A kind of early-strength composite foam concrete foaming agent and preparation method thereof

A composite foam and composite foaming technology, applied in the field of building materials, can solve problems such as short shelf life, large foam diameter, and complicated preparation process, and achieve the effects of rapid early strength improvement, excellent foam stability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

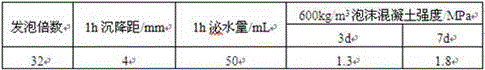

Embodiment 1

[0023] An early-strength composite foam concrete foaming agent is composed of a composite foam component, a foam-stabilizing component, an early-strength component and water, and the distribution ratio of each component is calculated by mass percentage: composite foam component: 12 Sodium Alkyl Sulfate 15.0%, Sodium Cetyl Sulfonate 15.8%, Tea Saponin 9.2%; Foam Stabilizing Component: Lauryl Alcohol 4.0%, Cellulose Ether 1.0%; Early Strength Component: Triethanolamine 2.0%, Sodium sulfate 8.0%; water 45.0%.

[0024] A method for preparing an early-strength type composite foam concrete foaming agent, comprising the following steps: ①The container is placed in a constant temperature water bath at 100°C; ②The composite foaming component, the early-strength component and water are placed in the container; ③ Stir slowly at 60rpm for 1-5min to make it evenly mixed; ④ Add foam stabilizing components and continue stirring for 1-5min; ⑤ Cool to room temperature to obtain early-strength ...

Embodiment 2

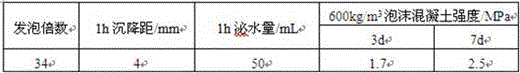

[0029] An early-strength composite foam concrete foaming agent is composed of a composite foam component, a foam-stabilizing component, an early-strength component and water, and the distribution ratio of each component is calculated by mass percentage: composite foam component: 12 Sodium Alkyl Sulfate 20.0%, Cocamidopropyl Betaine 40.0%, Tea Saponin 10.0%, Saponin 7.0%; Foam Stabilizing Components: Lauryl Alcohol 4.0%, Cellulose Ether 1.0%; Early Strength Components : Triethanolamine 0.5%, sodium sulfate 7.5%; water 10%.

[0030] A method for preparing an early-strength composite foam concrete foaming agent, comprising the following steps: ①The container is placed in a constant temperature water bath at 70°C; ②The composite foaming component, the early-strength component and water are placed in the container; ③ Stir slowly at 300rpm for 1-5min to make it evenly mixed; ④ Add foam stabilizing components and continue stirring for 1-5min; ⑤ Cool to room temperature to obtain earl...

Embodiment 3

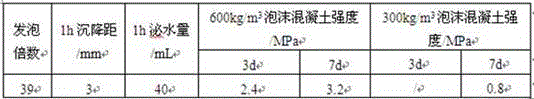

[0035] An early-strength composite foam concrete foaming agent is composed of a composite foam component, a foam-stabilizing component, an early-strength component and water, and the distribution ratio of each component is calculated by mass percentage: composite foam component: 12 Sodium Alkyl Sulfate 18.0%, Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 18.0%, Cocamidopropyl Betaine 36.0%, Tea Saponin 8.0%; Foam Stabilizing Component: Lauryl Alcohol 1.0%; Early Strength Component: Triethanolamine 1.0%, sodium sulfate 4.0%; water 14.0%.

[0036] A method for preparing an early-strength composite foam concrete foaming agent, comprising the following steps: ①The container is placed in a constant temperature water bath at 70°C; ②The composite foaming component, the early-strength component and water are placed in the container; ③ Stir slowly at 200rpm for 1-5min to make it evenly mixed; ④ Add foam stabilizing components and continue stirring for 1-5min; ⑤ Cool to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com