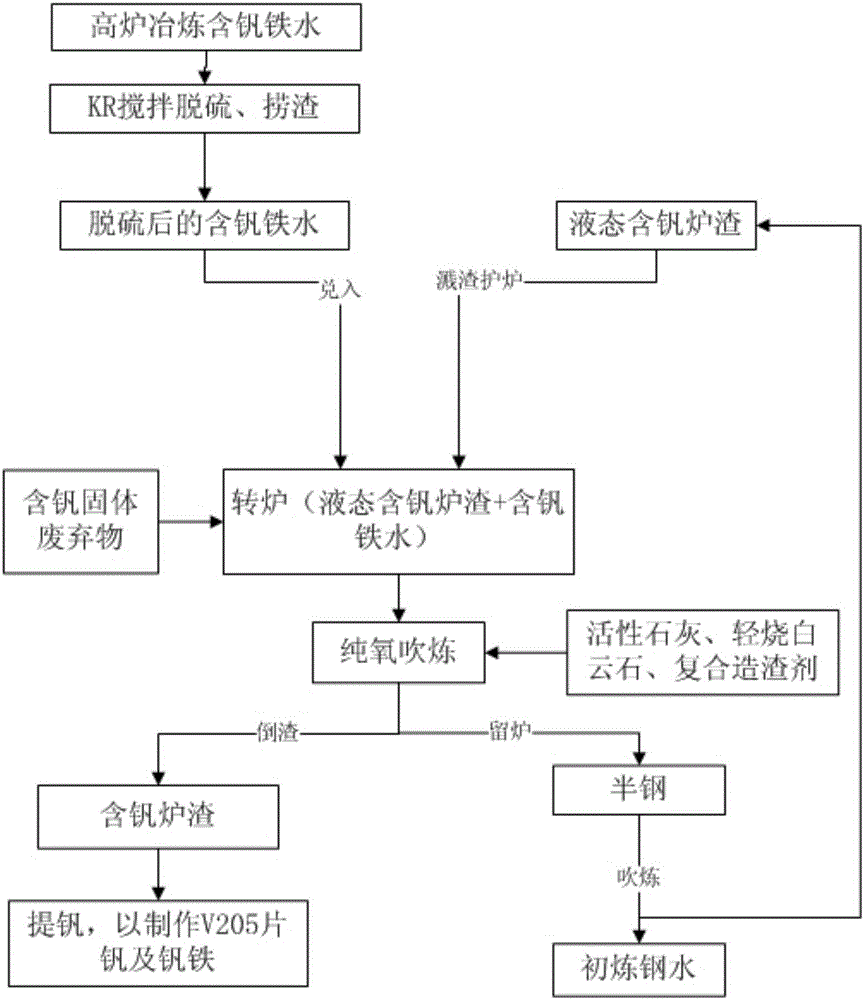

A kind of method of converter single combination extracting vanadium to make steel

A single vanadium extraction and converter technology, applied in the manufacture of converters, etc., can solve the problems of low comprehensive utilization rate, potential safety hazards in the recovery process, low recovery efficiency of vanadium resources, etc., and achieve high slag removal rate and control of slag dumping time Precise, high-angle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method of the invention is used to produce the anti-corrosion pipeline steel with products C≤0.12%, P≤0.015% and S≤0.008%. This steel product has strict requirements on desulfurization process, and the steps are as follows:

[0038] 1) Smelting vanadium titanomagnetite in a blast furnace to obtain vanadium-containing molten iron with C content of 4.35%, Si content of 0.13%, Mn content of 0.22%, P content of 0.093%, S content of 0.075%, and V content of 0.32% .

[0039] 2) Desulfurizing the vanadium-containing molten iron obtained in step 1) to 0.004% (by mass) after KR stirring and desulfurization; removing the desulfurization slag in the vanadium-containing molten iron, the slag removal rate was 99%, and the obtained slag-removing slag contained 99%. The vanadium molten iron will be mixed into the converter to extract vanadium to make steel, and the converter needs to be protected by slag splashing in advance.

[0040] 3) 83t of vanadium-containing molten iron aft...

Embodiment 2

[0047] The method of the present invention is used to produce the hot-rolled ribbed steel bar for reinforced concrete with products C≤0.25%, P≤0.045%, S≤0.045%, and the steps are as follows:

[0048] 1) Smelting vanadium titanomagnetite in a blast furnace to obtain vanadium-containing molten iron with C content of 4.40%, Si content of 0.15%, Mn content of 0.19%, P content of 0.095%, S content of 0.073%, and V content of 0.33% .

[0049] 2) Desulfurizing the vanadium-containing molten iron obtained in step 1) to 0.058% (by mass) after KR stirring and desulfurization; taking out the desulfurization slag in the vanadium-containing molten iron, the slag rate was 97%, and the obtained slag-removing slag contained 97%. The vanadium molten iron will be mixed into the converter to extract vanadium to make steel, and the converter needs to be protected by slag splashing in advance.

[0050] 3) 80t of vanadium-containing molten iron after desulfurization was added to the converter that...

Embodiment 3

[0057] Using the method of the invention to produce hard wire steel with products C≥0.58%, P≤0.030%, S≤0.030%, the steps are as follows:

[0058] 1) Smelting vanadium titanomagnetite in blast furnace to obtain vanadium-containing molten iron with C content of 4.29%, Si content of 0.18%, Mn content of 0.16%, P content of 0.085%, S content of 0.095%, and V content of 0.26% .

[0059] 2) Desulfurizing the vanadium-containing molten iron obtained in step 1) to 0.035% (by mass) after KR stirring and desulfurization; taking out the desulfurization slag in the vanadium-containing molten iron, the slag rate was 98%, and the obtained slag-removing slag contained The vanadium molten iron will be mixed into the converter to extract vanadium to make steel, and the converter needs to be protected by slag splashing in advance.

[0060] 3) adding 83t (tons) of vanadium-containing molten iron after desulfurization into the converter that leaves 1t of liquid vanadium-containing slag, adding 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com