Diamine, polyimide, and polyimide film and utilization thereof

A technology of polyimide film and polyimide, which is applied in the field of polyimide, can solve problems such as reaction shrinkage, warpage, and film defects, and achieve high heat resistance, low linear thermal expansion coefficient, and solution processability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

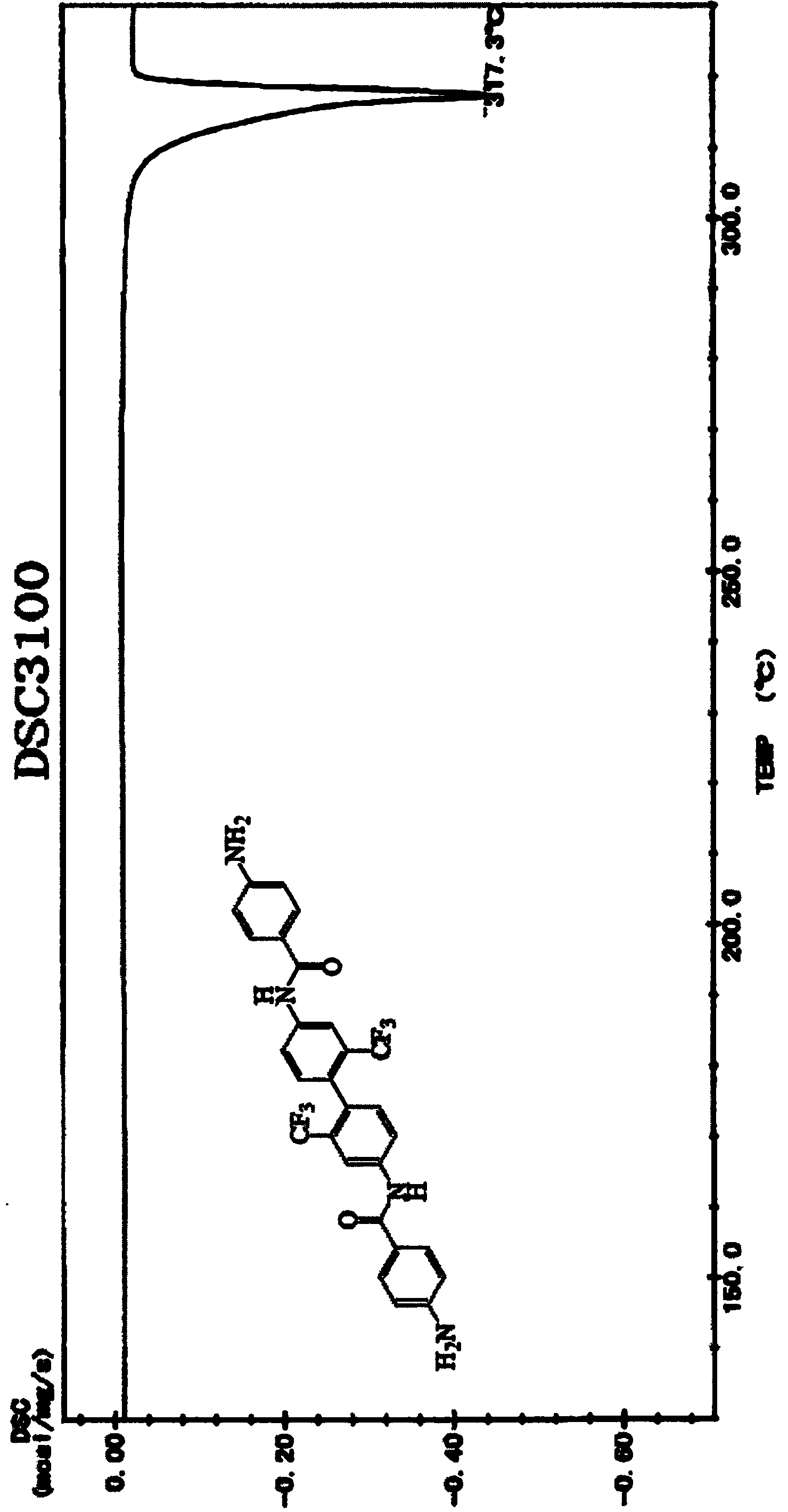

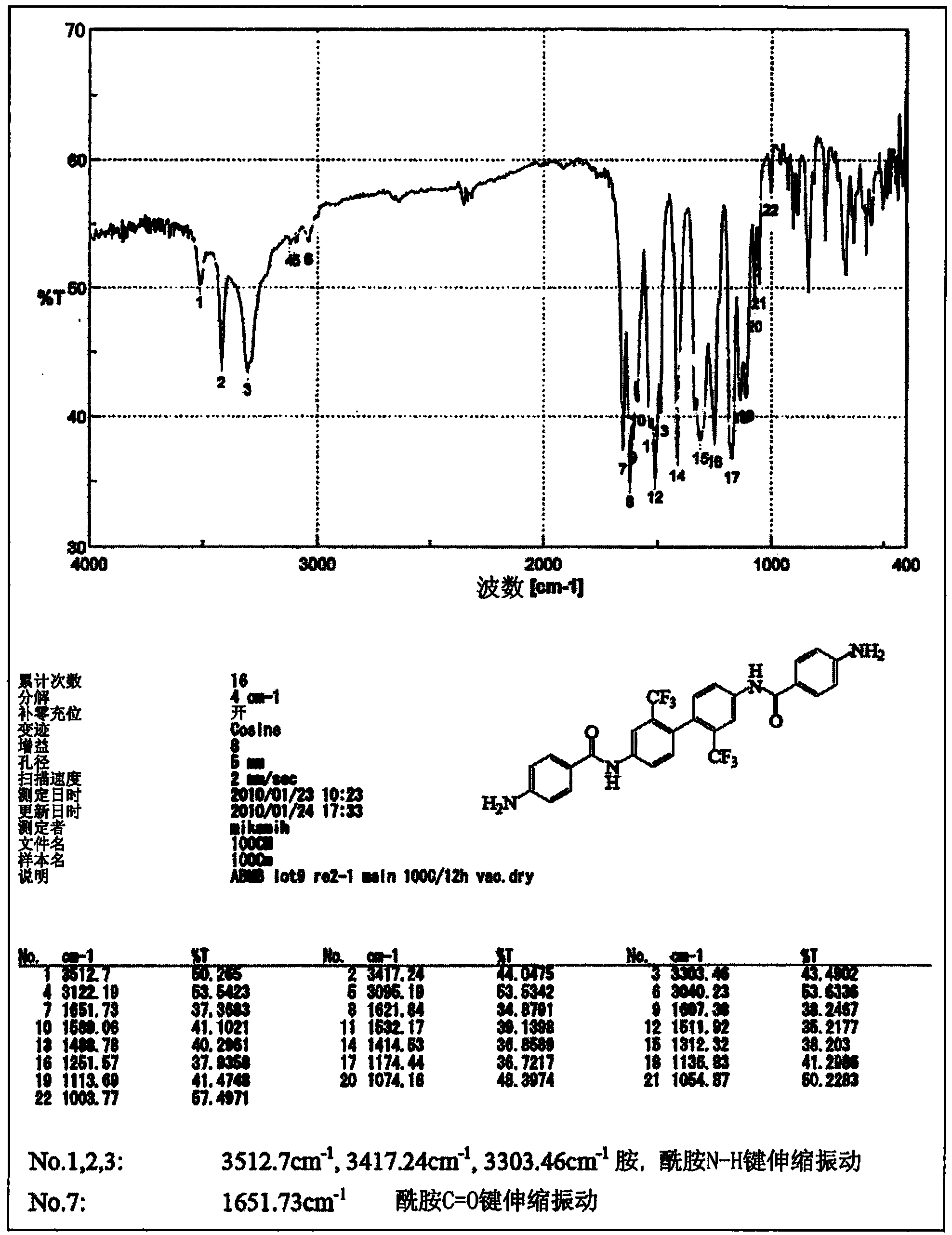

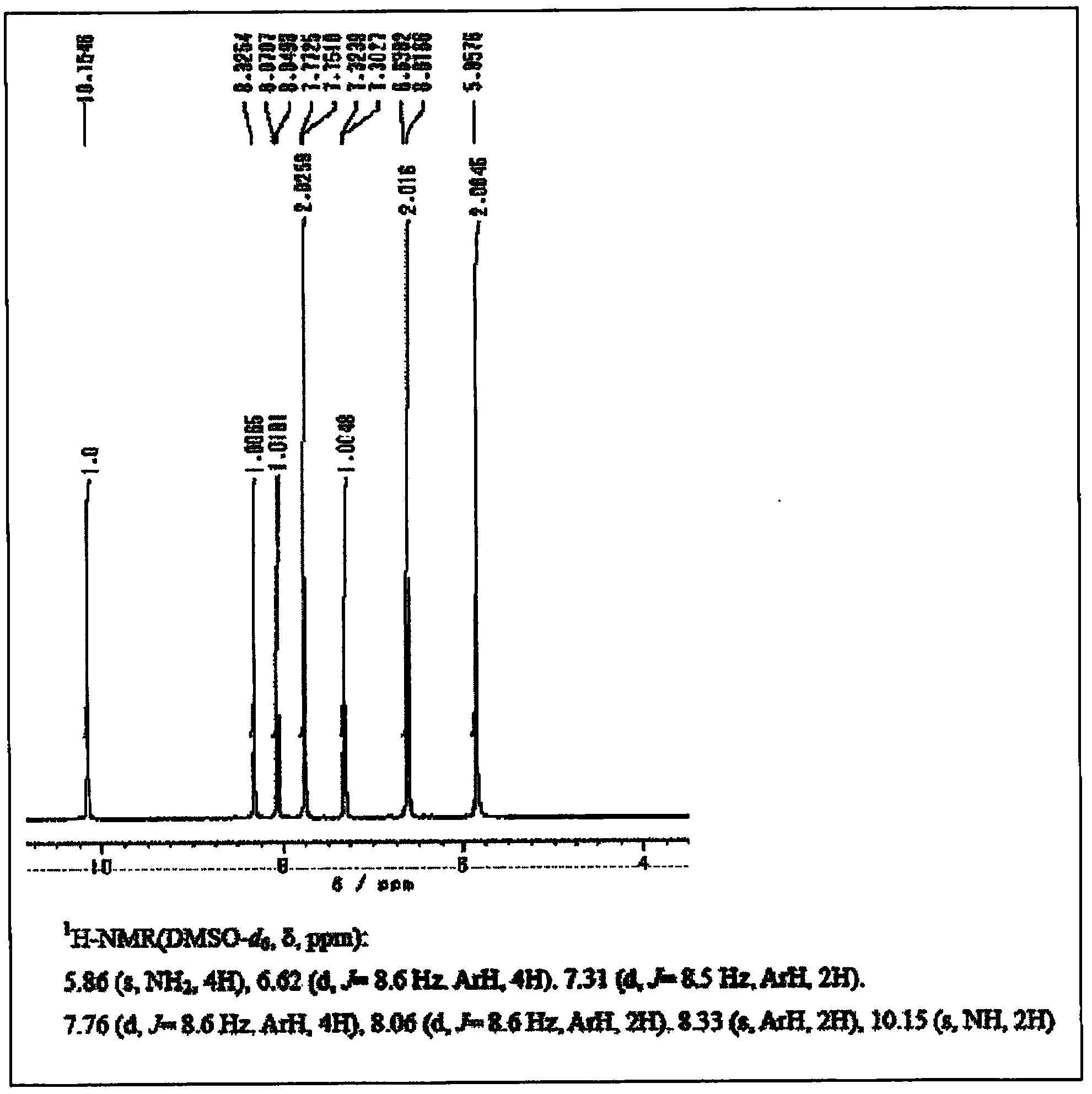

[0148] (Synthesis of diamines)

[0149] The diamine (hereinafter referred to as "ABMB") expressed by the above formula (8) was synthesized by the method represented by the above formula (13). The specific synthesis method is as follows.

[0150]

[0151] Under ice cooling, to a solution obtained by dissolving 3.8023 (20.5 mmol) of 4-nitrobenzoyl chloride (4-NBC) in 6.26 mL of tetrahydrofuran (hereinafter referred to as "THF"), 3.2023 g (10 mmol) of 2,2'-bis(trifluoromethyl)benzidine (TFMB), 1.75 mL of THF, and 3.3 mL (40 mmol) of pyridine. As a result, a large amount of yellow-white precipitate was produced. After standing still for 12 hours, the obtained yellowish-white