Method for manufacturing enhanced thick-walled composite tube

The invention relates to a composite material pipe and a production method technology, which is applied in the field of reinforced thick-walled composite material pipe production, and can solve the problems of insufficient connection strength between layers, inability to meet requirements, delamination and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides a method for manufacturing a reinforced thick-walled composite material pipe, comprising the following steps:

[0022] Laying, preheating and hot pressing the multi-layer prepreg sheets to obtain a laminated composite material sheet having a thickness d;

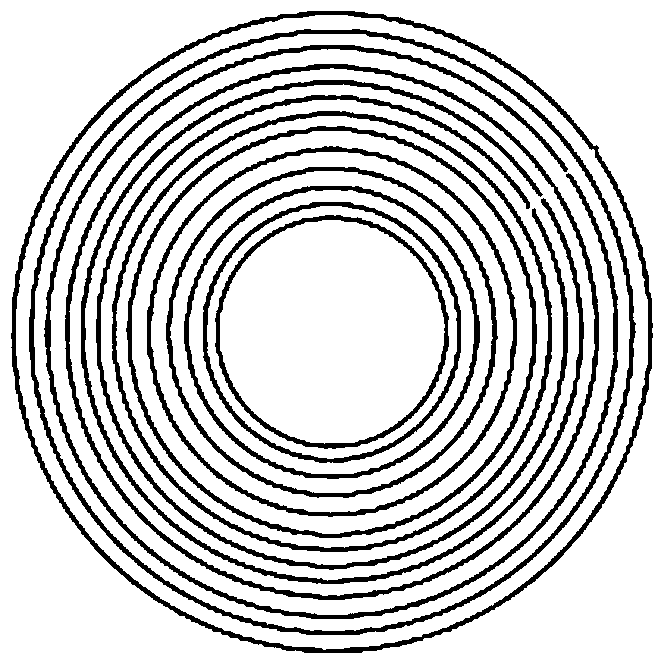

[0023] According to the predetermined outer diameter R 1 Cylindrical profiles are cut out of said laminated composite sheet to obtain outer diameters R 1 A reinforced thick-walled composite tube blank, wherein, the R 1 <d, to ensure the size of the reinforced thick-walled composite tube blank;

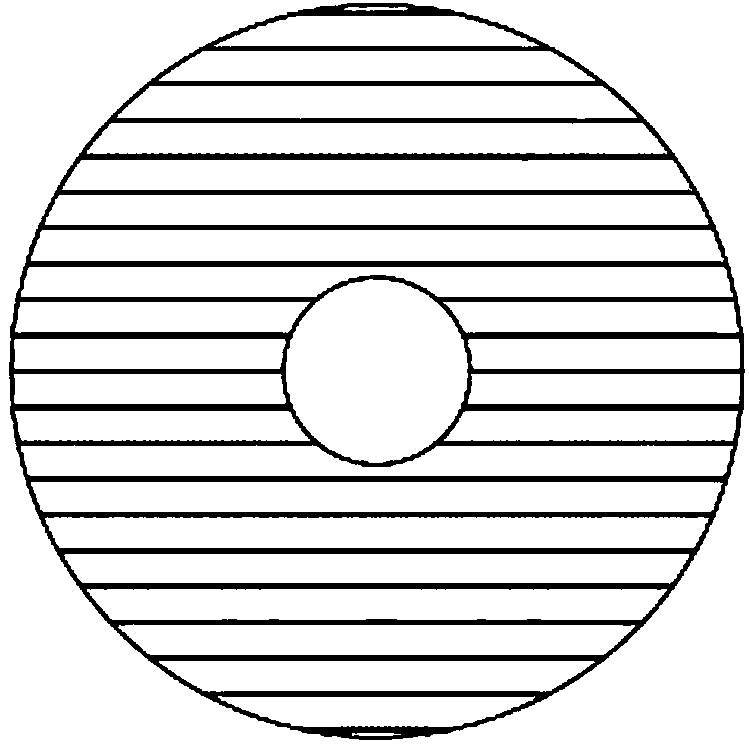

[0024] The reinforced thick-walled composite material tube blank has a hole diameter R along its axis 2 The through-holes form the reinforced thick-walled composite tube, the cross-section of which is as figure 2 shown.

[0025] In the manufacturing method of the reinforced thick-walled composite material pipe, the prepreg sheet is made of three-layer prepreg with laying angles of 0°, 45° and 90° a...

Embodiment 2

[0034] The invention provides a method for manufacturing a reinforced thick-walled composite material pipe, comprising the following steps:

[0035] Laying, preheating and hot pressing the multi-layer prepreg sheets to obtain a laminated composite material sheet having a thickness d;

[0036] According to the predetermined outer diameter R 1 Cylindrical profiles are cut out of said laminated composite sheet to obtain outer diameters R 1 A reinforced thick-walled composite tube blank, wherein, the R 1 <d, to ensure the size of the reinforced thick-walled composite tube blank;

[0037] The reinforced thick-walled composite material tube blank is provided with a through hole with a diameter R2 along its axis to form the reinforced thick-walled composite material tube.

[0038] In the manufacturing method of the reinforced thick-walled composite material pipe, the prepreg sheet is made of three-layer prepreg with laying angles of 0°, 45° and 90° and is hot-pressed by an ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com