Online detection and correction machining method for enveloping worm tooth surface

A technology of toroidal worm and processing method, which is applied in the direction of worm, metal processing equipment, metal processing machinery parts, etc., and can solve the problems that hinder the large-scale promotion and wide application of toroidal worm transmission, low precision of tooth surface, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

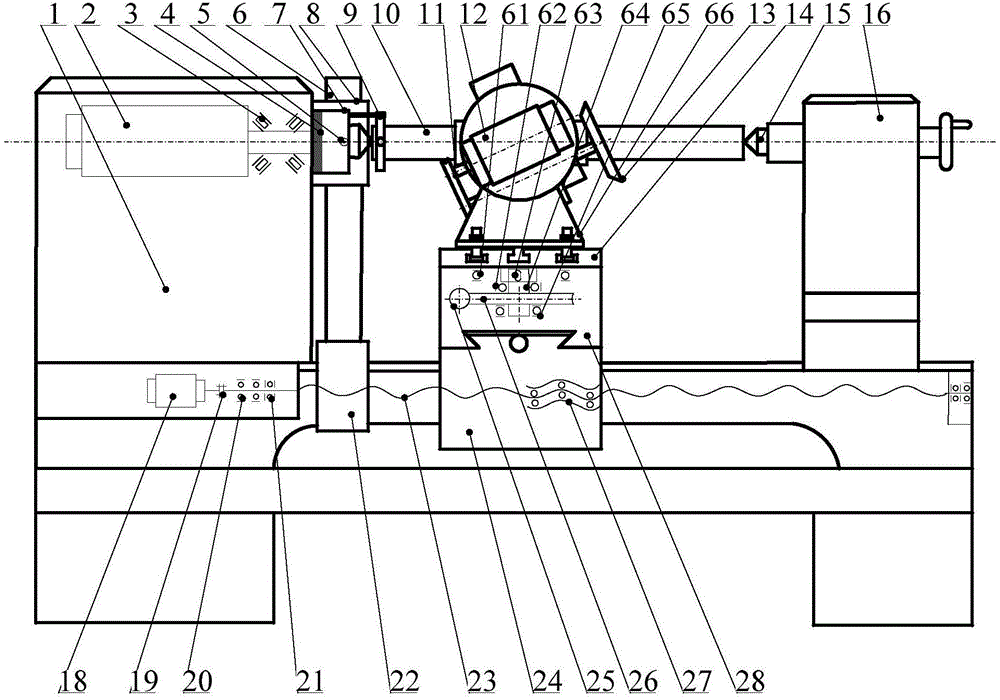

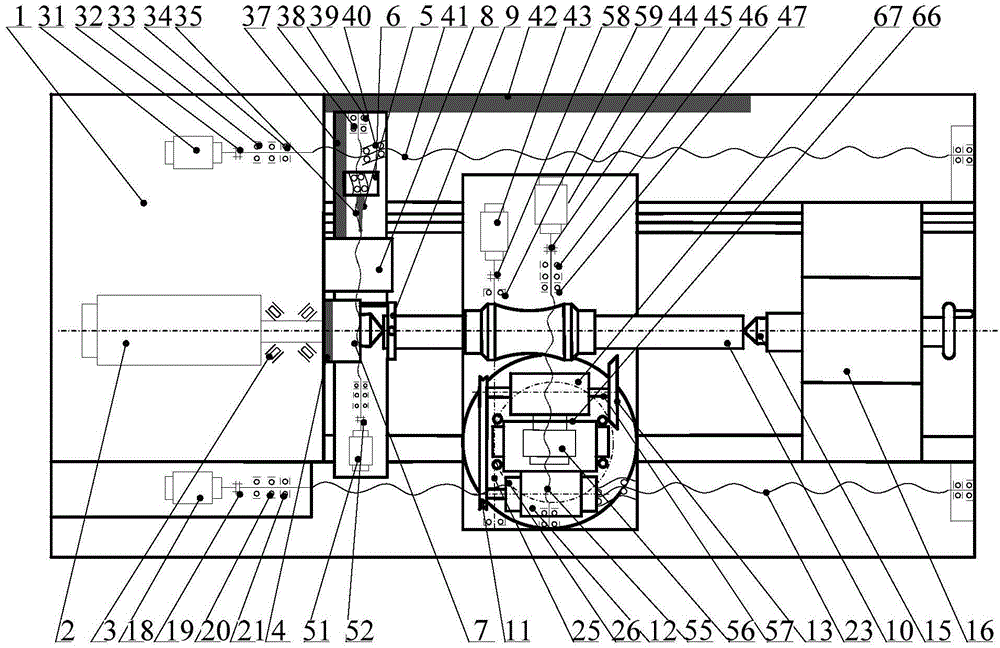

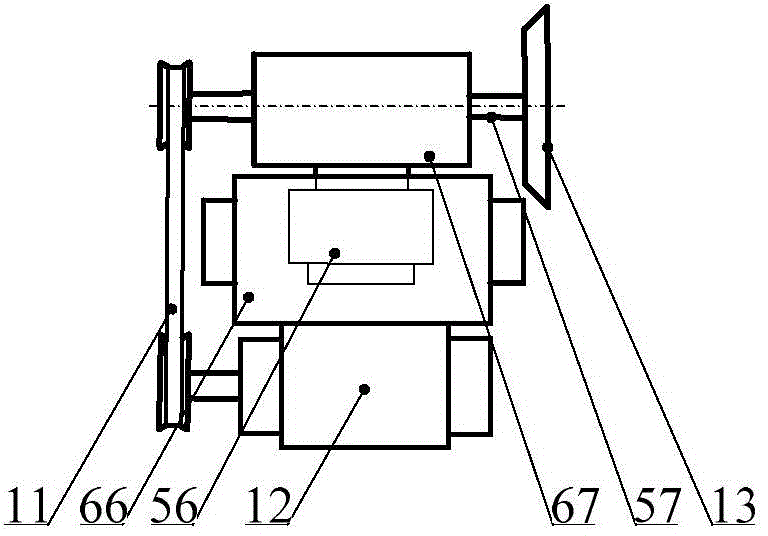

[0038] like Figures 6 to 9 As shown, an on-line detection and correction processing method for a torus worm tooth surface includes the following steps:

[0039] 1. According to the center distance of the plane enveloping toroidal worm 1, the transmission ratio, the radius of the main base circle, the inclination of the parent plane and the center of rotation O of the grinding head 2 The basic parameters such as the initial position coordinate value and the radius of the circular arc of rotation are determined by the following formula to determine the center of rotation O of the grinding head during the grinding process of the plane enveloping toroidal worm 10 2 The motion path arc ab and its grinding start point and grinding end point are obtained, and then the grinding process program and detection motion path program of the toroidal worm tooth surface are obtained.

[0040] The NC codes with grinding are:

[0041] G03 X#01 Z#02 A#03 B#04 R#05 (1)

[0042] In formula (1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com