precipitate was filtered and washed thoroughly with THF and ion-exchanged water. The obtained powder was dried under reduced pressure at 100° C. for 12 hours to obtain a nitro compound as a precursor of ABMB (hereinafter referred to as “NBMB”; yield: 5.9216 g, yield: 95.7%). The obtained product was identi...

Embodiment 2

[0159] 1.6754 g (3 mmol) of ABMB were dissolved in 5.4784 g of NMP. 0.6725 g (3 mmol) of H'-PMDA was added to the obtained solution, and it stirred at room temperature for 7 hours. With NMP, the solid content concentration of the solution obtained was diluted to 10.2% by weight, and then slowly added dropwise at room temperature in the diluted solution obtained by 3.0627g (30mmol) of acetic anhydride and 1.1865g (15mmol) of pyridine. The solvents were mixed and then stirred for 24 hours. The obtained solution was added to a large amount of methanol, thereby precipitating the target product. The obtained white precipitate was sufficiently washed with methanol, and vacuum-dried.

[0160] The obtained polyimide powder was dissolved in cyclopentanone to prepare a 3% by weight solution. This solution was cast on a glass substrate, and dried at 60° C. for 2 hours with a hot air drier. Thereafter, the dried product was peeled off from the substrate, and dried at 250° C. for 1 hou...

Embodiment 3

[0163] Except for changing the film production conditions described below, it was carried out in the same manner as in Example 2. The obtained polyimide powder was dissolved in cyclopentanone to prepare a 3% by weight solution. This solution was cast on a glass substrate, and dried at 60° C. for 2 hours with a hot air dryer. After that, the dried product on the peeled substrate was dried under vacuum at 250° C. for 1 hour, and then the dried product was peeled from the glass substrate and further heat-treated at 250° C. in vacuum for 1 hour, thereby producing Got the film. Here, two types of films were produced, one of which had a film thickness of 10 μm, and these were used to measure the average linear thermal expansion coefficient and mechanical properties. The other one had a film thickness of 15 μm, which was used to measure the refractive index.

[0164] The film obtained was measured for mechanical properties, and the result was that the average elongation was 12%, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com