Method for preparing nanometer silicon conductive polymer composite material for lithium ion batteries

A conductive polymer and lithium-ion battery technology, applied in nanotechnology, battery electrodes, and nanotechnology for materials and surface science, can solve problems such as sudden decrease in specific capacity, large volume effect, and damage to the microstructure of materials. Achieve the effects of improving conductivity, simple preparation process, and good charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

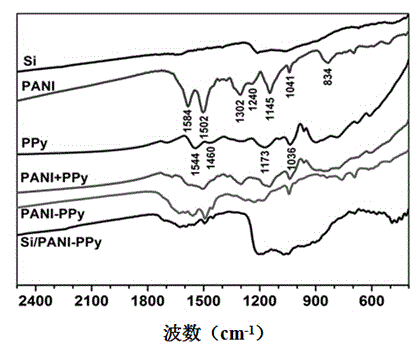

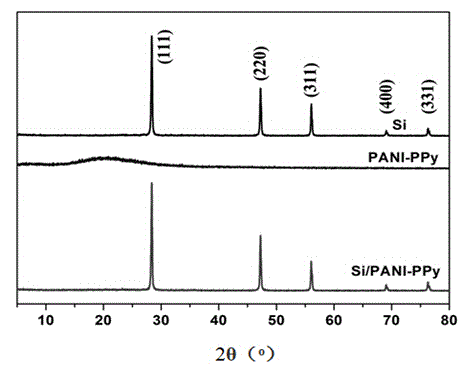

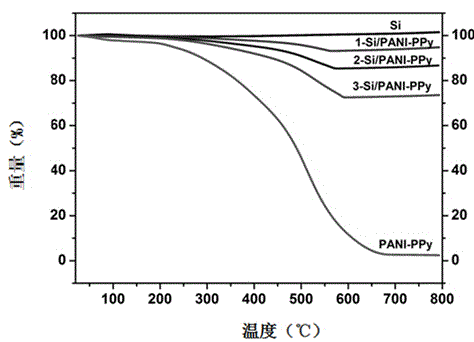

Method used

Image

Examples

Embodiment 1

[0040] Add 0.7500g of nano-silica powder and 0.5143g of sodium p-toluenesulfonate into 250mL of deionized water; dissolve 0.3141g of pyrrole and 0.4359g of aniline in 50mL of absolute ethanol and add them to the above mixture, adjust with 1mol / L hydrochloric acid pH=2, put it into an ultrasonic apparatus for ultrasonic dispersion for 1h, switch to electric stirring, and the stirring speed is 300r / min; weigh 6.4133g (NH 4 ) 2 S 2 o 8 Dissolve in 100mL deionized water, adjust the pH to 2 with 1mol / L hydrochloric acid, slowly add the ammonium persulfate solution into the mixture using a peristaltic pump (30min to complete), then oxidize and polymerize at room temperature for 4h. The suspension was filtered with suction, washed three times with absolute ethanol, and several times with a large amount of deionized water, then vacuum-dried at 60°C for 12 hours, and ground to obtain a nano-silicon conductive polymer composite material.

[0041] Weigh 0.2800g nano-silicon conductive...

Embodiment 2

[0043] Add 0.7508g of nano-silica powder and 0.3429g of sodium p-toluenesulfonate into 250mL of deionized water; dissolve 0.2094g of pyrrole and 0.2906g of aniline in 50mL of absolute ethanol and add them to the above mixture, adjust with 1mol / L hydrochloric acid pH=2, put it into the ultrasonic apparatus for ultrasonic dispersion for 1h, switch to electric stirring, and the stirring speed is 300r / min; weigh 4.2751g (NH 4 ) 2 S 2 o 8 Dissolve in 100mL deionized water, adjust the pH to 2 with 1mol / L hydrochloric acid, slowly add the ammonium persulfate solution into the mixture using a peristaltic pump (30min to complete), then oxidize and polymerize at room temperature for 4h. The suspension was filtered with suction, washed three times with absolute ethanol, and several times with a large amount of deionized water, then vacuum-dried at 60°C for 12 hours, and ground to obtain a nano-silicon conductive polymer composite material.

[0044] Weigh 0.2450g nano-silicon conductiv...

Embodiment 3

[0046] Add 0.7510g of nano-silica powder and 0.7715g of sodium p-toluenesulfonate into 250mL of deionized water; dissolve 0.4712g of pyrrole and 0.6539g of aniline in 50mL of absolute ethanol and add them to the above mixture, adjust with 1mol / L hydrochloric acid pH = 2, put it into an ultrasonic apparatus for ultrasonic dispersion for 1 hour, switch to electric stirring, and the stirring speed is 300r / min; weigh 9.6209g (NH 4 ) 2 S 2 o 8 Dissolve in 100mL deionized water, adjust the pH to 2 with 1mol / L hydrochloric acid, slowly add the ammonium persulfate solution into the mixture using a peristaltic pump (30min to complete), then oxidize and polymerize at room temperature for 4h. The suspension was filtered with suction, washed three times with absolute ethanol, and several times with a large amount of deionized water, then vacuum-dried at 60°C for 12 hours, and ground to obtain a nano-silicon conductive polymer composite material.

[0047] Weigh 0.2810g nano silicon cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com