Preparation method of dialkylphosphinic acid extracting agent

A technology of dialkylphosphine and extractant, which is applied in the field of preparation of dialkylphosphinic acid extractant, can solve the problems of limited application, short reaction route, high equipment requirements, etc., and achieve cost reduction and low reaction requirements , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

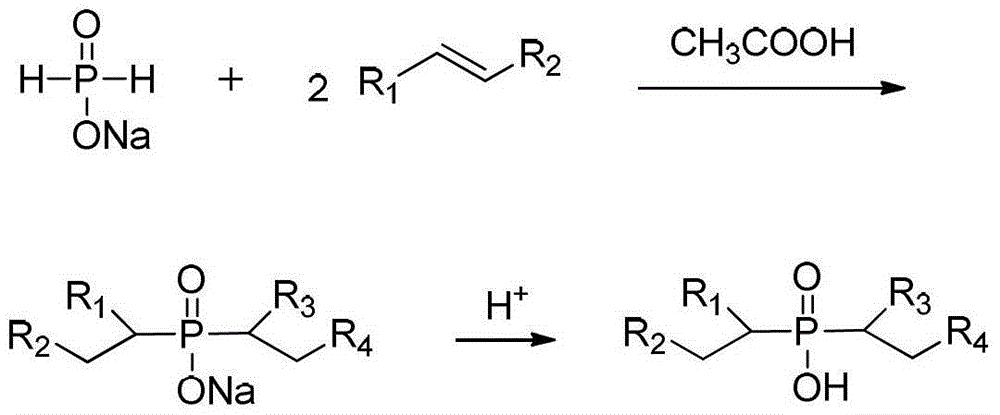

Method used

Image

Examples

Embodiment 1

[0021] 1) Synthesis of mixed olefins

[0022] Put 50g of α-octene, 800g of α-decene, and 150g of α-dodecene into a stirred 2L normal-pressure reaction flask, add 500g of 5% hydrochloric acid, then add 1g of chromocene, start stirring and heat up to At about 65°C, heat-preserve and stir for 3 hours, let stand, and separate the water layer to obtain reformed multi-branched olefins, that is, mixed olefins.

[0023] 2) Synthesis of dialkylphosphinic acid

[0024] Put 106g of sodium hypophosphite and 106g of glacial acetic acid into the normal-pressure reaction kettle brought back to the condenser in turn, start the stirring and heater, raise the temperature to 70°C, and add 300g of reformed mixed olefins after the sodium salt is completely dissolved , then add 10g of di-tert-butyl peroxide, raise the temperature to reflux (about 120°C), and keep it warm for 5 hours; add 10g of di-tert-butyl peroxide again, and keep it warm for 5 hours; repeat this 2 times, the total reaction time...

Embodiment 2

[0027] EXTRACTION AND SEPARATION EXPERIMENT OF MIXED DIALKYL PHYSININIC ACID ON NICKEL AND COBALT

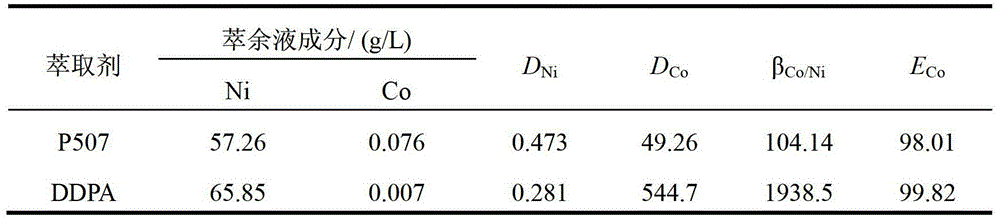

[0028] The comparison of table 1 synthesis dialkyl phosphinic acid mixture and P507 nickel-cobalt separation effect

[0029]

[0030] Experimental conditions: Feed liquid—Co3.82g / L, Ni84.34g / L, pH=4.21, sulfate medium; organic phase—20% extractant + sulfonated kerosene, saponification rate 70%; grade—2 grade; Ratio O / A=1:1; mixing time—4min; temperature—12°C.

[0031] Experimental results:

[0032] The result shows that under the same extraction conditions, the dialkyl hypophosphorous acid mixture synthesized according to embodiment example 1 is compared with P507, and the extraction separation coefficient is higher by an order of magnitude. Under the same extraction conditions, the extraction performance of DDPA is better than P507.

Embodiment 3

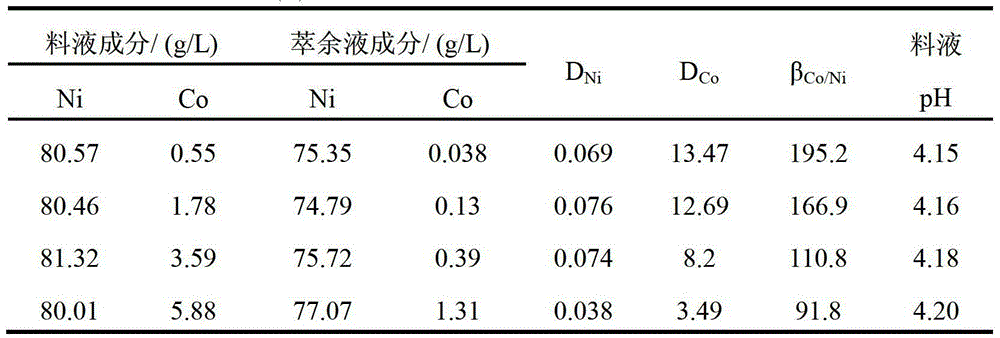

[0034] Table 2. Test results of separation of nickel and cobalt from dialkylphosphinic acid mixtures under different Co(II) concentrations

[0035]

[0036] Test conditions: feed liquid pH=4.16, sulfate medium; organic phase—15%DDPA+sulfonated kerosene, saponification rate 70%; phase O / A=1:1; mixing time—4min; temperature—14°C.

[0037] test results:

[0038] Under the condition that the concentration of nickel ions in the stock solution is basically constant, the separation coefficient decreases with the increase of the concentration of Co(II) in the stock solution. It shows that DDPA is suitable for extracting and separating nickel and cobalt from solutions with low Co / Ni ratio, which reflects the excellent performance of the extractant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com