Sputtering target and process for manufacturing same

A manufacturing method and technology for sputtering targets, which are applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of difficulty in high density, achieve stable sputtering, improve yield, and reduce abnormal discharge the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

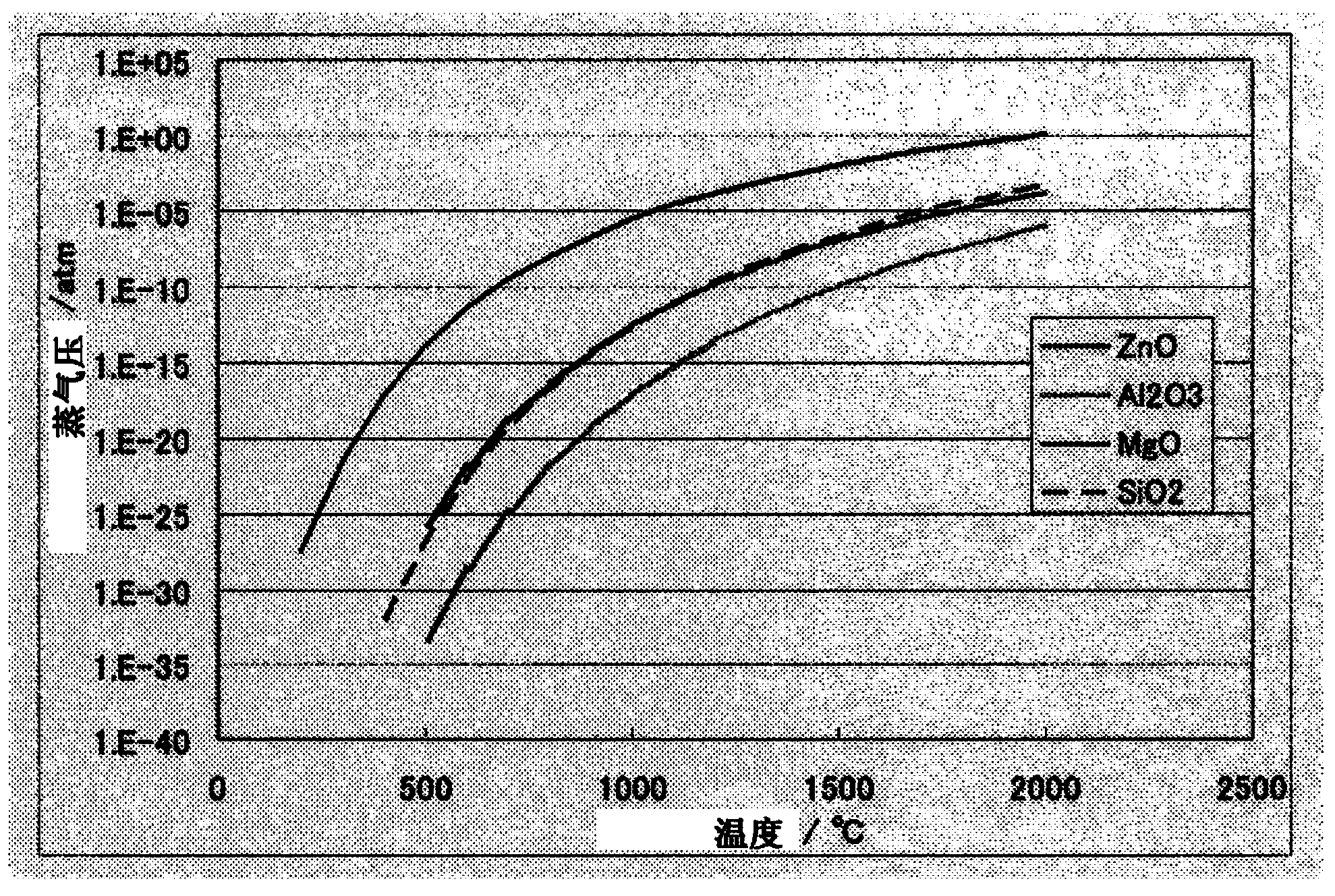

[0088] Prepare ZnO powder equivalent to 4N of 5 μm or less, MgO powder equivalent to 4N with an average particle diameter of 5 μm or less, and Al equivalent to 4N with an average particle diameter of 5 μm or less. 2 o 3 Powder, SiO equivalent to 4N with an average particle size of 5 μm or less 2 Powder, B equivalent to 4N with an average particle size of 5 μm or less 2 o 3 pink.

