Preparation method of titanium oxide nanotube array-silver composite coating material

A technology of titanium oxide nanotubes and composite coatings, applied in coatings, electrolytic coatings, nanotechnology, etc., can solve problems such as uneven antibacterial properties, achieve uniform biological activity, stabilize antibacterial properties, and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the titanium oxide nanotube array-silver composite coating material of the present embodiment comprises the following steps:

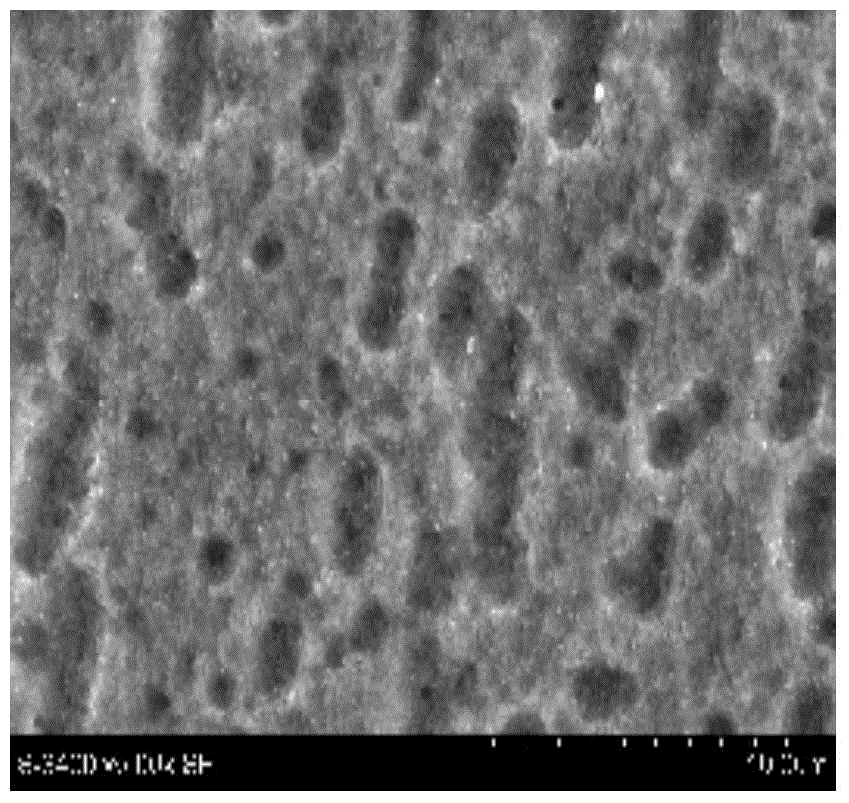

[0028] (1) Preparation of titanium oxide nanotube arrays: using pure titanium as the substrate, the surface is polished by metallographic sandpaper, cleaned and dried as the anode, the spectrally pure graphite sheet is used as the cathode, and 0.5wt% HF solution is used as the electrolyte. After anodizing at 10V for 20 minutes, take it out, wash it with distilled water, and dry it at 100°C for later use;

[0029] (2)AgNO 3 Preparation of soaking solution: Weigh 2.2g of silver nitrate and dissolve it in 10mL of distilled water to obtain AgNO 3 Soaking solution;

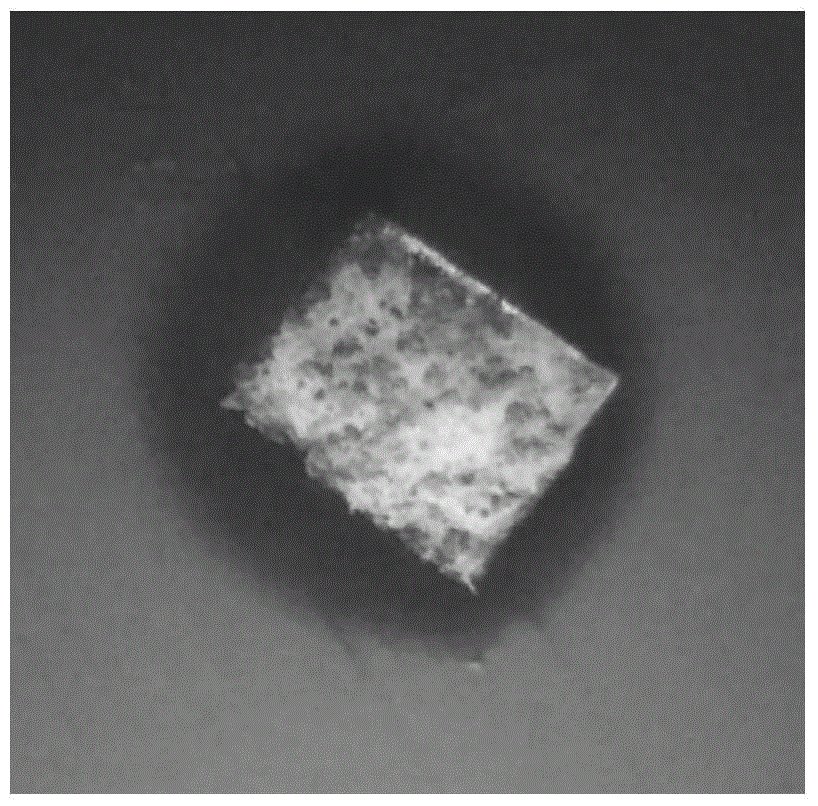

[0030] (3) Soaking: Under the condition of avoiding light, soak the titanium oxide nanotube array dried in step (1) in AgNO 3 5 minutes in the soaking solution;

