Inorganic nano particle hybridized polyolefin microporous membrane and preparation method thereof

A technology of inorganic nanoparticles and polyolefin microporous membranes, applied in the field of diaphragm products, can solve problems such as thermal deformation, poor thermal stability, battery safety accidents, etc., achieve improved heat resistance and shrinkage resistance, and simple process flow Ease of operation and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the present invention, on the basis of the previous technical scheme, specifically, the preparation method of lipophilic electrically insulating inorganic nanoparticles in step (1) is as follows: the inorganic nanopowder is dispersed in water or alcohol solution by ultrasonic, The volume ratio of water and alcohol in the alcohol solution is 1:5-1:0; select a modifier or coupling agent to prepare the solution, add it to the inorganic nanoparticle slurry and mix, heat up to 80-100°C and stir at constant temperature for 2-5 hours; stop the reaction, filter with suction, extract and wash with absolute alcohol, dry and grind the obtained modified inorganic nanoparticles in vacuum at 80-100° C. for later use.

[0034] In the preparation method of the present invention, on the basis of the previous technical scheme, the specific modifier or coupling agent is one of silane coupling agent, titanate coupling agent or aluminate coupling agent, anionic surf...

Embodiment 1

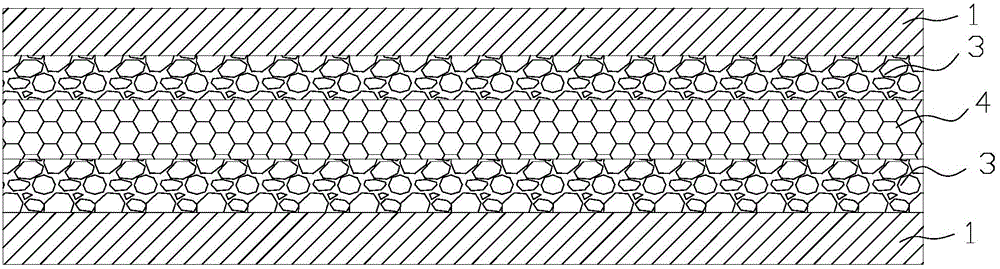

[0038] Firstly, silane coupling agent was used to modify the lipophilicity of alumina to obtain lipophilic nano-alumina. Add diluent and ultra-high molecular weight polyethylene in a certain proportion to twin-screw extruder B for plasticization and blending; add modified alumina to paraffin oil for heating and ultrasonic dispersion, and add double Screw extruder A plasticizes and blends. The melt formed by extruders A and B passes through the die head and quenching roll to form an oil film. The oil film is prepared by biaxial stretching, extraction, heat setting and other processes to prepare a microporous membrane with inorganic nanoparticle hybrid ultra-high molecular weight polyethylene, refer to figure 1 , the polyolefin layer 1 on the upper and lower surfaces, and the inorganic nanoparticle hybrid layer 2 between the polyolefin layers on the upper and lower surfaces. The nano-hybrid microporous membrane of ABA structure is a diaphragm with a thickness of 12±1 μm, a por...

Embodiment 2

[0040] Firstly, lipophilic aluminum nitride was modified by silane coupling agent to obtain lipophilic nano-aluminum nitride. Add diluent and ultra-high molecular weight polyethylene in a certain proportion to twin-screw extruder B for plasticization and blending; add modified aluminum nitride to paraffin oil to heat, ultrasonically disperse, and add in a certain proportion to ultra-high molecular weight polyethylene Twin-screw extruder A plasticizes and blends. The melt formed by extruders A and B passes through the die head and quenching roll to form an oil film. The oil film is prepared by biaxial stretching, extraction, heat setting and other processes to prepare a microporous membrane with inorganic nanoparticle hybrid ultra-high molecular weight polyethylene, refer to figure 1 , the polyolefin layer 1 on the upper and lower surfaces, and the inorganic nanoparticle hybrid layer 2 between the polyolefin layers on the upper and lower surfaces. The nano-hybrid microporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com