Demountable nonmetallic FRP electrostatic dust collection device suitable for automatic production

An electrostatic dust collection, non-metallic technology, applied in the field of detachable non-metallic FRP electrostatic dust collection device, can solve the problems of unsatisfactory dust collection effect, high basic cost of the box body, complicated processing technology, etc., and achieve light weight, high Dust absorption effect, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

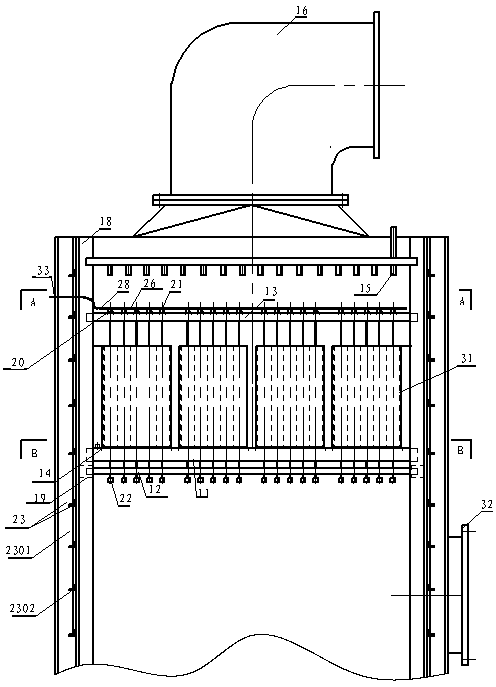

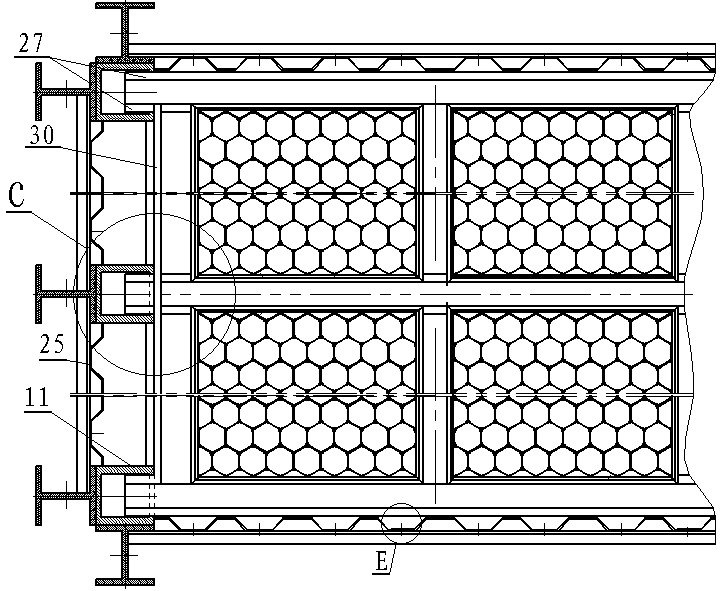

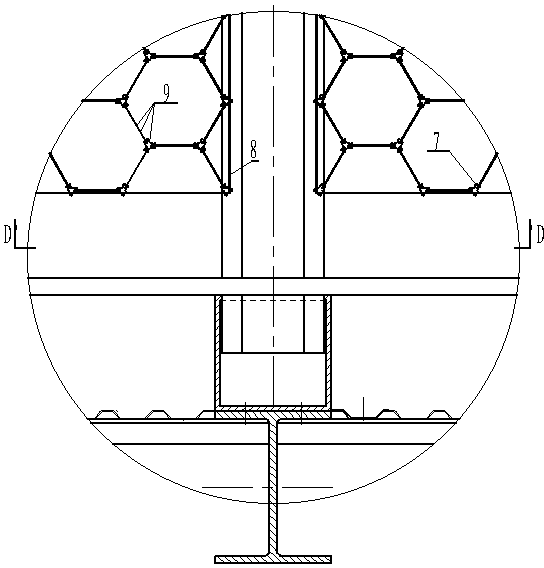

[0031] Such as Figure 1-Figure 5 As shown, the detachable non-metallic FRP electrostatic dust collector suitable for automatic production related to the present invention includes a box body composed of an FRP steel grid frame 23 and an FRP box plate 25 sealed and installed on the FRP steel grid frame 23. A water spray nozzle 15 and a chimney 16 are provided on the top of the box, a smoke inlet 32 is provided at the bottom of the box, and a plurality of pairs of FRP vertical beams 18 are fixed on both sides of the box, and FRP vertical beams 18 are located on both sides of the box. FRP beams 19 are arranged between each pair of upright beams 18. FRP cathode joists 13 and FRP anode support beams 11 are installed from top to bottom between each pair of vertical beams 18. On the cathode joists 131, a plurality of FRP beams are placed horizontally through FRP angle steel and high-strength plastic screws. The cathode top support tube 20, a plurality of FRP cathode bottom positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com