Grinder with slide guide

A sliding guide and grinding machine technology, which is applied in the field of grinding machines, can solve problems such as impact and poor grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

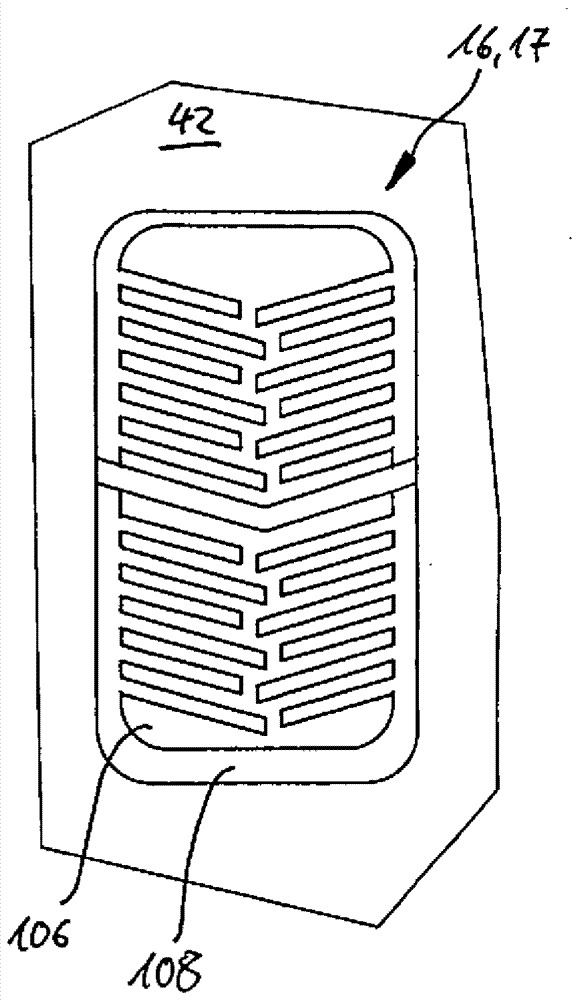

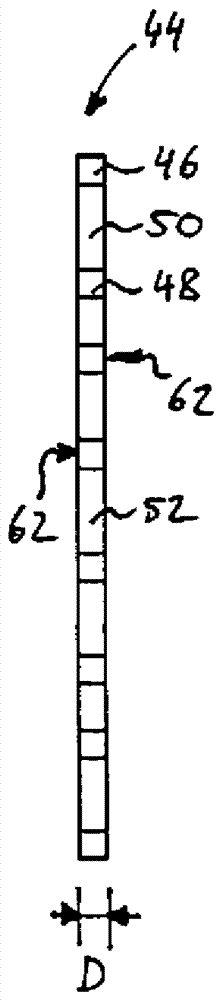

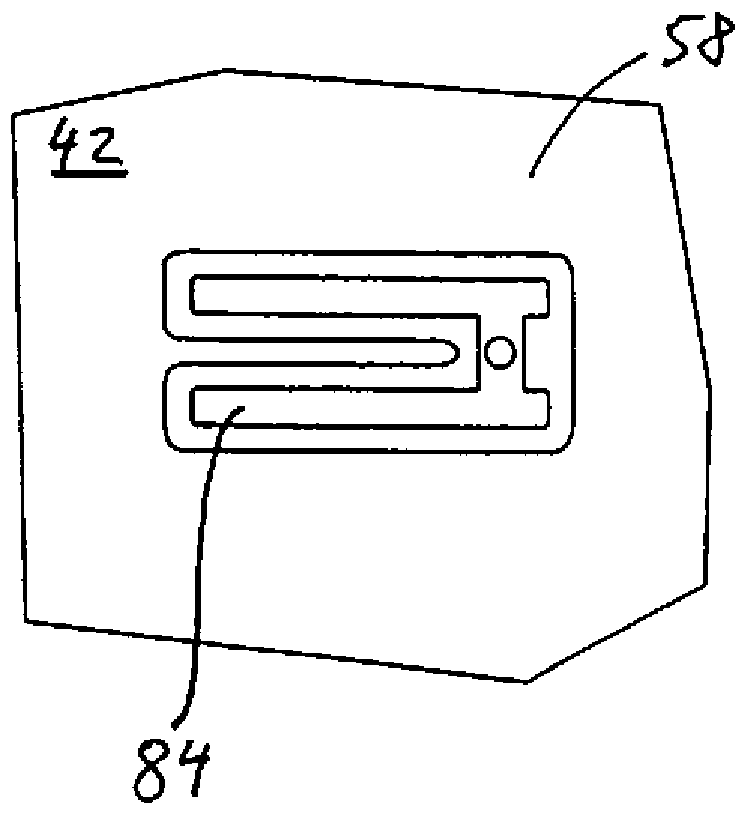

[0049] From Figure 1 to Figure 6 In the overview of the figure, a grinding machine 2 can be seen, which has a base 4, a movable slide 6, a grinding tool unit 8 fixed on the slide 6 and a connection between the base 4 and the slide A linear guide mechanism 10 constructed between 6, by means of which the slide plate 6 can move along the guiding direction F of the linear guide mechanism 10, wherein the linear guide mechanism 10 has at least one bearing method Force-oriented sliding guide 12 and at least one other guide 14 for bearing lateral force, wherein said or each sliding guide 12 respectively comprises two flat guide surfaces 16, 17 facing each other, and wherein At least one of the guide surfaces 16 of the or each slide guide 12 has at least one integrated surface element 18 which has a lower coefficient of friction than the correspondingly adjoining remaining guide surface 20 .

[0050] The grinding machine 2 is sufficiently known from the prior art that a detailed illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com