High-voltage composite insulator

A technology for composite insulators and insulators, applied in the direction of insulators, ceramic layered products, coatings, etc., can solve the problems of rapid loss of anti-fouling ability and insufficient anti-icing ability, and achieve the goal of reducing icing accidents and pollution flashover Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

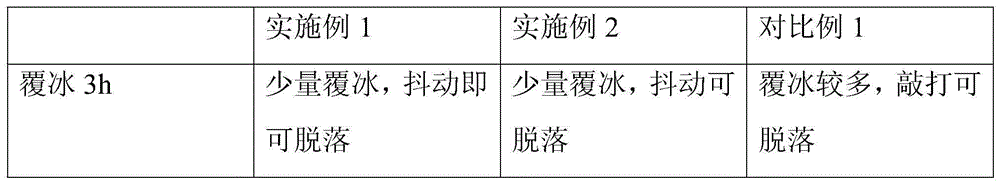

Examples

Embodiment 1

[0024] BaCO 3 、TiO 2 , La 2 o 3 , Y 2 o 3 , SrO was pulverized by wet ball mill according to the molar ratio of 0.9:1:0.02:0.01:0.02, dehydrated and dried, preheated at 300°C for 1h, and calcined at 1200°C for 2h to obtain modified BaTiO 3 material, the modified BaTiO 3 The material is placed on the cathode of the vacuum coating equipment as the sputtering target, and the fired insulator body is used as the anode to obtain modified BaTiO 3 material coated insulators.

[0025] Mix nano-titanium dioxide, polytetrafluoroethylene nano-powder, and ethyl acetate uniformly in a mass ratio of 15:10:30 to obtain a photocatalytic nano-coating; cool the insulator below 50°C; apply the photocatalytic nano-coating, and then follow At a heating rate of 20 °C / min, the temperature was raised to 600 °C and maintained for 3 hours, and then dropped to room temperature at a cooling rate of 20 °C / min. A high-voltage composite insulator can be obtained.

Embodiment 2

[0027] BaCO 3 、TiO 2 , La 2 o 3 , Y 2 o 3 , SrO was pulverized by wet ball mill according to the molar ratio of 0.9:1:0.02:0.01:0.02, dehydrated and dried, preheated at 300°C for 1h, and calcined at 1200°C for 2h to obtain modified BaTiO 3 material, the modified BaTiO 3 The material was pulverized and sieved several times in a ball mill to obtain 600-mesh modified BaTiO 3 Material. Mix the modified BaTiO3 material powder with ethyl acetate, sodium silicate, and absolute ethanol in a mass ratio of 20:50:20:80, stir, and ultrasonically disperse for 3 hours to obtain the modified BaTiO3 3 Material coating, coating the coating on the surface of the insulator, and calcining at 500°C for 1h.

[0028] Mix nano-titanium dioxide, polytetrafluoroethylene nano-powder, and ethyl acetate uniformly in a mass ratio of 15:10:30 to obtain a photocatalytic nano-coating; cool the insulator below 50°C; apply the photocatalytic nano-coating, and then follow At a heating rate of 20 °C / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com