Four-column hydraulic press

A hydraulic press and hydraulic technology, which is applied in the field of forging machinery, can solve the problems affecting the pressing efficiency and quality of hydraulic presses, and the inability to grasp and control the pressure of hydraulic presses, and achieve the effects of precise pressure control, uniform pressure, and accurate pressure signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

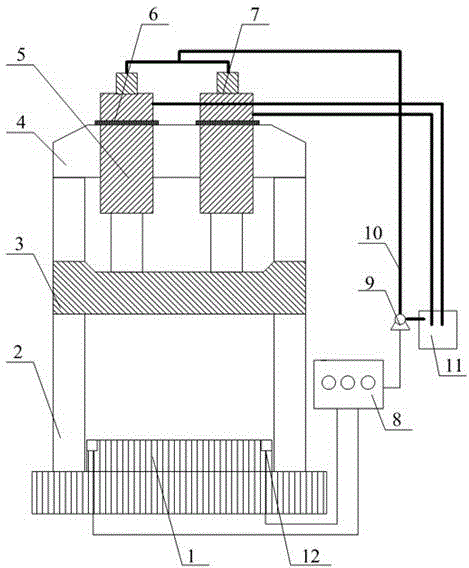

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the four-column hydraulic press of the present invention includes a machine base 1 , a column 2 , an upper beam 4 , a movable beam 3 , a hydraulic cylinder 5 and a control unit 8 . Among them, there are 4 upright columns 2, and the 4 upright columns 2 are fixedly installed on the machine base 1, the upper beam 4 is fixedly installed on the top of the upright column 2, and the movable beam 3 is set on the upright column 2; there are 2 hydraulic cylinders 5, which are fixed and installed side by side through nuts 6 On the upper beam 4, the output rod of the hydraulic cylinder 5 is fixedly connected with the movable beam 3, which drives the movable beam 3 to move up and down along the column 2. The oil inlet hole 7 on the top of the hydraulic cylinder 5 is connected to the plunger pump 9 through the oil pipe 10, and the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com