A cylindrical horizontal atmospheric pressure enhanced leaching tank

A technology of enhanced leaching and cylindrical body, applied in the direction of improving process efficiency, etc., can solve the problems of difficult expansion of production capacity and equipment expansion, etc., and achieve the effect of increasing reaction opportunities, no waste of resources, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

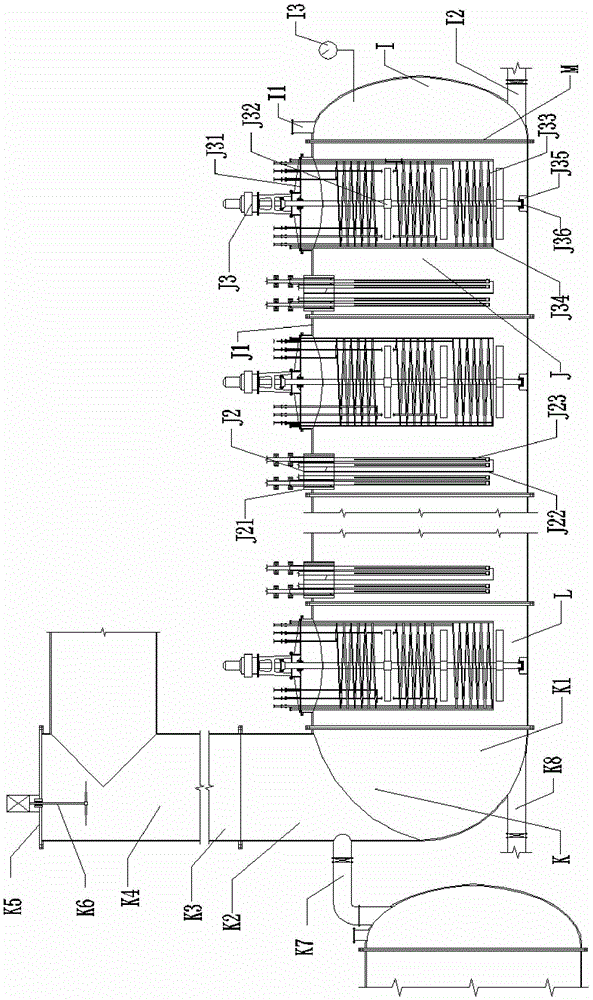

[0044] The cylindrical horizontal atmospheric pressure enhanced leaching tank described in the present invention has components and connection methods as follows.

[0045] 1. General components and connections

[0046] Such as figure 1 As shown, a cylindrical horizontal atmospheric pressure enhanced leaching tank,

[0047] Including the groove head I, the groove body J, the groove end head K and the half groove body L, the ends of the groove head I, the groove body J, the groove end head K and the half groove body L are all provided with legal Flange M, between the two through the flange sealing connection;

[0048] At least one feeding port I1 is arranged on the top of the groove head I, a discharge port I2 is arranged on the bottom of the groove head I, and an air pressure gauge I3 is arranged on the groove head I;

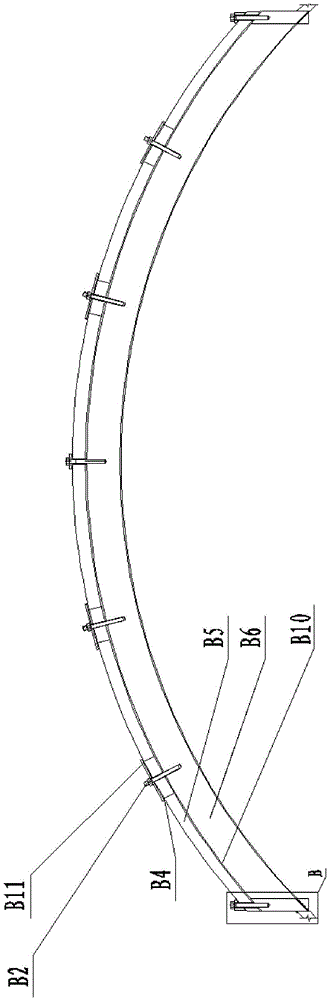

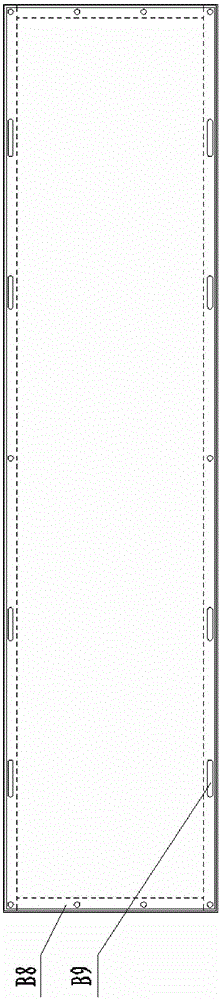

[0049] The tank body J includes a tank cylinder J1, a partition assembly J2 and a stirring assembly J3. The upper part of the tank cylinder J1 is provided wi...

Embodiment 2

[0075] The structural feature of the leaching tank of the present invention is that the tanks with flanges are connected one by one with flanges, and the number of connections can be determined according to the needs, so it can be made into a super-large cylindrical horizontal atmospheric pressure enhanced leaching tank. The length of the tank body of each section is equivalent to a "stirring and mixing chamber", but the "stirring and mixing chamber" is not bounded by the boundary of the connecting flange, but by the partition. In order to reduce the number and area of openings in the tank, the heat exchange tubes are installed on both sides of the partition, so that the partition and the heat exchange tubes use the same installation port. The mixer of the "stirring mixing chamber" must be installed in the middle of the two partitions.

[0076] According to the required processing capacity, design a full-lined polytetrafluoroethylene temperature-resistant and anti-corrosion ...

Embodiment 3

[0082] Using sulfuric acid atmospheric pressure enhanced leaching process, leaching laterite nickel ore in a cylindrical horizontal leaching tank can achieve a good leaching effect, which is manifested in short leaching time, large processing capacity, and high leaching rate of nickel, cobalt and other useful elements.

[0083] Adopt embodiment 2 leaching tank, pack 20 tons of ore by every 100 cubic meters of volume, 90% effective volume 1415 cubic meters, can once load ore (1415÷100×20=) 283 tons. The maximum conveying capacity of 300ZD-60 slurry pump is 2400m 3 / h=40m 3 / min, the ball mill slurry of 283 tons of ore is about (283×3=)849m 3It takes time (849÷40=) 21.225≈25min to add the ball mill pulp, and it needs to add concentrated sulfuric acid (283÷1.8=) 157.2≈157m 3 , the pumps conveying concentrated sulfuric acid generally do not exceed 500m 3 / h. Adding concentrated sulfuric acid directly into the ball mill pulp will cause the temperature to rise from room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com