Base plate conveying device

A transmission device and substrate technology, applied in conveyors, transportation and packaging, non-mechanical conveyors, etc., can solve problems affecting the quality of liquid crystal panels, occupying a large area, and easily scratching substrates, etc., to save equipment costs, Easy cleaning and maintenance, stable transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

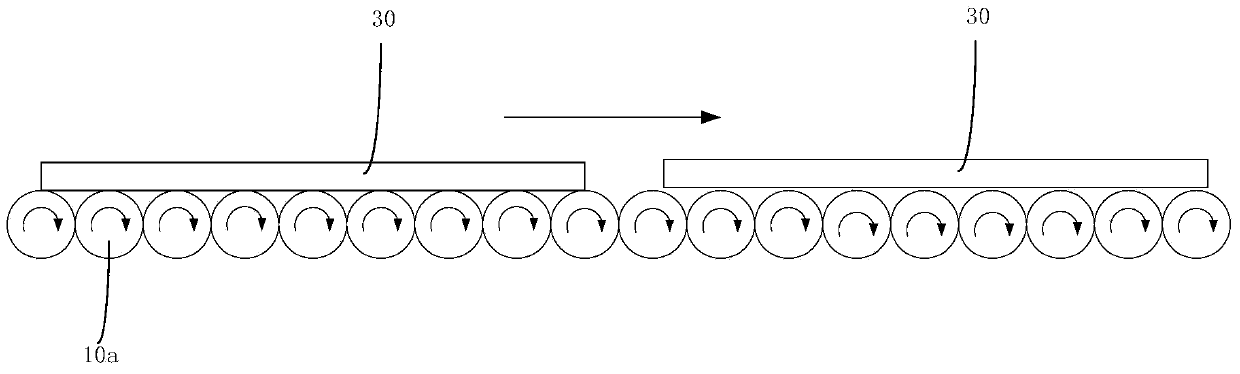

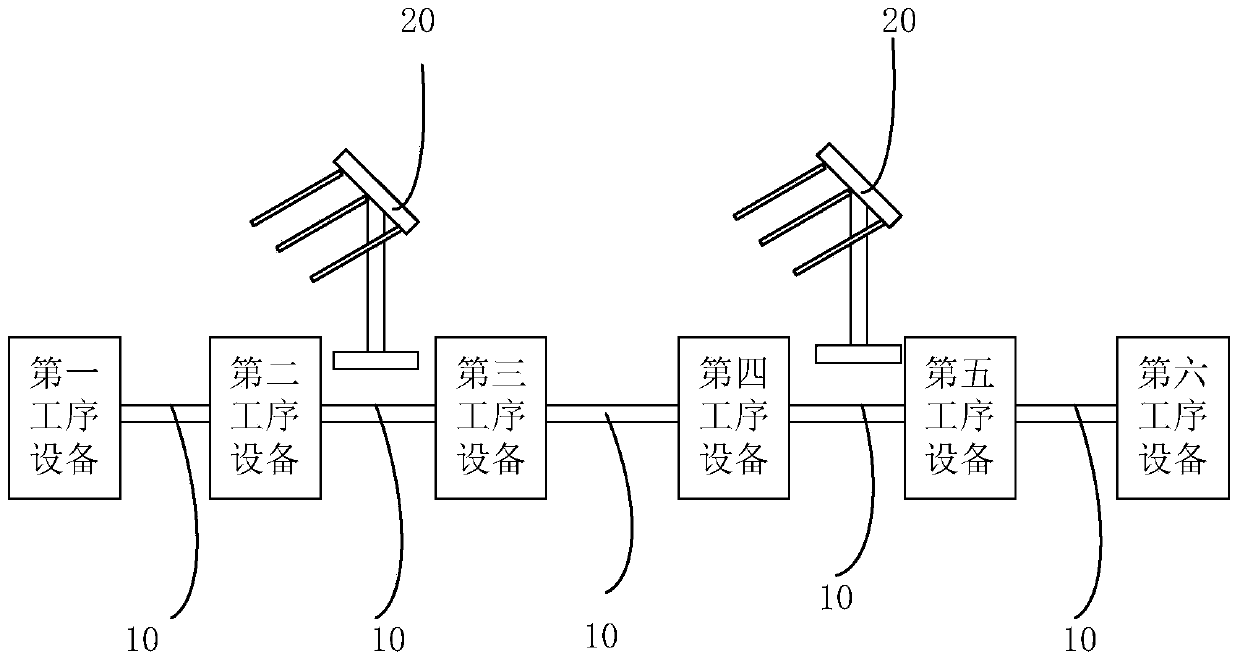

[0033] Aiming at the problem that the substrate conveying device in the prior art adopts the roller conveying method, which is easy to scratch the substrate, and