Biomass environment-friendly water-based color paste and preparation method thereof

A water-based color paste, biomass technology, applied in the direction of pigment paste, etc., can solve the problems of poor storage stability, low degree of color retention, single function, etc., to reduce surface tension, prevent agglomeration, and increase film formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

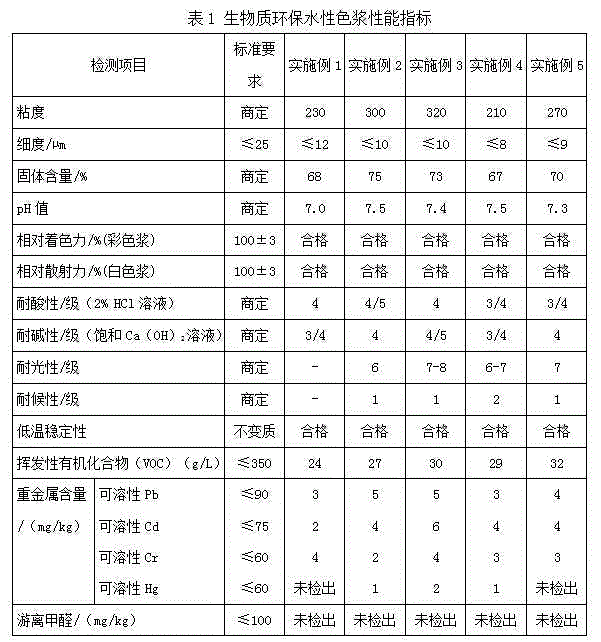

Examples

preparation example Construction

[0028] 3. The preparation process of acid hydrolyzed hydroxypropyl starch is as follows: in deionized water, add a swelling inhibitor relative to the starch mass ratio of 13%, add sodium hydroxide accounting for 1.0% of the starch mass, mix and stir until dissolved, and add the step (1) Adjust the prepared acid-thinned starch into 35% starch milk, stir and alkalinize for 40 minutes, heat up to 42°C, add propylene oxide accounting for 5% of the starch mass, etherify for 14 hours, add 10% hydrochloric acid to adjust the pH to 7.0, after centrifugal dehydration, drying and sieving, the acid hydrolyzed hydroxypropyl starch can be obtained;

[0029] 4. The preparation process of acid-thinned starch used in the preparation process of acid-thinned carboxymethyl starch and acid-thinned hydroxypropyl starch is as follows: add HCl solution with a mass percentage concentration of 0.6% to the starch, and prepare starch with a concentration of 38%. Milk, heated to 50°C, acidolysis for 2 ho...

Embodiment 1

[0035] Example 1: Biomass environmentally friendly water-based color paste (white)

[0036] Titanium dioxide 40kg, biomass stabilizer carboxymethyl starch 5 kg, compound modified starch emulsion 22kg, aluminum starch dodecenyl succinate 1kg, dispersant OROTAN731A polycarboxylate sodium salt 15 kg, defoamer fatty acid metal soap 0.4 kg, 0.2 kg of sodium hydroxide as a pH regulator, 3 kg of polyethylene glycol as a wetting agent, and 13.4 kg of demineralized water.

[0037] 2. Preparation of water-based color paste

[0038] a) Add titanium dioxide to the disperser according to the stated ratio, adjust the speed of the disperser to 600r / min, and sequentially add demineralized water, composite modified starch emulsion, dispersant, biomass stabilizer, wetting agent, dodecenyl Add starch aluminum succinate and pH regulator to the dispersing tank, disperse for 25 minutes to obtain a uniform slurry, increase the dispersing speed to 1500r / min, and disperse for 20 minutes.

[0039] b...

Embodiment 2

[0050] Example 2. Biomass environmentally friendly water-based color paste (black)

[0051] 40 kg of carbon black, 3 kg of biomass stabilizer hydroxypropyl starch, 25 kg of compound modified starch emulsion, 2 kg of aluminum starch dodecenyl succinate, 10 kg of high-efficiency dispersant SN-5040 polycarboxylate sodium salt, Defoamer organic phosphate 0.2 kg, pH regulator sodium bicarbonate 0.3 kg, wetting agent polypropylene glycol 2 kg, demineralized water 5 kg.

[0052] 2. Preparation of water-based color paste

[0053] a) Add carbon black to the disperser according to the stated ratio, adjust the speed of the disperser to 500r / min, and sequentially add demineralized water, composite modified starch emulsion, dispersant, biomass stabilizer, wetting agent, dodecene according to the stated ratio Starch aluminum succinate and pH regulator were added to the dispersing cylinder for 30 minutes to disperse to obtain a uniform slurry. Increase the dispersing speed to 1500r / min and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com