Method for preparing transparent conductive film

A transparent conductive film and substrate technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of complex production process and increased production cost, reduce power consumption and production cost, increase oxygen Effects of Vacancy Concentration and Sheet Resistivity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

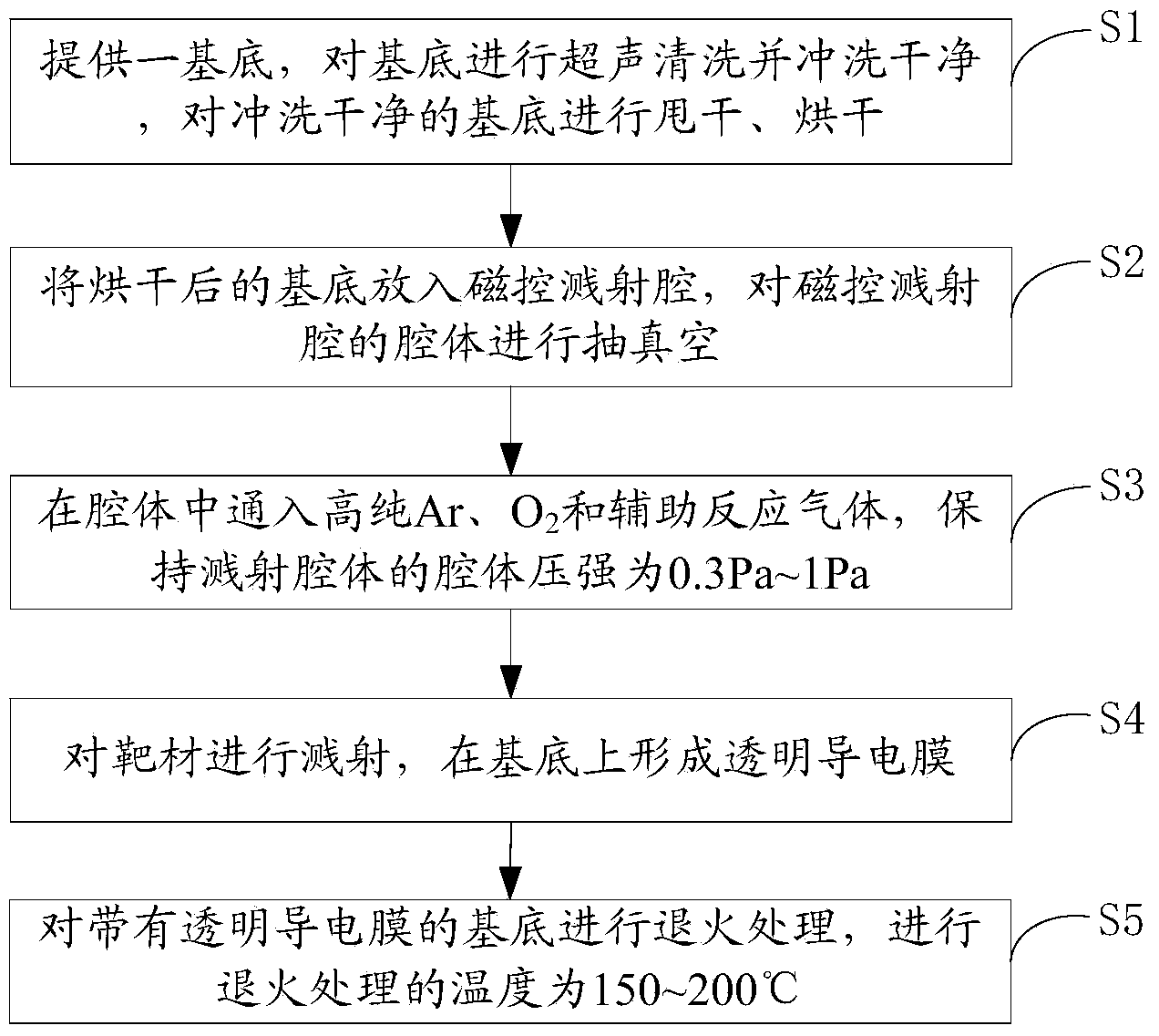

[0045] The specific preparation process of a transparent conductive film provided in this embodiment is as follows:

[0046] Ultra-clear glass was ultrasonically cleaned with alcohol for 5 minutes, then rinsed with deionized water for 2 minutes, then dried and dried;

[0047] Put the dried ultra-clear glass into the magnetron sputtering transition chamber, then evacuate the magnetron sputtering transition chamber to below 10Pa, and transfer the ultra-clear glass to the sputtering deposition chamber;

[0048] Wait until the background vacuum is evacuated to 1×10 -3 Pa, into high-purity Ar, O 2 and H 2 , the flow rates are 380sccm, 20sccm, 100sccm respectively;

[0049] Adjust the flexible guide valve so that the pressure in the sputtering deposition chamber is 0.45Pa, turn on the DC power supply, increase the power supply to 3000W, control the transmission rate to 11.67mm / s, and the sputtering target is an indium tin oxide rotating target;

