A steam pipe steel-concrete combined base form for precast concrete

A technology for precast concrete and steam pipes, applied in the field of construction, can solve the problems of product quality decline, deformation of steel bottom formwork panels, and failure of steel bottom formwork to reach the service life, so as to reduce the usage amount, increase the service life, and improve the overall stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

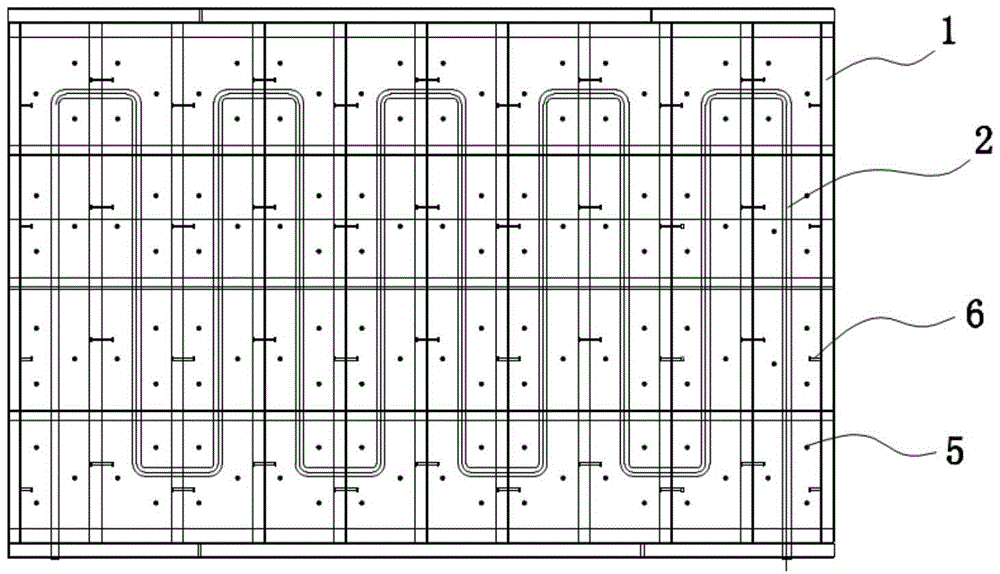

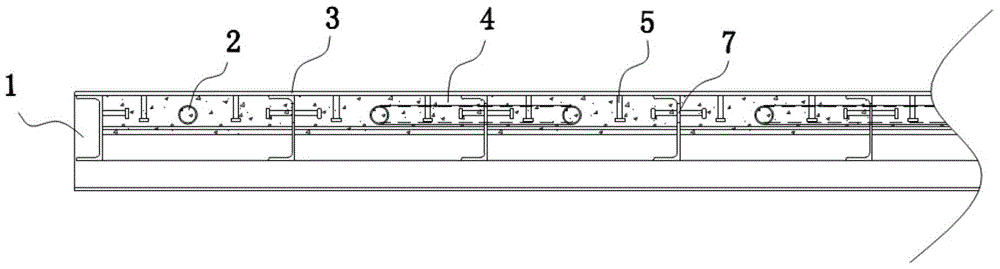

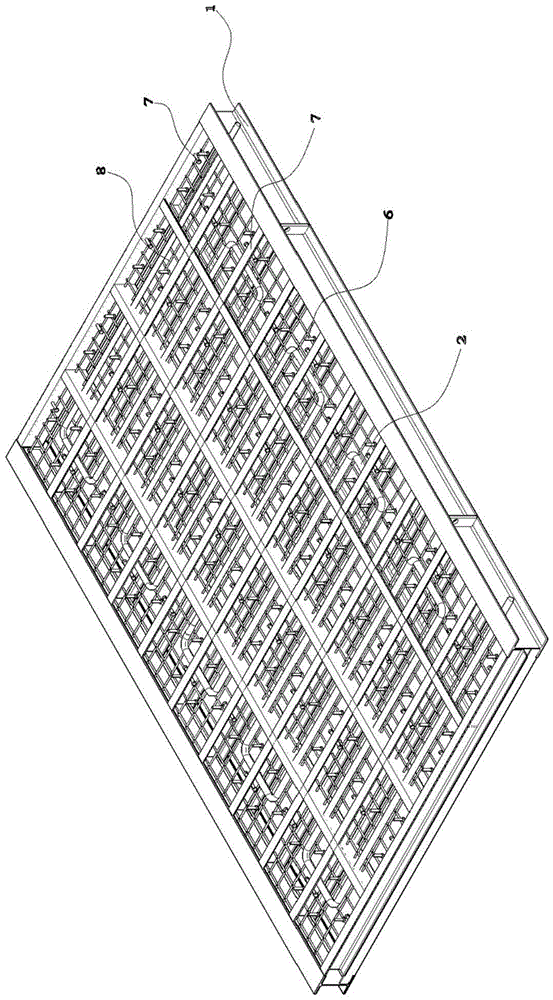

[0020] Such as Figure 1-3 As shown, the steam pipe steel-concrete combination bottom mold includes a three-dimensional bottom mold frame 1 and a steam pipe 2. The steam pipe is made of seamless steel pipes and U-shaped to ensure uniform heat transfer distribution; the three-dimensional bottom mold frame is made of steel plates (ie, the top plate 3), section steel, channel steel 7 etc. are combined to form, and the bottom mold frame of top plate 3 lower surfaces is provided with the grid frame layer that is formed by the combination of a plurality of channel steel 7, and steam pipe 2 passes through the hole provided on the channel steel 7 to The U-shaped surround is buried in the grid frame layer, the channel steel is provided with horizontal welding shear nails 6, and the grid frame layer is filled with concrete to form a concrete layer 4.

[0021] Further, the grid frame layer is provided with reinforcement mesh or wire mesh 8 filled in concrete.

[0022] During specific im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com