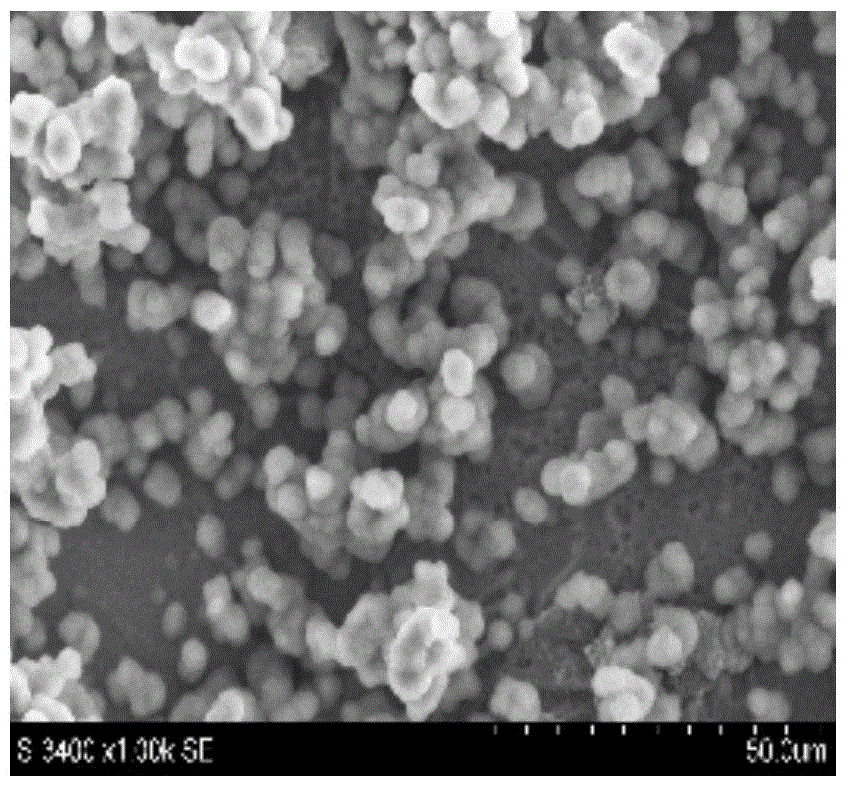

[0031] (4) Heat treatment: wash the surface of the titanium oxide nanotube array soaked in step...

Embodiment 2

[0034] The preparation method of the titanium oxide nanotube array-silver composite coating material of the present embodiment comprises the following steps:

[0035] (1) Preparation of titanium oxide nanotube arrays: using pure titanium as the substrate, the surface is polished with metallographic sandpaper, cleaned and dried as the anode, the spectrally pure graphite sheet is used as the cathode, and 0.4wt% HF solution is used as the electrolyte. After anodizing at 20V for 20 minutes, take it out, wash it with distilled water, and dry it at 80°C for later use;

[0036] (2)AgNO 3 Preparation of soaking solution: Weigh 22g of silver nitrate and dissolve in 10mL of distilled water to obtain AgNO 3 Soaking solution;

[0037] (3) Soaking: Under the condition of avoiding light, soak the titanium oxide nanotube array dried in step (1) in AgNO 3 8 minutes in the soaking solution;

[0038] (4) Heat treatment: Clean the surface of the titanium oxide nanotube array soaked in step (...

Embodiment 3

[0041] The preparation method of the titanium oxide nanotube array-silver composite coating material of the present embodiment comprises the following steps:

[0042] (1) Preparation of titanium oxide nanotube arrays: using pure titanium as a substrate, the surface is polished with metallographic sandpaper, cleaned, and dried as an anode, with a spectrally pure graphite sheet as a cathode, and 0.1wt% HF solution as an electrolyte. After anodizing at 30V for 40 minutes, take it out, wash it with distilled water, and dry it at 100°C for later use;

[0043] (2)AgNO 3 Preparation of soaking solution: Weigh 10g of silver nitrate and dissolve in 10mL of distilled water to obtain AgNO 3 Soaking solution;

[0044] (3) Soaking: Under the condition of avoiding light, soak the titanium oxide nanotube array dried in step (1) in AgNO 3 10min in soaking solution;

[0045] (4) Heat treatment: wash the surface of the titanium oxide nanotube array soaked in step (3) with distilled water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com