is prone to produce friction dust to affect product quality, the present invention provides a substrate conveying device, which can avoid substrate scratches and reduce friction and dust production occur.

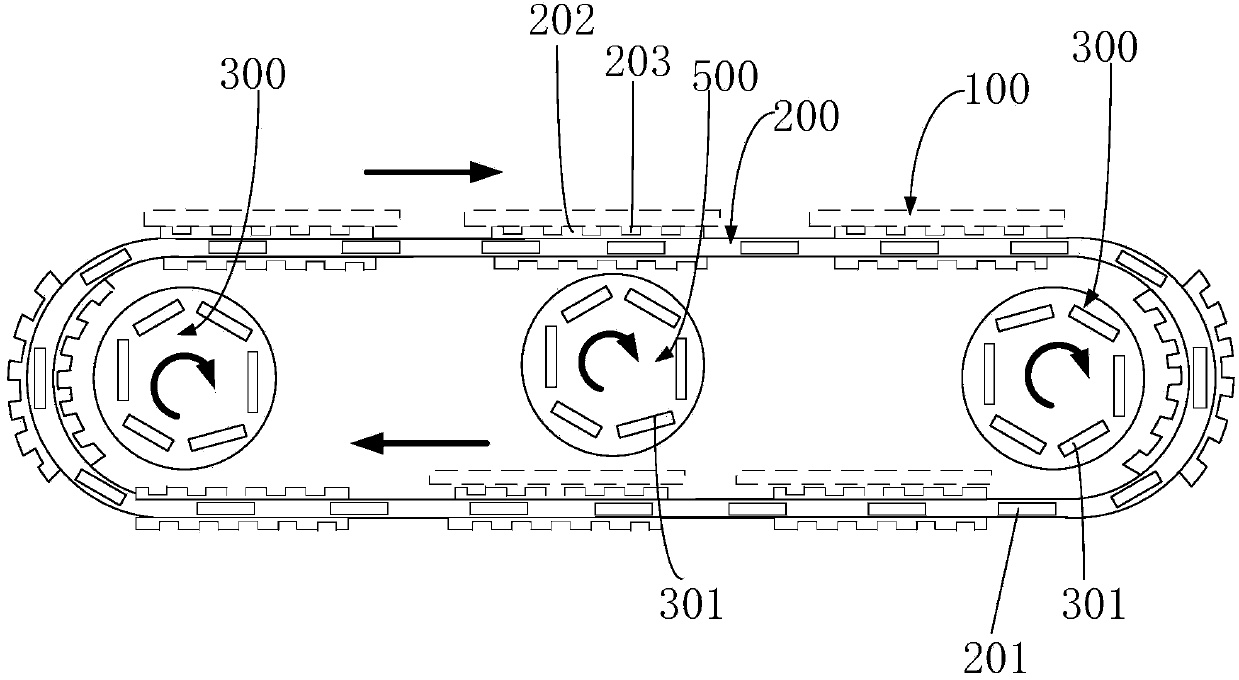

[0034] Such as image 3 with Figure 4 As shown, the substrate transfer device provided by the present invention includes:

[0035] a conveyor belt 200 for carrying the substrate 100;

[0036] At least two maglev driving wheels 300, the conveyor belt 200 is arranged on at least two maglev driving wheels 300;

[0037] Wherein, a plurality of first mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com