Saving-type daily ration for laying hens during egg laying peak and preparation method thereof

A grain-saving technology during the peak egg production period, which is applied in application, animal feed, animal feed, etc., can solve the problems of inability to achieve the effect of corn-soybean meal-based laying hen diets, the impact of egg quality and flavor, and low economic benefits for farmers. problems, to achieve the best egg quality, reduce breeding costs, and save food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

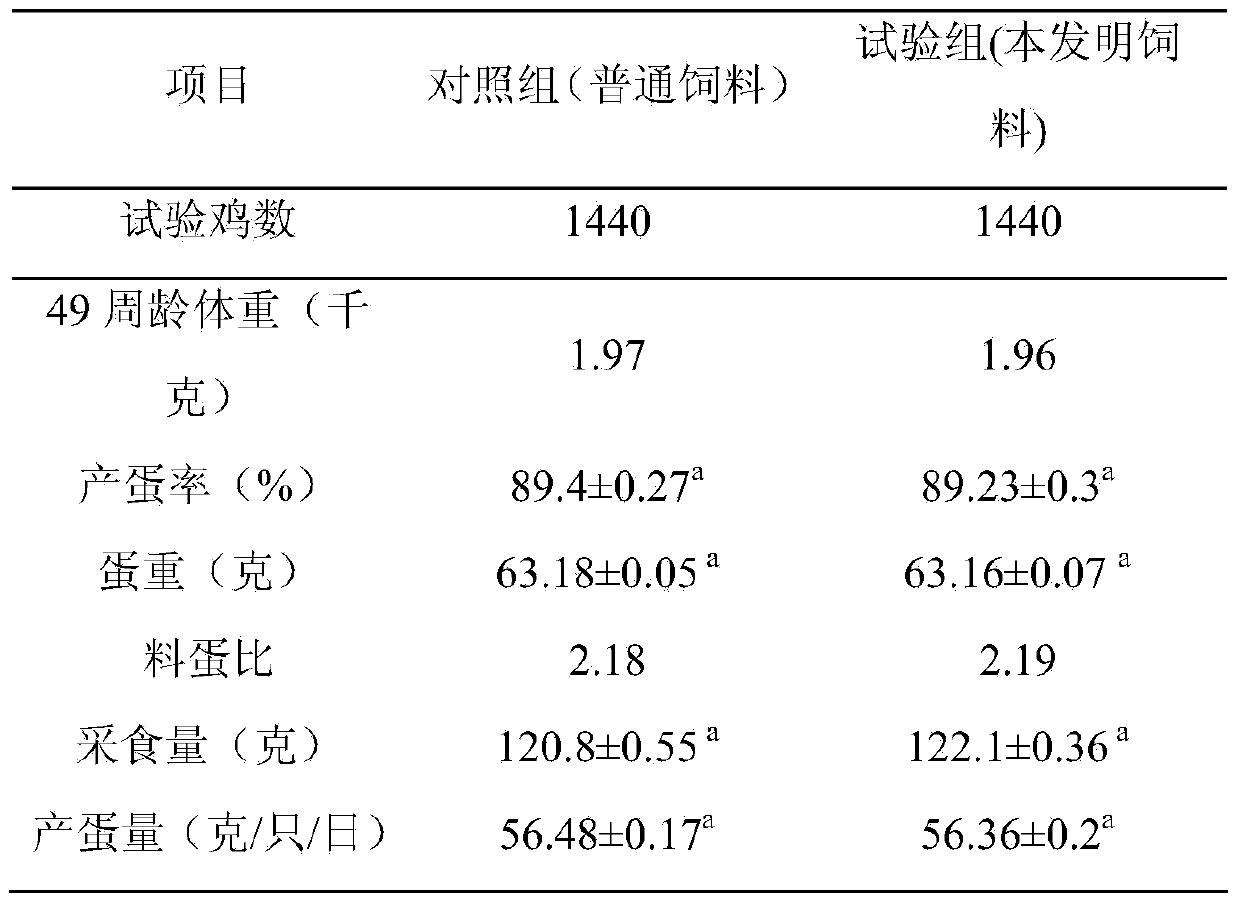

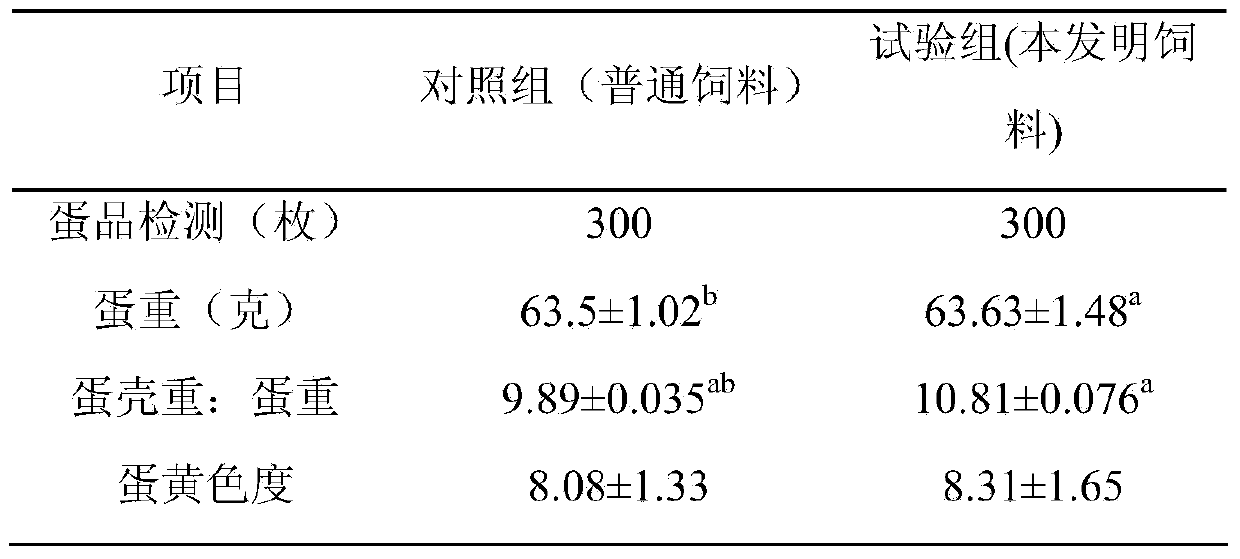

Embodiment 1

[0024] A grain-saving laying hen's ration during the peak egg laying period is composed of the following parts by weight:

[0025] Corn 40, Barley 9, Fermented Palm Kernel Meal 8, Rice Bran 4.5, Rice Bran Meal 5, Soybean Meal 4, Rapeseed Meal 3.5, Peanut Meal 3, Corn DDGS 10.5, Glutamate Residue 3.44, Bentonite 1.5, Rice Oil 2, 10 Mesh stone powder 5, 20-40 mesh stone powder 3.7, calcium hydrogen phosphate 0.6, table salt 0.28, baking soda 0.15, 70% lysine sulfate 0.4, DL-methionine 0.26, L-threonine 0.1, 10% tryptophan 0.05 , prebiotics 0.1, compound enzyme preparation 0.06, choline chloride 0.06, compound premix 0.5.

[0026] Nutritional index: crude protein 16.6%, crude fat 5.83%, crude fiber 4.53% linoleic acid 1.76%, metabolizable energy of laying hens 2772 kcal / kg, calcium 3.5%, total phosphorus 0.53%, available phosphorus 0.28%, salt 0.41% , total amino acids 15.8%, digestible lysine 0.7%, (digestible methionine + digestible cystine) / digestible lysine 89%, digestible t...

Embodiment 2

[0039] A grain-saving laying hen's ration during the peak egg laying period is composed of the following parts by weight:

[0040] Corn 35, Barley 13.22, Fermented Palm Kernel Meal 5, Rice Bran 10, Rice Bran Meal 2.5, Soybean Meal 2, Rapeseed Meal 1.35, Peanut Meal 4, Corn DDGS11, Rice Oil 1.5, Glutamate Residue 3.5, Bentonite 2.5, 10-mesh Stone Powder 4, 20-40 mesh stone powder 2.5, calcium hydrogen phosphate 1, table salt 0.4, baking soda 0.15, 70% lysine sulfate 0.38, DL-methionine 0.35, L-threonine 0.2, 10% tryptophan 0.15, probiotics 0.15, compound enzyme preparation 0.08, choline chloride 0.1, compound premix 0.8.

[0041] Nutritional index: crude protein 16.0%, crude fat 6.7%, crude fiber 4.36%, linoleic acid 2.12%, metabolizable energy of laying hens 2722 kcal / kg, calcium 3.5%, total phosphorus 0.58%, available phosphorus 0.29%, salt 0.42 %, total amino acids 15.6%, digestible lysine 0.68%, (digestible methionine + digestible cystine) / digestible lysine 90%, digestible...

Embodiment 3

[0049] A grain-saving laying hen's ration during the peak egg laying period is composed of the following parts by weight:

[0050] Corn 37, barley 10, fermented palm kernel meal 5, rice bran 8.04, rice bran meal 3, soybean meal 4, rapeseed meal 3.33, corn DDGS11, brewer's yeast 1.0, glutamic acid residue 3.5, bentonite 1.5, stone powder 8.35, calcium hydrogen phosphate 0.6 , salt 0.28, baking soda 0.15, 70% lysine sulfate 0.38, DL-methionine 0.17, L-threonine 0.1, 10% tryptophan 0.07, prebiotic 0.1, compound enzyme preparation 0.06, choline chloride 0.06 , composite premix 0.5.

[0051] Nutritional index: crude protein 16.0%, crude fat 6.7%, crude fiber 4.36%, linoleic acid 2.12%, metabolizable energy of laying hens 2715 kcal / kg, calcium 3.5%, total phosphorus 0.59%, available phosphorus 0.28%, salt 0.42 %, total amino acids 15.6%, digestible lysine 0.68%, digestible methionine + digestible cystine) / digestible lysine 90%, digestible threonine / digestible lysine 78%, Digestibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com