Air-conditioner defrosting method

A technology for air conditioning and defrosting temperature, applied in the field of air conditioning defrosting, can solve the problems of low suction pressure of compressor, reduced heating comfort and system energy efficiency, insufficient defrosting energy source, etc., and achieve the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

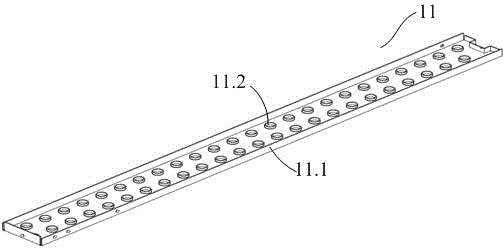

[0024] refer to figure 1 and figure 2 In this embodiment, the method for defrosting an air conditioner by using ultrasonic waves, the outdoor unit of the air conditioner includes a heat exchanger 1 , an outdoor fan 2 installed on the heat exchanger 1 , and an ultrasonic transducer 3 . Specifically, an ultrasonic energy transfer plate 11 is installed on the heat exchanger 1, holes are opened on the ultrasonic energy transfer plate 11, and the number of holes is consistent with the number of holes in the fins of the heat exchanger. process, that is, the expansion tube process is fixed on the copper tube of the heat exchanger, which can be arranged parallel to the fins. The ultrasonic energy transmission plate 11 has a side flange 11.1, and the ultrasonic transducer 3 is installed on its side wall flange 11.1. . The installation of the ultrasonic energy transmission plate 11 does not require additional processing procedures, and has a large contact area with the copper tube, w...

Embodiment 2

[0037] like figure 2 As shown, the difference from Embodiment 1 is that in step d of this embodiment, a pneumatic device is installed on the outdoor unit to blow off floating frost. Specifically, the pneumatic device includes an air pump 4 , an air collecting pipe 5 and a nozzle 6 arranged on the air collecting pipe 5 . When the frost layer is vibrated by the ultrasonic transducer 3 to become floating frost, the pneumatic device is activated, and the air flows through the air collecting pipe 5 and nozzle 6 to the heat exchanger 1 to automatically blow off the floating frost.

[0038] Similarly, in the step e, the time for the ultrasonic transducer 3 to stop running can be the same time as the closing time of the pneumatic device, or it can be earlier than the closing time of the pneumatic device, so that the pneumatic device can blow off the floating device more fully and thoroughly. Frost.

[0039] In order to improve the blow-off speed and the uniformity of the airflow, i...

Embodiment 3

[0042] like image 3 As shown, the difference from Embodiment 1 or 2 is that in step d of this embodiment, a mechanical brush is provided on the heat exchanger 1 to sweep off floating frost. Specifically, the mechanical sweeping brush includes a slideway 7 vertically fixed on the heat exchanger 1, a sweeping brush 8 that slides with the slideway 7 at both ends, a ferromagnetic block 9 fixed on the sweeping brush 8 and a fixed On the excitation coil 10 on the upper part of the heat exchanger 1 , the bristles of the sweeping brush 8 contact the fins of the heat exchanger 1 . When the mechanical sweeping brush is in the non-working state, the sweeping brush 8 is in the lower part of the heat exchanger 1 under the action of its own gravity. When the mechanical sweeping brush needs to work, the excitation coil 10 is energized to generate magnetism, and the ferromagnetic block 9 is attracted. Then pull the sweeping brush 8 to move upwards, sweep the fins, and finally reach the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com