Method for preparing magnetic particle with level hole structure

A technology of magnetic particles and hierarchical holes, which is applied to the magnetism of organic materials/organic magnetic materials, inductance/transformer/magnet manufacturing, nanotechnology for materials and surface science, etc., can solve single problems, achieve simple process, The effect of uniform particle size and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

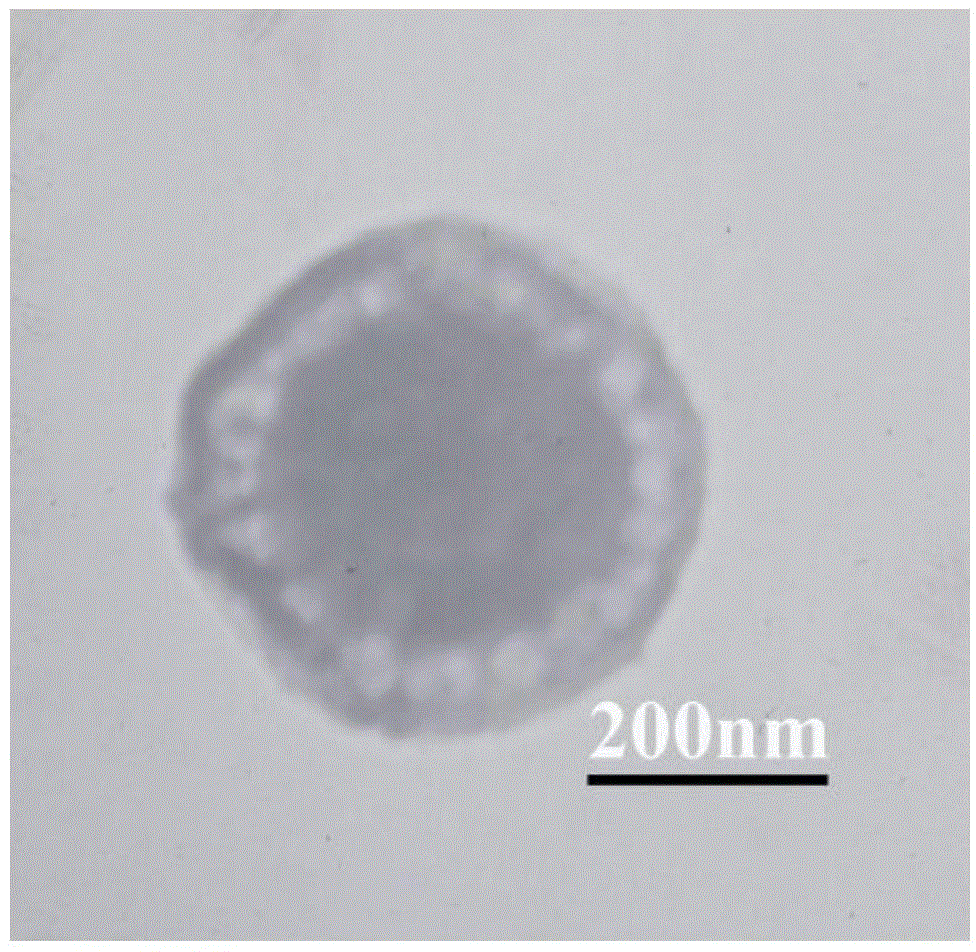

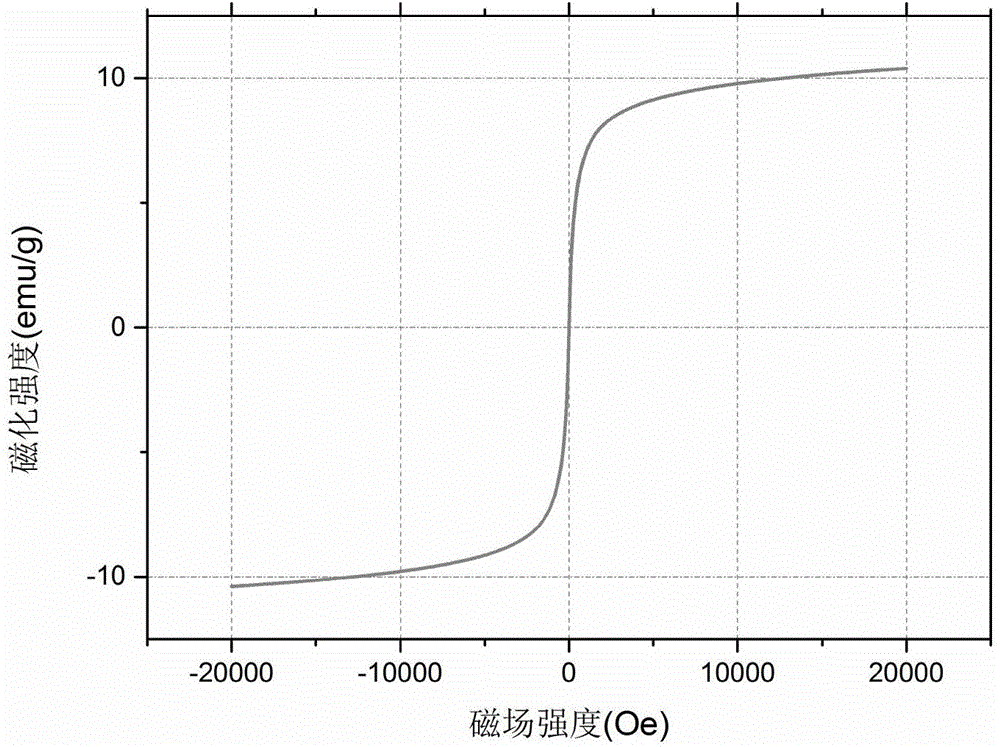

[0024] Preparation of egg yolk-eggshell structured carbon micro-nano particles. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution, measure 15ml polymer hollow microspheres, stir and mix and place at room temperature for 24 Hour. Centrifugal cleaning, adding 15ml of water and concentrated sulfuric acid, stirring and mixing evenly, standing at room temperature for 12 hours, centrifuging and cleaning to obtain particles with a core-shell structure. Add 5 g of saturated ferric chloride solution into 100 ml of boiling water and continue to boil until the solution turns reddish brown, cool down, and add 0.5 g of tetraethyl orthosilicate. The above-mentioned core-shell particle