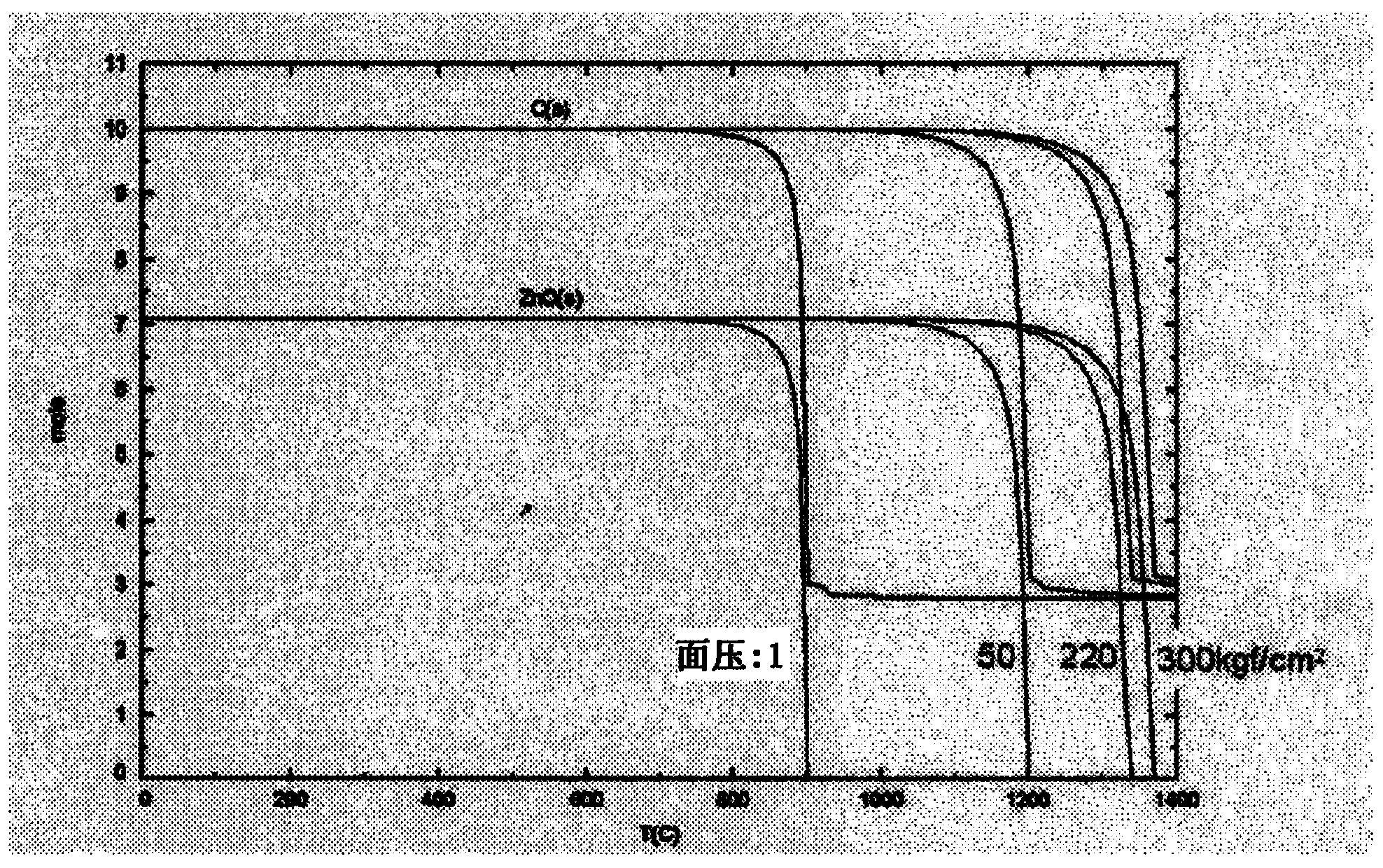

[0089] Next, these powders were prepared into the compounding ratio shown in Table 2, and after mixing, hot pressing (HP) was performed at the temperature of 1050 degreeC. The pressure of hot pressing is set to 220kg / cm 2 .

