Novel conveying belt

A conveyor belt, a new type of technology, applied in the field of new conveyor belts, can solve the problems of poor wear resistance, heavy conveyor belt, easy deformation, etc., to achieve excellent wear performance, overcoming poor high temperature resistance, small elongation deformation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

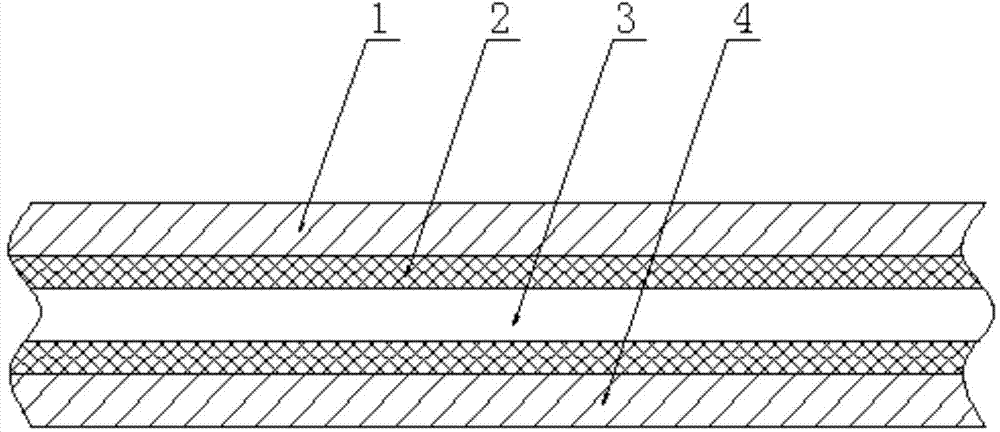

[0012] A new conveyor belt is composed of an upper cover rubber layer 1, a lower cover rubber layer 4, a fabric layer 2, and a middle rubber layer 3. The upper and lower cover rubber layers are alternately compounded with multiple layers of fabric layers and middle rubber layers.

[0013] Moreover, the upper and lower cover rubber layers and the middle rubber layer are made of EPDM rubber or chlorinated butyl rubber with good high temperature resistance, and are refined by compound molding and vulcanization with high temperature resistant materials. The fabric layer is made of polyester canvas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com