Method for reducing NOx in high-temperature calcination by SCR denitration technology adopting carbon-series reduction agent.

A high-temperature calcination and reducing agent technology, applied in the field of air pollutant NOx treatment, can solve the problems of high resource consumption, inactivation, secondary environmental pollution, etc., and achieve the effect of convenient installation and use, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

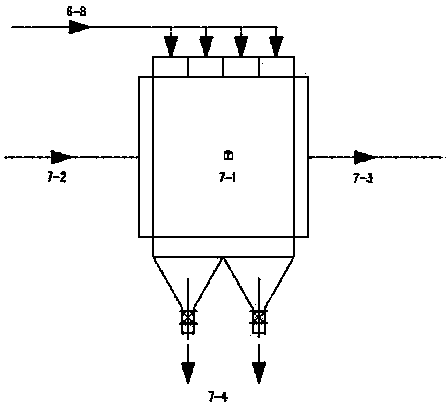

Image

Examples

Embodiment 1

[0046] (1), preparation of carbon-based reducing agent:

[0047] with CO doped 2 The high-temperature air is used as the heat source to pyrolyze raw coal at high temperature, and water or steam is used as a means to adjust the temperature of the reducing gas and reduce the unburned solid carbon suspended in the reducing gas to produce gaseous reducing components mainly composed of carbon monoxide and hydrogen. Carbon-based reducing agent, the chemical equation of the reaction process is:

[0048]

[0049]

[0050] The high-temperature air comes from the tertiary air from the kiln head of the calcining rotary kiln, the air temperature is 900°C, and the added CO 2 CO2 with a concentration of 40% at 150°C after denitrification and purification in this system (at the outlet of the denitrification fan) 2 The volume ratio of flue gas and high-temperature air is 1:4, and then the flue gas enters the high-temperature calcination system in two ways for NOx reduction.

[0051] ...

Embodiment 2

[0061] (1), preparation of carbon-based reducing agent:

[0062] The tertiary wind of the high-temperature calcined carbonate of the rotary kiln is used as the heat source of the carbon reducing agent preparation device through conditioning and temperature control, and the conventional biomass pyrolysis method is used to pretreat the biomass carbon raw material (CxOyHz) in the gasifier Preparation of carbon-based reducing agent by high-temperature pyrolysis; the chemical equation of the reaction process is:

[0063]

[0064] The tertiary wind for the production of cement clinker by carbonate calcination is tempered and temperature controlled-mainly to reduce O 2 content, a moderate increase in CO 2 content, meeting the oxygen deficient condition in the gasifier, the air temperature is 900°C, rich in CO 2 , pyrolyze raw coal or biomass fuel into CO+H in the gasifier under oxygen-deficient conditions 2 , because the temperature of the flue gas used for pyrolysis is adjusta...

Embodiment 3

[0074] (1), the use of CO doped 2 The high-temperature air is used as the heat source to pyrolyze raw coal at high temperature, and water or steam is used as a means to adjust the temperature of the reducing gas and reduce the unburned solid carbon suspended in the reducing gas to produce gaseous reducing components mainly composed of carbon monoxide and hydrogen. Carbon-based reducing agent, the chemical equation of the reaction process is:

[0075]

[0076]

[0077] The high-temperature air comes from the tertiary air from the kiln head of the calcining rotary kiln, the air temperature is 1000°C, and the added CO 2 CO2 with a concentration of 40% at 220°C after denitrification and purification in this system (at the outlet of the denitrification fan) 2 The volume ratio of flue gas and high-temperature air is 1:5, and then the flue gas enters the high-temperature calcination system in two ways for NOx reduction.

[0078](2), primary denitrification combustion

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com