A kind of coal catalytic gasification method

A coal catalytic gasification and catalyst technology, applied in the direction of granular/powdered fuel gasification, etc., can solve problems that affect normal production, narrow optional range, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

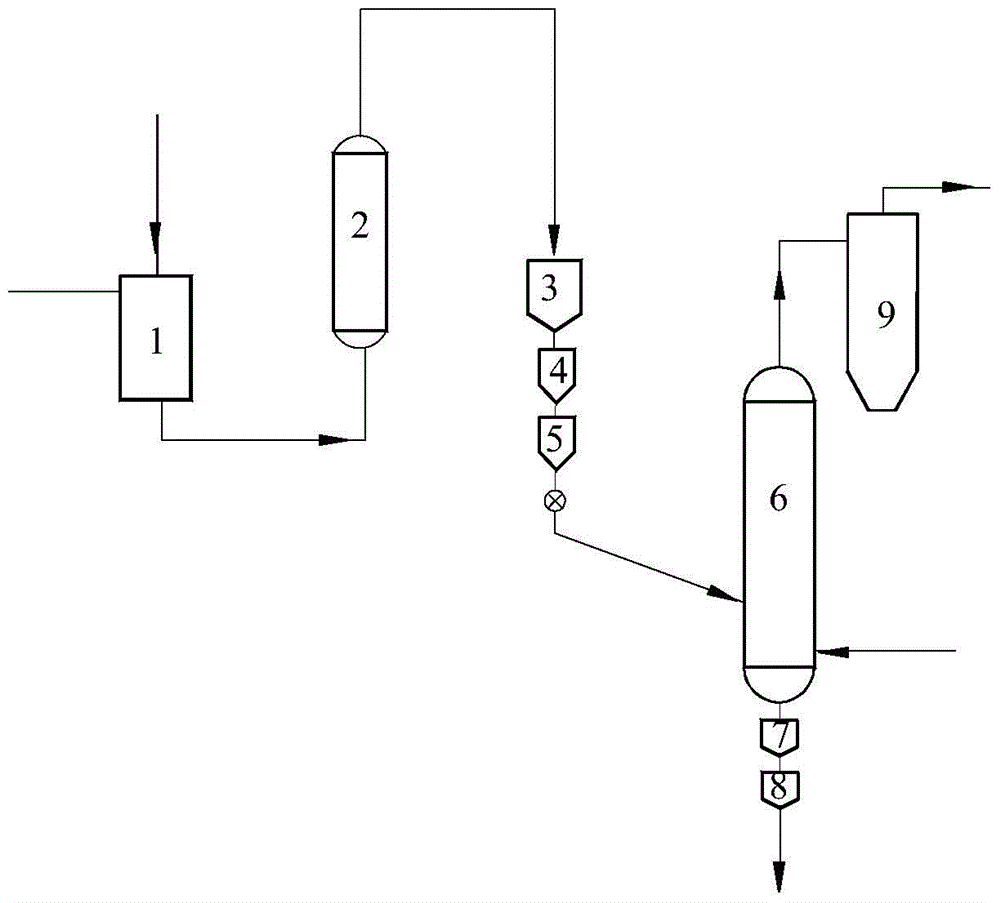

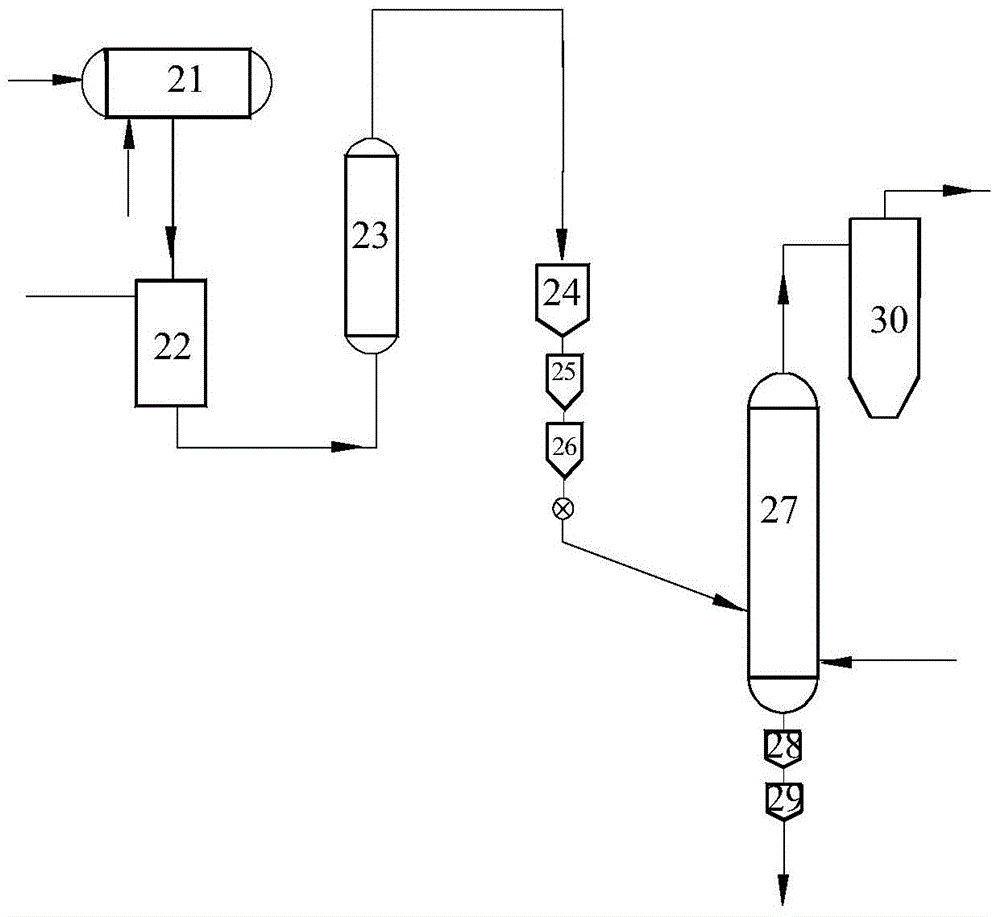

Method used

Image

Examples

Embodiment 1

[0056] Select coal type 1 to investigate whether it is suitable for catalytic gasification process:

[0057] Coal sampling is carried out according to GB475, which will be pulverized and sieved to obtain 80-160 mesh coal; then a certain amount of potassium carbonate catalyst aqueous solution is added for catalyst loading, and the amount of catalyst added is 10% of the coal mass, and the raw materials are dried to obtain The gasified feedstock is labeled Feedstock 1.

[0058] Conduct cohesive inspection of raw material 1: Put raw material 1 into the crucible, open the atmosphere muffle furnace, set the reaction temperature to 700°C, pass water vapor into the furnace to replace the air in the furnace for a period of time after stabilization, and then open the furnace door to Put the sample loading crucible into the furnace, increase the steam flow rate to quickly raise the furnace pressure to 3.5MPa, place it at 3.5MPa and 700°C for 7min, then take out the crucible and place it ...

Embodiment 2

[0064] Select coal type 2 to investigate whether it is suitable for catalytic gasification process:

[0065] Coal sampling is carried out according to GB475, which will be pulverized and sieved to obtain 80-160 mesh coal; then a certain amount of potassium carbonate catalyst aqueous solution is added for catalyst loading, and the amount of catalyst added is 10% of the coal mass, and the raw materials are dried to obtain The gasified feedstock is labeled Feedstock 2.