product was slowly added dropwise, and continued to boil for 1 hour. After the reaction was completed, it was washed and centrifuged. The sandwich structure composite particles of resin-polymer-m...

Embodiment 2

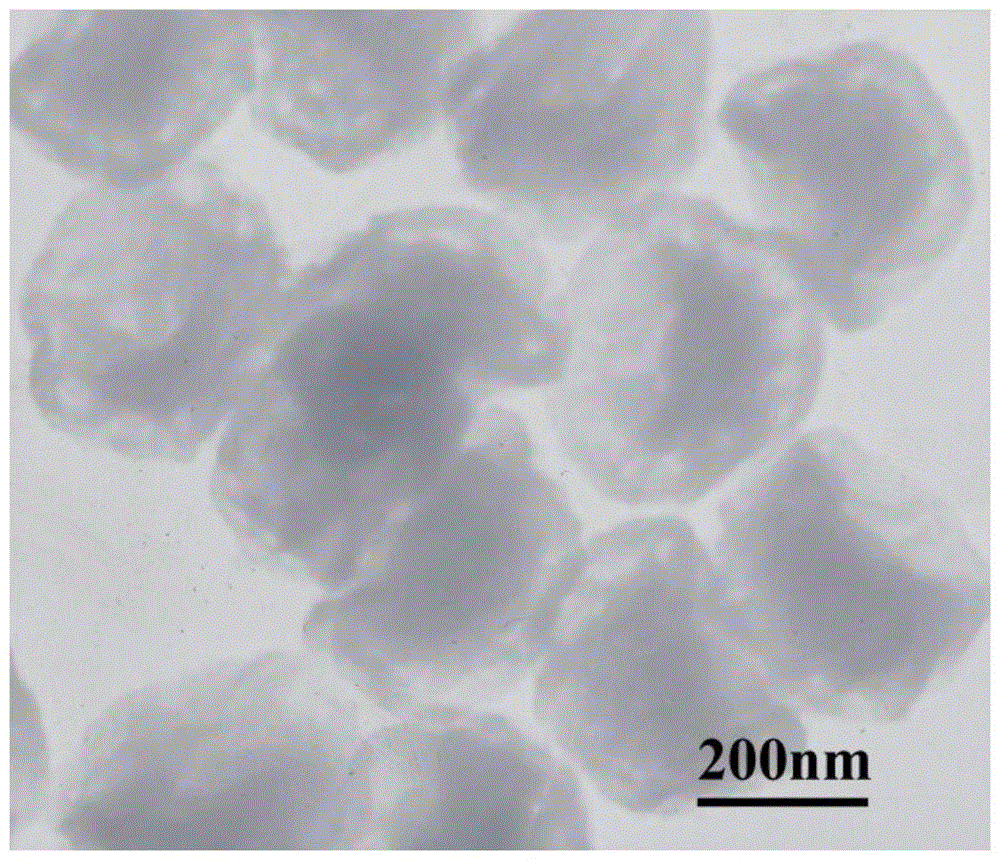

[0027] Preparation of egg yolk-eggshell structure micro-nano carbon particles. Weigh 7.76g resorcinol, 11ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution, measure 15ml polymer hollow microspheres, stir and mix and place at room temperature for 24 hours . Centrifugal cleaning, adding 15ml of water and concentrated sulfuric acid, stirring and mixing evenly, standing at room temperature for 12 hours, centrifuging and cleaning to obtain particles with a core-shell structure. Add 10g of saturated ferric chloride solution to 100ml of boiling water and continue to boil until the solution turns reddish brown, cool down, and add 0.2g of tetraethyl orthosilicate. The above-mentioned core-shell particle product was slowly added dropwise, and continued to boil for 3 hours. After the reaction was completed, it was washed and centrifuged. The sandwich structure composite particles of resin-polymer-magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com