A Rapid Measurement Method of Rail Stiffness Based on Rail Deformation Velocity

A technology of deformation speed and measurement method, which is applied in the direction of railway vehicle shape measuring device, railway car body parts, railway auxiliary equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the principle of the present invention will be firstly described below.

[0029] 1. The establishment of rail deformation deflection curve model.

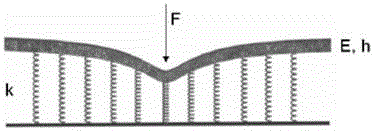

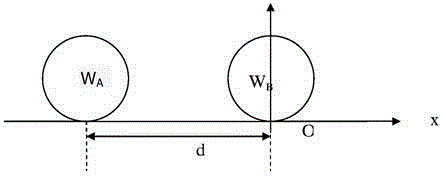

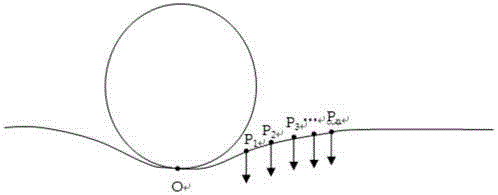

[0030] Assume that the rail is an infinitely long beam on an elastic foundation, such as figure 2 As shown, according to the Euler-Bernoulli beam theory and the Winkler foundation model, the deflection curve differential equation of the rail deformation curve can be deduced, as shown in Equation 1, where F is the normal pressure at this point, E is the rail rigidity, and I is the moment of inertia of the rail, k is the elastic coefficient, x is the horizontal distance from the load center, and y is the deflection.

[0031] EI d 4 dx 4 y ( x ) + ky ( x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com