[0066] Carry out cohesive inspection of raw material 2: Put raw material 2 into the crucible, open the atmosphere muffle furnace, set the reaction temperature to 700°C, pass water vapor into the furnace to replace the air in the furnace for a period of time after stabilization, and then open the furnace door to Put the sample loading crucible into the furnace, increase the steam flow rate to quickly raise the furnace pressure to 3.5MPa, place it at 3.5MPa and 700°C for 7min, then take out the crucible and place i...

Embodiment 3

[0073] The coal type 3 to be used in the catalytic gasification process will be sampled according to GB475, and will be pulverized and sieved to obtain 80-160 mesh coal, which will be marked as raw material 1; after that, a certain amount of potassium carbonate catalyst aqueous solution is added to carry out catalyst loading. The addition amount is 10% of the coal mass, and the raw material for preparation is dried to obtain the gasification raw material, which is marked as raw material 2.

[0074] Carry out cohesive inspection of raw material 2: Put raw material 2 into the crucible, open the atmosphere muffle furnace, set the reaction temperature to 700°C, pass water vapor into the furnace to replace the air in the furnace for a period of time after stabilization, and then open the furnace door to Put the sample loading crucible into the furnace, increase the steam flow rate to quickly raise the furnace pressure to 3.5MPa, place it at 3.5MPa and 700°C for 7min, then take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com