Polycrystalline silicon battery chip corrosion solution and preparation process thereof

A technology of polysilicon battery and corrosion solution, which is applied in the directions of crystal growth, post-processing details, and post-processing, etc. It can solve problems such as difficulties in large-scale production, difficult control of product quality repeatability, and increased process costs. The effect of clean surface, uniform and slow reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: A preparation process of polycrystalline silicon cell corrosion solution, including the following steps, the component ratio is counted in parts by weight: inject 66 parts of water into the texturing tank and cool down to 12°C, add 10 parts of hydrofluoric acid, 80 1 part nitric acid and 1 part texturizing auxiliary agent; pass nitrogen gas into bubbles, and at the same time cool down with refrigerated water circulation to ensure that the temperature is at 5°C to obtain the corrosive liquid; wherein, the flow rate of nitrogen gas is 5L / min, and the temperature of circulating refrigerated water is 0°C.

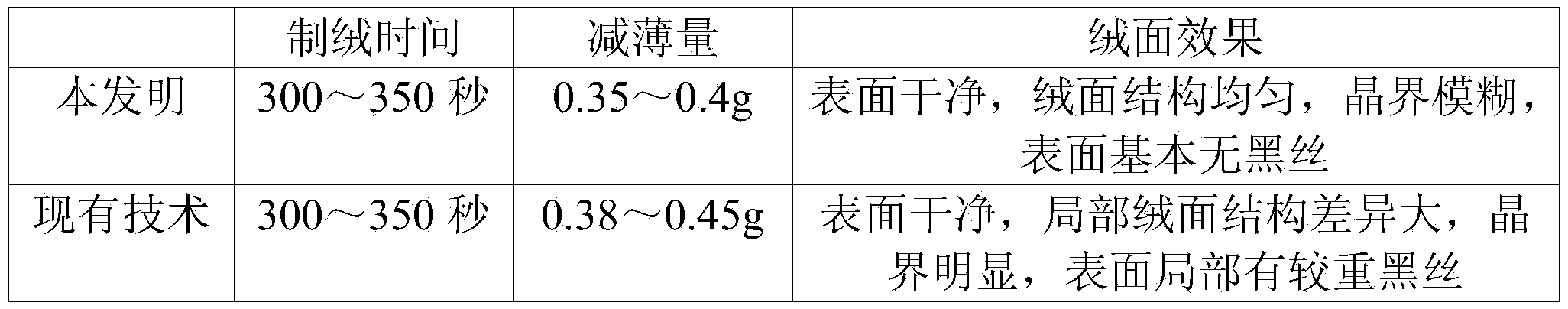

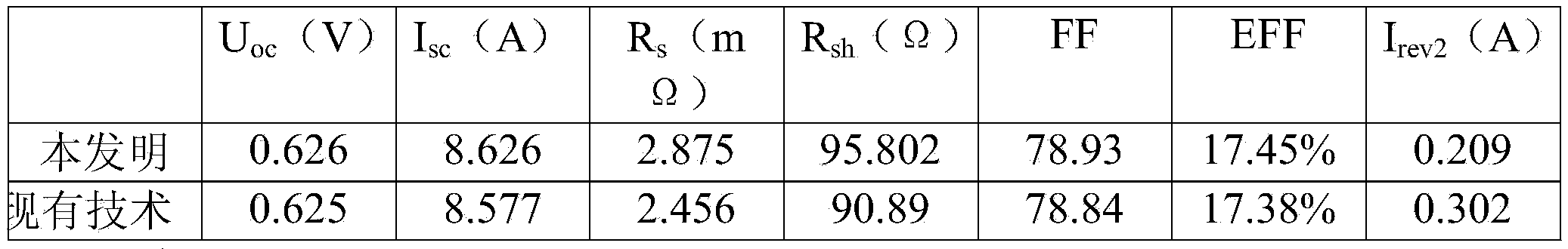

[0011] When using the obtained etching note, take 200 pieces of P-type doped polysilicon wafers with a size of 156cm×156cm and a thickness of 200±20μm, weigh them with a balance, put them into the prepared etching solution, and react in 350 seconds. The best surface effect, the surface is clean, the grain boundaries are fuzzy, basically no black silk spots,...

Embodiment 2

[0012] Embodiment 2: A preparation process of polycrystalline silicon cell corrosion solution, including the following steps, the component ratio is counted in parts by weight: inject 66 parts of water into the texturing tank and cool it down to 15°C, add 12 parts of hydrofluoric acid, 82 1 part nitric acid and 3 parts of texturizing auxiliary agent; pass into nitrogen bubble, at the same time cool down with refrigerated water circulation, ensure that the temperature is at 8 ℃, obtain described corrosive liquid; Wherein, nitrogen gas flow rate is 15L / min, and the temperature of circulating refrigerated water is 4°C.

[0013] When using the obtained etching note, 200 pieces of P-type doped polysilicon wafers with a size of 156cm×156cm and a thickness of 200±20μm were weighed with a balance, and then put into the prepared etching solution for reaction. It took 340 seconds to reach The best surface effect, the surface is clean, the grain boundaries are fuzzy, basically no black s...

Embodiment 3

[0014] Embodiment 3: A preparation process of polycrystalline silicon cell corrosion solution, including the following steps, the component ratio is counted in parts by weight: inject 66 parts of water into the texturing tank and cool down to 13 ° C, add 11 parts of hydrofluoric acid, 81 1 part nitric acid and 2 parts texturizing auxiliary agent; pass into nitrogen bubbles, and at the same time cool down with refrigerated water circulation, guarantee the temperature at 6 ℃, obtain described corrosive liquid; Wherein, nitrogen gas flow rate is 10L / min, and the temperature of circulating refrigerated water is 2°C.

[0015] When using the obtained etching note, take 200 pieces of P-type doped polysilicon wafers with a size of 156cm×156cm and a thickness of 200±20μm, weigh them with a balance, put them into the prepared etching solution, and react in 330 seconds. The best surface effect, the surface is clean, the grain boundaries are fuzzy, basically no black silk spots, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com