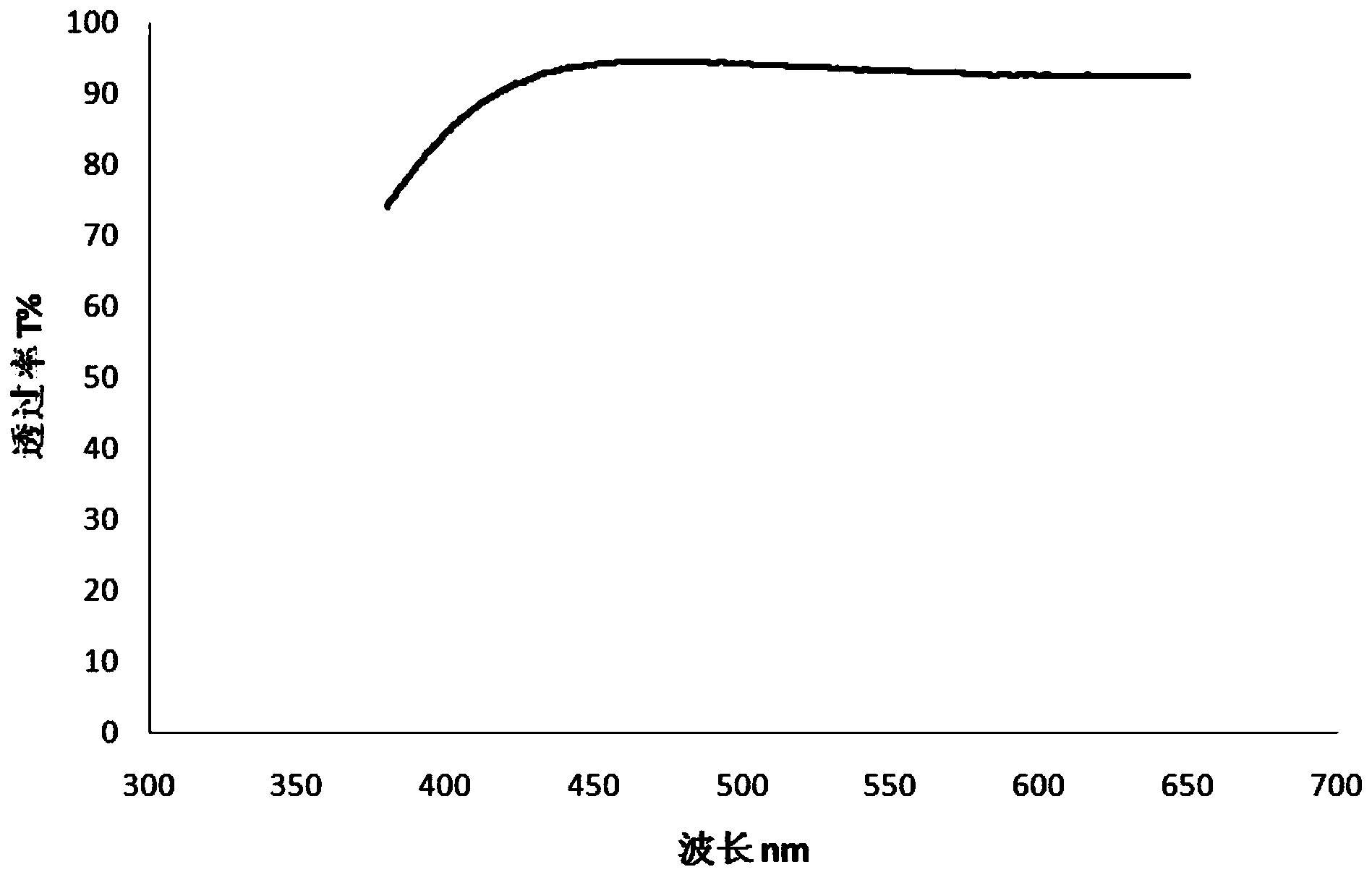

[0050] After the sputtering is c...

Embodiment 2

[0053] The specific preparation process of a transparent conductive film provided in this embodiment is as follows:

[0054] Ultra-clear glass was ultrasonically cleaned with alcohol for 5 minutes, then rinsed with deionized water for 2 minutes, then dried and dried;

[0055] Put the dried ultra-clear glass into the magnetron sputtering transition chamber, then evacuate the magnetron sputtering transition chamber to below 10Pa, and transfer the ultra-clear glass to the sputtering deposition chamber;

[0056] Wait until the background vacuum is evacuated to 1×10 -3 Pa, into high-purity Ar, O 2 and H 2 , the flow rates are 380sccm, 20sccm, 100sccm respectively;

[0057] Adjust the flexible pilot valve so that the pressure in the sputtering deposition chamber is 0.45Pa, turn on the DC power supply, increase the power supply to 4000W, control the transmission rate to 15.56mm / s, and the sputtering target is an indium tin oxide rotating target;

