Photochromic azobenzene polyester, preparation method thereof and photochromic polyester fibers

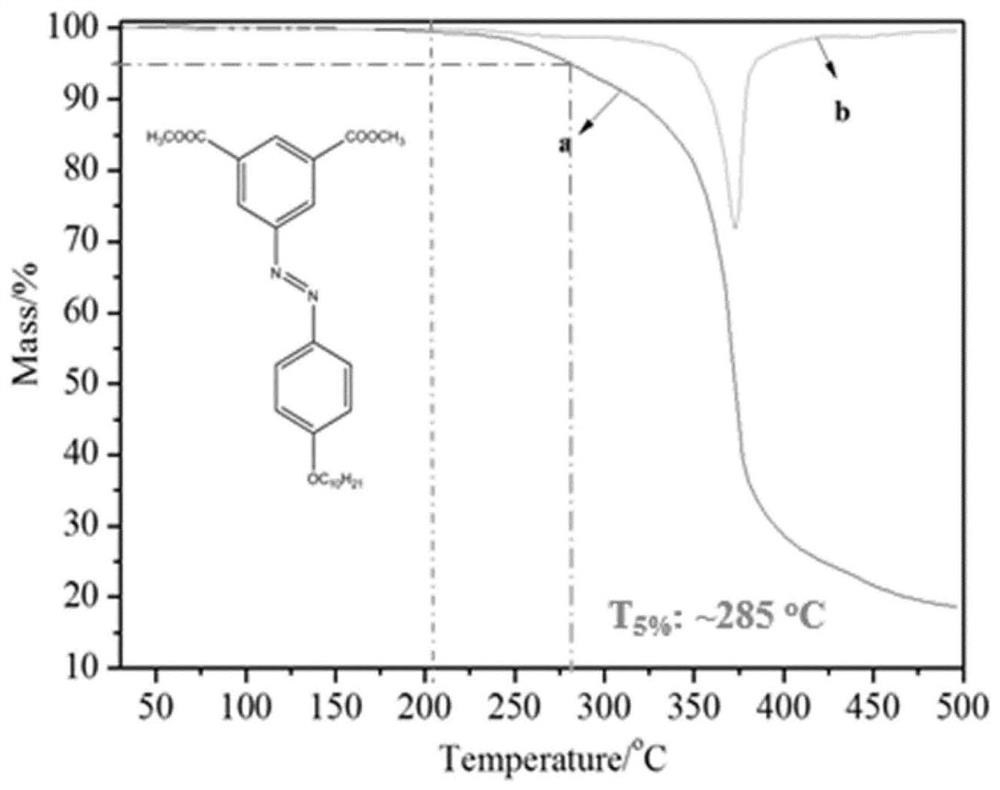

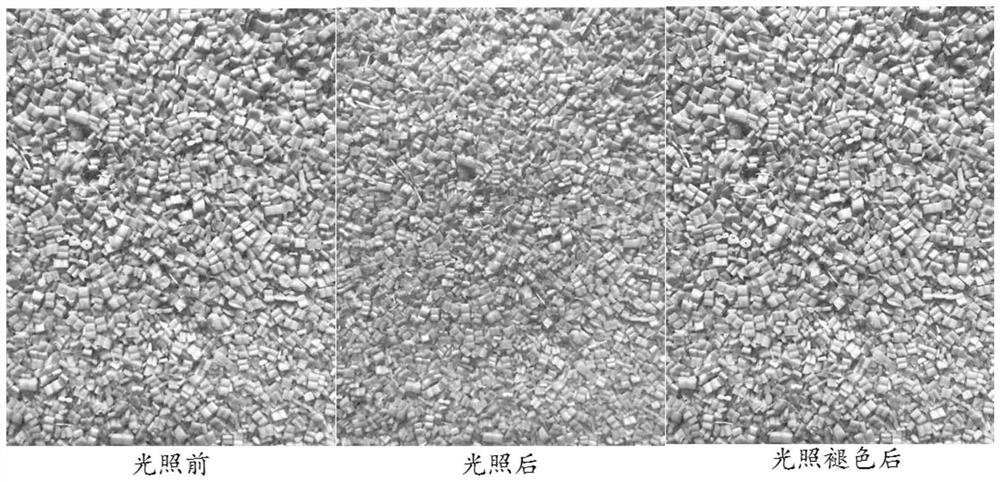

A technology of azobenzene polyester and photosensitive discoloration, which is applied in the direction of single-component copolyester artificial filaments, etc., can solve the problems of easy decomposition and failure to achieve photochromic effect, and improve high temperature resistance and discoloration sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A preparation method of the above-mentioned photosensitive color-changing azobenzene polyester, comprising the following steps:

[0055] S1. Put the suspension of dimethyl 5-aminoisophthalate in dilute hydrochloric acid solution, cool the solution in a water-ice bath at 0-5°C, add aqueous nitrite solution to it under stirring conditions, and stir Obtain diazonium salt suspension;

[0056] Then add it into a solution composed of sodium hydroxide and phenol or 1-naphthol, stir and react at 5°C for 20-40 minutes; then add it into an acidic aqueous solution to obtain a reddish-orange azo compound precipitate;

[0057] Then filter the precipitate, wash it with aqueous sodium bicarbonate solution, then vacuum-dry it, and recrystallize it in boiling n-octane to obtain reddish-orange dimethyl azobenzene dicarboxylate or its derivatives;

[0058] S2. Using the alkane group-containing dimethyl azobenzene dicarboxylate or its derivatives obtained in step S1, dimethyl terephthalat...

