Liquid metal wetting agent and preparation method for composite material

A technology of liquid metal and complex, applied in the direction of coating, etc., can solve the problems of difficulty in waste liquid treatment and increase of treatment cost, and achieve the effect of environmental protection, low production cost and good effect in the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

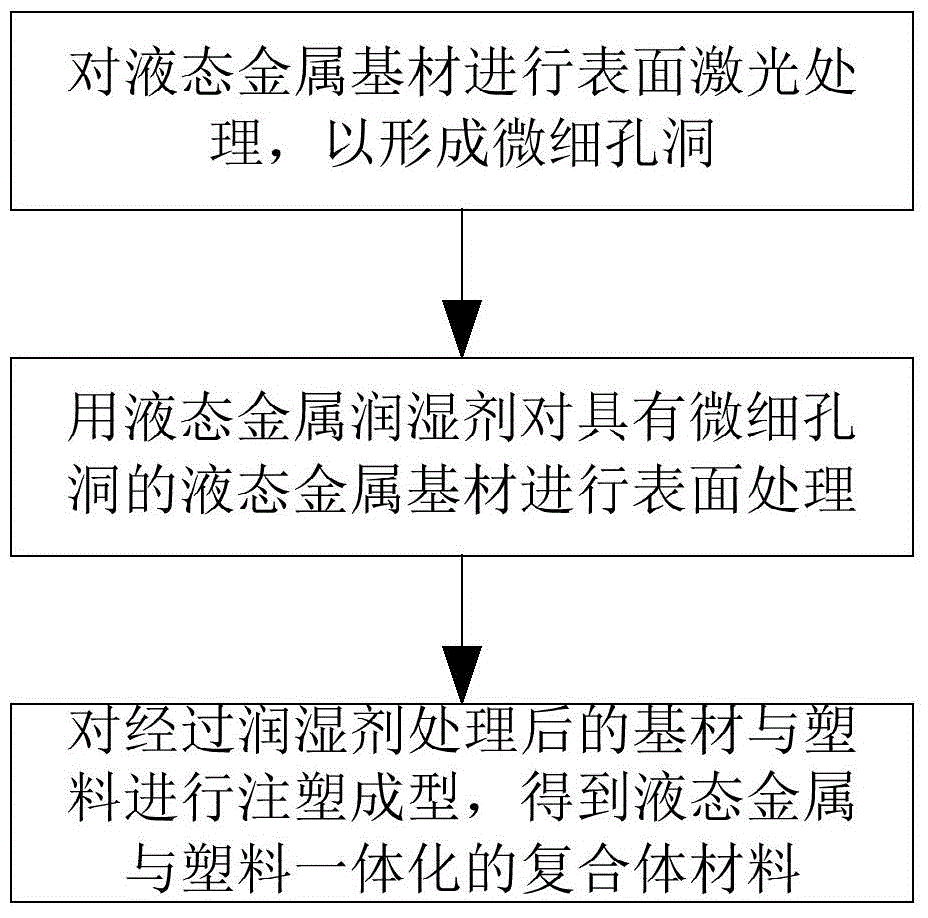

[0036] refer to figure 1 , according to an embodiment of the present invention, the preparation method of the composite material includes the following steps:

[0037] Surface laser treatment of liquid metal substrates to form tiny holes;

[0038] Surface treatment of liquid metal substrates with fine pores with liquid metal wetting agents;

[0039] Injection-molding the liquid metal base material and plastic treated with the liquid metal wetting agent to obtain a composite material integrating liquid metal and plastic;

[0040] Wherein, the liquid metal wetting agent contains an organic modifier for improving the difference in surface tension coefficient between the liquid metal substrate and the plastic.

[0041] The materials involved in the practice of the method of the present invention are as follows.

[0042] 1. Liquid metal: It can be a shaped liquid metal substrate prepared by copper mold suction casting method, liquid quenching method, sputtering method, spray gun...

Embodiment 1

[0063] Preparation of liquid metal wetting agents:

[0064] In 1000 parts of solvent, wherein 350 parts of water, 250 parts of ethanol, 400 parts of ethylene glycol monomethyl ether, add the raw material that has following weight ratio:

[0065] 1) 82 parts of concentrated hydrochloric acid;

[0066] 2) 240 parts of organic modifier

[0067] Among them: 160 parts of maleic acid + 80 parts of malic acid.

[0068] The preparation method of the liquid metal composite material specifically includes the following steps:

[0069] 1) Provide a shaped liquid metal substrate.

[0070] 2) Carry out chemical decontamination treatment on the liquid metal substrate with a cleaning agent to remove the dirt on the metal surface; the chemical decontamination temperature is 80°C, and the decontamination time depends on the specific effect.

[0071] 3) Perform surface ultraviolet laser treatment on the liquid metal after decontamination treatment to form holes with an opening diameter of 10...

Embodiment 2

[0078] Preparation of liquid metal wetting agents:

[0079] In 1000 parts of solvent, wherein 350 parts of water, 350 parts of ethanol, 300 parts of ethylene glycol monobutyl ether, add the raw material that has following weight ratio:

[0080] 1) 265 parts of inorganic acid

[0081] Among them: 200 parts of concentrated hydrochloric acid + 65 parts of concentrated phosphoric acid;

[0082] 2) 150 parts of organic modifier

[0083] Among them: 105 parts of maleic acid + 45 parts of malic acid.

[0084] The preparation method of liquid metal composite material specifically comprises the following steps:

[0085] 1) Provide a shaped liquid metal substrate.

[0086] 2) Carry out chemical decontamination treatment on the liquid metal substrate with a cleaning agent to remove the dirt on the metal surface; the chemical decontamination temperature is 80°C, and the decontamination time depends on the specific effect.

[0087] 3) Perform surface ultraviolet laser treatment on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com