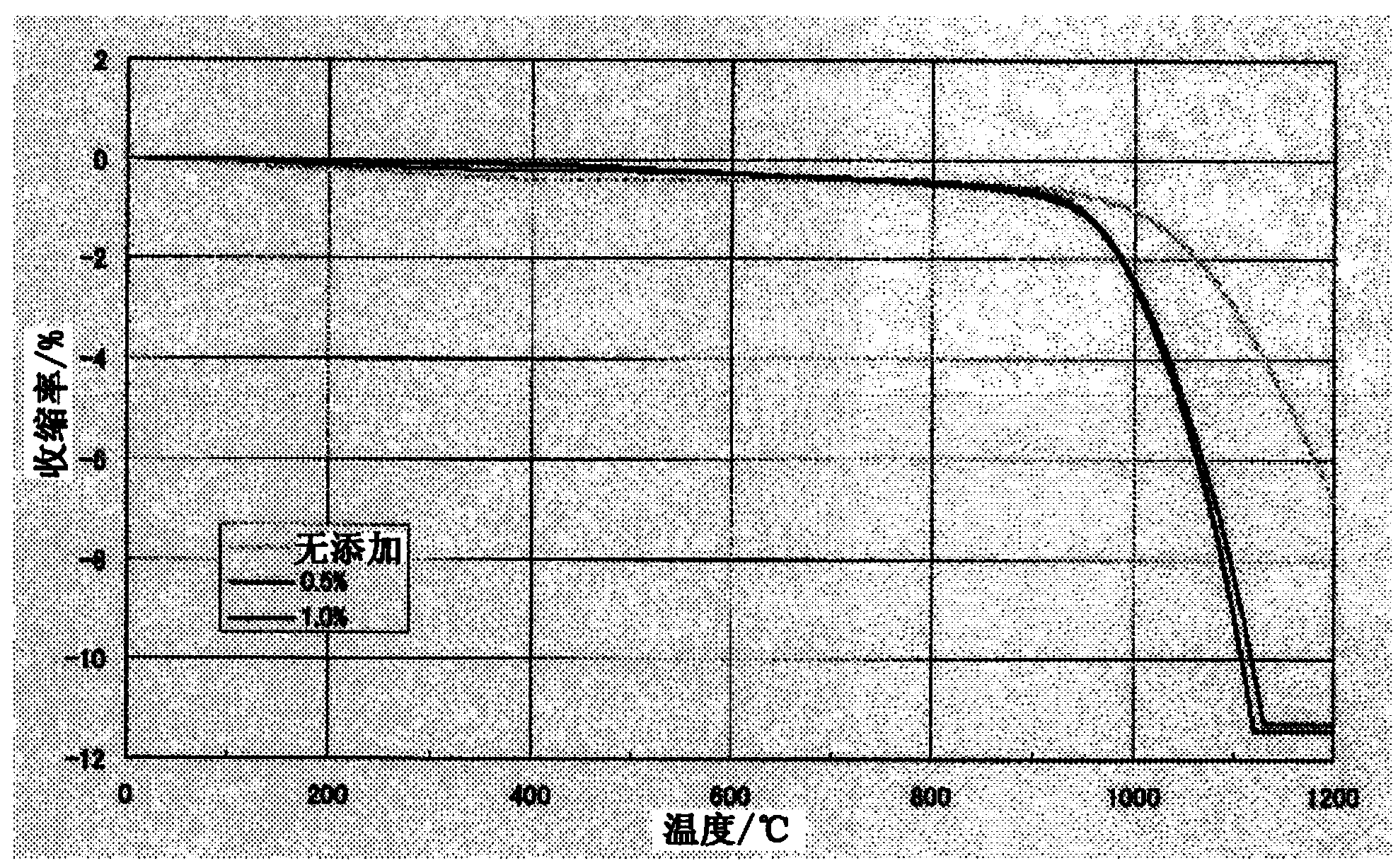

[0090] As shown in Table 2, the ratio of raw materials is set to ZnO powder: 72.0 mol%, MgO powder: 24.6 mol%, Al 2 o 3 Powder: 1.2 mol%, SiO 2 Powder: 2.2 mol%, the total is 100 mol%, and it is made into a basic raw material. Then, further fit B into it 2 o 3 Powder: 1.0% by weight, made into sintered raw material. After sintering, the sintered body is finished into...

Embodiment 2

[0103] Prepare ZnO powder equivalent to 4N of 5 μm or less, MgO powder equivalent to 4N with an average particle diameter of 5 μm or less, and Al equivalent to 4N with an average particle diameter of 5 μm or less. 2 o 3 Powder, SiO equivalent to 4N with an average particle size of 5 μm or less 2 Powder, B equivalent to 4N with an average particle size of 5 μm or less 2 o 3 pink.

[0104] Next, these powders were prepared into the compounding ratio shown in Table 2, and after mixing, hot pressing (HP) was performed at the temperature of 1050 degreeC. The pressure of hot pressing is set to 220kg / cm 2 .

[0105] As shown in Table 2, the ratio of raw materials is set as ZnO powder: 72.0 mol%, MgO powder: 24.6 mol%, Al 2 o 3 Powder: 1.2 mol%, SiO 2 Powder: 2.2 mol%, the total is 100 mol%, and it is made into a basic raw material. Then, further fit B into it 2 o 3 Powder: 0.5% by weight, made into sintered raw material.

[0106] B 2 o 3 The proportioning of powder is l...

Embodiment 3

[0109] Prepare ZnO powder equivalent to 4N of 5 μm or less, MgO powder equivalent to 4N with an average particle diameter of 5 μm or less, and Al equivalent to 4N with an average particle diameter of 5 μm or less. 2 o 3 Powder, SiO equivalent to 4N with an average particle size of 5 μm or less 2 Powder, B equivalent to 4N with an average particle size of 5 μm or less 2 o 3 pink.

[0110] Next, these powders were prepared into the compounding ratio shown in Table 2, and after mixing, hot pressing (HP) was performed at the temperature of 1050 degreeC. The pressure of hot pressing is set to 220kg / cm 2 .

[0111] As shown in Table 2, the ratio of raw materials is set as ZnO powder: 89.3 mol%, MgO powder: 9.2 mol%, Al 2 o 3 Powder: 0.7 mol%, SiO 2 Powder: 0.8 mol%, the total is 100 mol%, and it is made into a basic raw material. Then, further fit B into it 2 o 3 Powder: 1.0% by weight, made into sintered raw material. B 2 o 3 The proportioning of powder is identical w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com