Embodiment 1

[0075] A photosensitive color-changing azobenzene polyester, its structural formula is as follows:

[0076]

[0077] Wherein, m is about 110, and n is about 15;

[0078] 1. Preparation of azo compound

[0079] S1. The suspension of dimethyl 5-aminoisophthalate (10.45g) was placed in hydrochloric acid solution (300mL, 0.50M), and the solution was cooled in a water-ice bath at 0-5°C. Under stirring condition, sodium nitrite (3.80 g) was dissolved in water (solution A) and added slowly. After the addition of the nitrite solution, continue to stir at low temperature for 20 minutes to finally obtain the diazonium salt suspension.

[0080] Then, sodium hydroxide (12.0g) and phenol (5.17g) were formulated into a solution (solution B), solution A was added dropwise to solution B, stirred at 5°C, and the system continued to react for 20 minutes; then the final solution was slowly It was added to acidic aqueous solution (HCl) to obtain a reddish-orange azo compound precipitate.

...

Embodiment 2-6

[0092] The photosensitive color-changing azophenyl polyester provided by Examples 2-6 and Comparative Examples 1-2, compared with Example 1, is different in that in step S3, the substance of dimethyl terephthalate and diol The ratio of the quantity n 1 :n 2 Compared with the amount of azo compound, the mass percentage w of dimethyl terephthalate is shown in Table 1, and the others are roughly the same as those in Example 1, and will not be repeated here.

[0093] Preparation conditions and performance test results of table 1 embodiment 2-6 and comparative example 1-2

[0094]

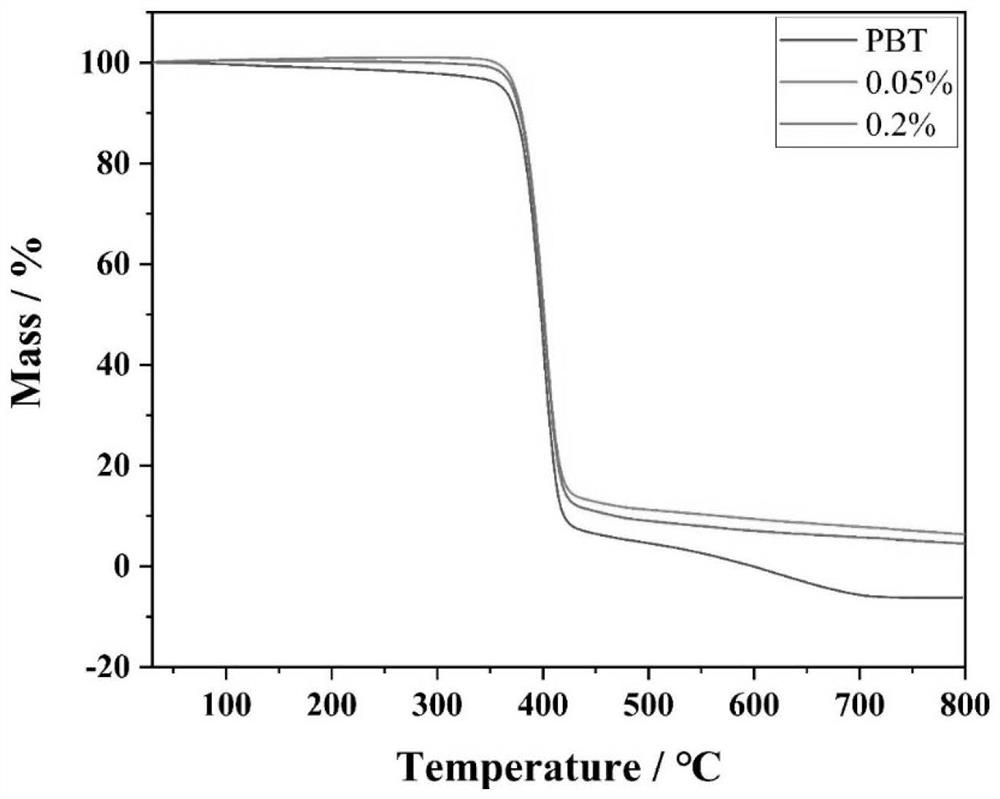

[0095] As can be seen from Table 1, when the addition amount of dimethyl azobenzene diformate was constant in the polymerization system, the ratio of the amount of dimethyl terephthalate and diol was larger, and the molecular weight of the obtained polymer was higher. Smaller, the worse the heat resistance of azobenzene polyester, the lower the onset temperature of mass loss, and the lower the tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com