Preparing method of anti-dazzle glass

A technology of anti-glare glass and aluminosilicate glass, which is applied in the field of preparation of anti-glare glass and can solve problems such as complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of anti-glare glass, comprising the following steps:

[0032] Step S110, removing dirt on the surface of the aluminosilicate glass.

[0033] The aluminosilicate glass contains silicon dioxide, aluminum oxide and an alkali metal oxide, and the alkali metal oxide is at least one selected from sodium oxide and potassium oxide.

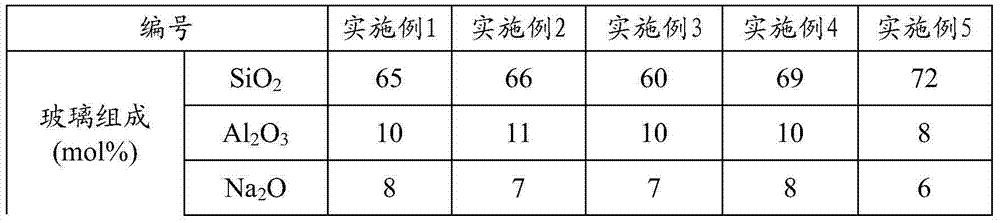

[0034] Further, the aluminosilicate glass includes the following components in terms of molar percentage:

[0035] 60%~75% silicon dioxide, 5%~10% aluminum oxide, 5%~8% sodium oxide, 0%~3% potassium oxide, 1%~5% calcium oxide, 1%~ 5% magnesium oxide, 2%-5% boron trioxide and 0%-4% zirconium dioxide.

[0036] Silicon dioxide (SiO 2 ) is a necessary component to form aluminosilicate glass, and can improve the strength and chemical stability of aluminosilicate glass, but when its content is too high, aluminosilicate glass is difficult to melt, so its content is selected as 60 %~75%.

[0037] Aluminum oxide (Al 2 o 3 ) can i...

Embodiment 1~5

[0097] The preparation method of the antiglare glass of embodiment 1~5 is as follows:

[0098] To provide aluminosilicate glass, first use a disc brush with detergent to clean the aluminosilicate glass to remove the dirt on the surface of the aluminosilicate glass, and then use a disc brush with cerium oxide polishing powder to polish, the polished aluminosilicate The surface flatness of the glass is at least 0.01mm. After polishing, use a roller brush with deionized water to clean the aluminosilicate glass and dry it; preheat the aluminosilicate glass; then use a spray gun to spray the crystallization treatment agent on the aluminum The surface of the silicate glass is ion-exchanged to obtain anti-glare glass, the crystallization treatment agent on the glass surface is removed and the surface of the anti-glare glass is cleaned.

[0099] The spray gun used is the spray gun described in step S150 in the preparation method of the anti-glare glass.

[0100]Among them, the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com