Ethanol fermentation and separation system using solar energy to heat

A technology for ethanol fermentation and separation system, which is applied in specific-purpose bioreactor/fermenter, separation/purification of hydroxyl compounds, bioreactor/fermenter combination, etc., can solve the problem of increasing distillation difficulty, energy consumption, ethanol concentration Low, difficult to deal with, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

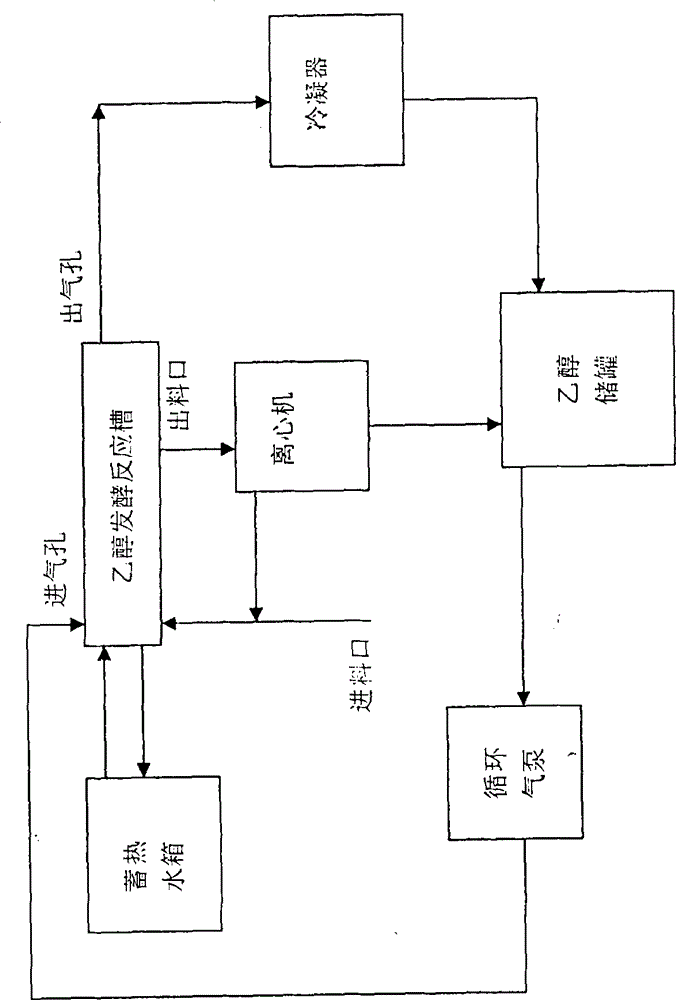

[0008] Below in conjunction with accompanying drawing, the present invention will be further described;

[0009] The system of the invention comprises an ethanol fermentation reaction tank, a heat storage tank, a condenser, an ethanol storage tank, a centrifuge and a circulating air pump. The ethanol fermentation reaction tank is rectangular, with a bottom area of 30 square meters and a height of 1 meter. The sugar solution with a volume of 15 cubic meters and a mass fraction of 10% is injected into the ethanol fermentation reaction tank to ensure that the air inlet and the air outlet are all above the liquid surface of the sugar solution, and the liquid yeast with a volume of 0.5 cubic meters is added to carry out the fermentation reaction. Solar collector panels collect solar energy and store heat in a 5 cubic meter hot water storage tank. The heat storage tank maintains the temperature of the ethanol fermentation reaction tank at 35°C through indirect heating of the coil...

Embodiment 2

[0011] The ethanol fermentation reaction tank is cylindrical, with a bottom area of 20 square meters and a height of 2 meters. A volume of 20 cubic meters of sugar solution with a mass fraction of 20% is poured into the ethanol fermentation reaction tank to ensure that the air inlet and the air outlet are all above the liquid surface of the sugar solution, and a volume of 1 cubic meter of liquid yeast is added to carry out the fermentation reaction. Solar collector panels collect solar energy and store heat in a 5 cubic meter hot water storage tank. The heat storage tank maintains the temperature of the ethanol fermentation reaction tank at 35°C through indirect heating of the coil. The flow rate of the circulating air pump is 6 cubic meters per minute, and the ethanol gas volatilized in the fermentation broth is quickly taken away from the ethanol fermentation reaction tank. The ethanol gas taken away is condensed into liquid through the condenser and enters the ethanol sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com