Preparation method of lithium sulfur battery membrane electrode

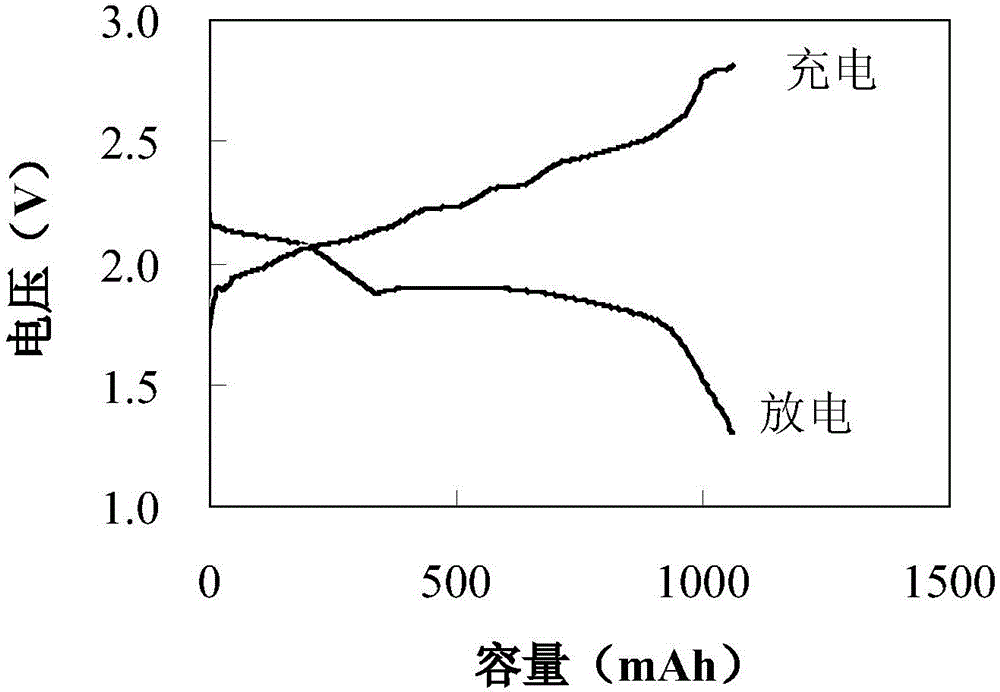

A lithium-sulfur battery and membrane electrode technology, which is applied in battery electrodes, electrode manufacturing, and electrolyte storage battery manufacturing, can solve the problems of lithium-sulfur battery capacity decline, unsatisfactory discharge performance, and poor cycle life, and achieve good electrode reaction reversibility , Improving the electrochemical kinetic performance and the effect of low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a lithium-sulfur battery membrane electrode, specifically comprising the steps of:

[0044] (1) Weigh the carbon carrier and ferrous sulfate, add them to 100mL deionized water, mix with ultrasonic vibration for 30 minutes to dissolve the ferrous sulfate, then heat to evaporate the water and deposit the ferrous sulfate on the surface of the carbon carrier to obtain the product; The product is heated up to 800-1000°C under the protection of nitrogen atmosphere, and reacted for 5 hours to obtain a carbon material with nanometer ferrous sulfide dispersedly distributed on the surface of the carbon carrier;

[0045] Wherein, the mass ratio of carbon carrier and ferrous sulfate is between 1:0.01~0.1, and the addition amount of carbon carrier is 10g, and the addition amount of ferrous sulfate is 0.1~1g; Described carbon carrier is commercial catalyst carbon carrier ; For example, the carbon black produced by Cabot Company is XC72, BP2000 and SP;

[0046]...

Embodiment 1

[0058] Example 1 Preparation of Nanoscale Ferrous Sulfide Loaded Macroporous Carbon Material

[0059] Take acetylene black (10g) and ferrous sulfate (0.1g) by mass ratio 1: 0.01, add to 100mL deionized water, ultrasonic vibration (ultrasonic frequency 40kHz) mixes for 30 minutes to dissolve ferrous sulfate; Depositing ferrous sulfate on the surface of acetylene black particles; raising the temperature of the product to 800° C. for 5 hours under the protection of nitrogen atmosphere; obtaining a carbon material with nanometer ferrous sulfide dispersedly distributed on the surface of acetylene black particles.

Embodiment 2

[0060] Example 2 Cathode material with sulfur loaded on carbon black

[0061] Weigh XC72 carbon black (10g) and ferrous sulfate (0.5g) at a mass ratio of 1:0.05, add them to 100mL deionized water, and mix with ultrasonic vibration (ultrasonic frequency 40kHz) for 30 minutes to dissolve ferrous sulfate; heat to evaporate the water Depositing ferrous sulfate on the surface of carbon black; raising the temperature of the product to 900° C. for 5 hours under the protection of nitrogen atmosphere to react; obtaining a carbon material with nanometer ferrous sulfide dispersedly distributed on the surface of carbon black.

[0062] Grind and mix elemental sulfur with the above-mentioned carbon material containing nano-ferrous sulfide as a sulfur storage material at a mass ratio of 10:1, place it in a 316 stainless steel reactor, heat it to 60°C after vacuuming, and complete the sulfur after 5 hours. load.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com