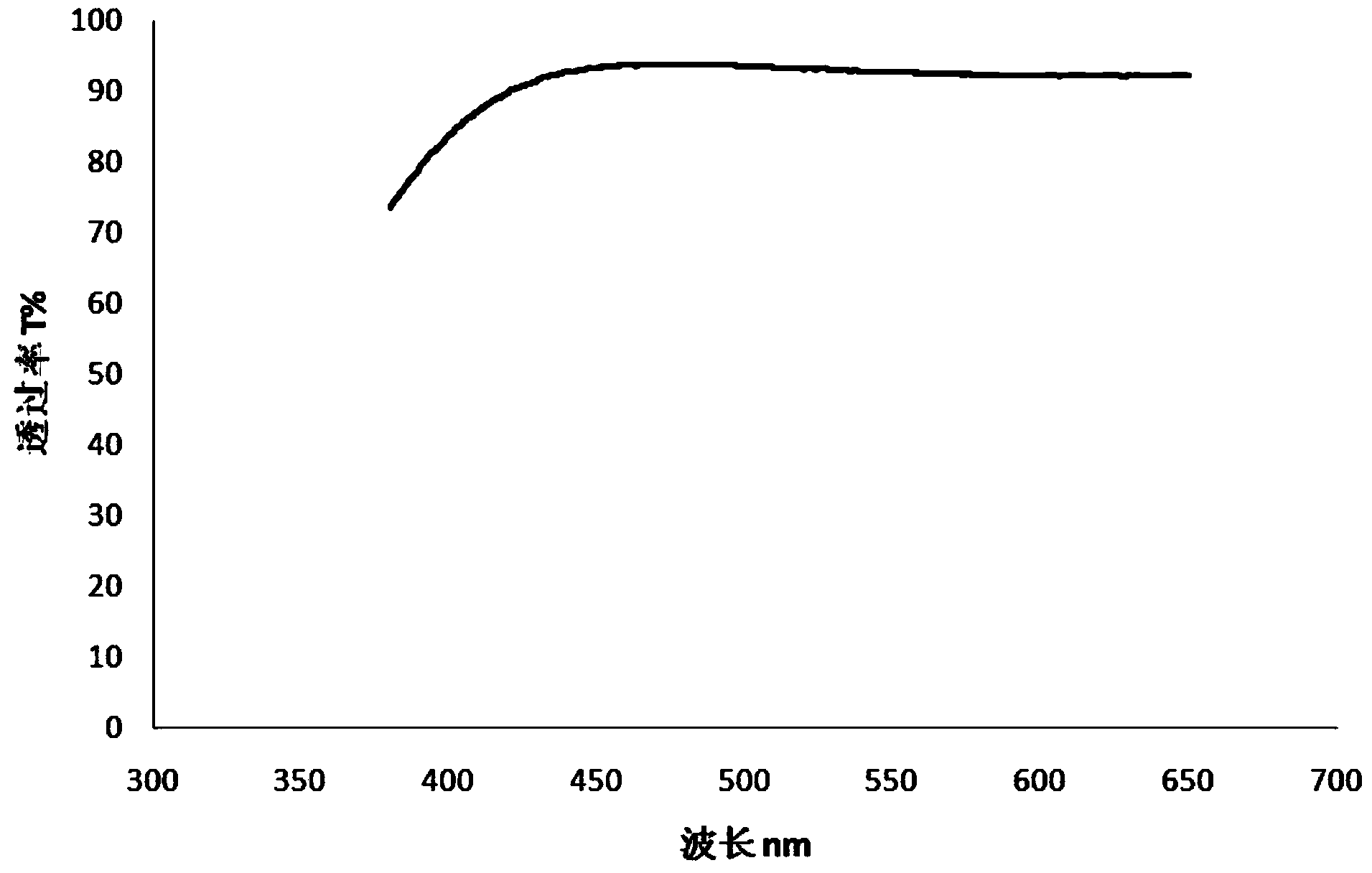

[0058] After the sputtering is c...

Embodiment 3

[0061] The specific preparation process of a transparent conductive film provided in this embodiment is as follows:

[0062] Ultra-clear glass was ultrasonically cleaned with alcohol for 5 minutes, then rinsed with deionized water for 2 minutes, then dried and dried;

[0063] Put the dried ultra-clear glass into the magnetron sputtering transition chamber, then evacuate the magnetron sputtering transition chamber to below 10Pa, and transfer the ultra-clear glass to the sputtering deposition chamber;

[0064] Wait until the background vacuum is evacuated to 1×10 -3 Pa, into high-purity Ar, O 2 and H 2 , the flow rates are 380sccm, 20sccm, 100sccm respectively;

[0065] Adjust the flexible guide valve so that the pressure in the sputtering deposition chamber is 0.45Pa, turn on the DC power supply, increase the power supply to 5000W, control the transmission rate to 19.45mm / s, and the sputtering target is an indium tin oxide rotating target;

[0066] After the sputtering is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com