A Fault Monitoring and Diagnosis Method of Electric Spindle Based on Three-phase Instantaneous Power

A technology of instantaneous power and diagnostic methods, applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve problems such as indistinct fault characteristics, high sampling requirements, and high signal frequency, and achieve obvious fault characteristic signals and concise spectrum , Spectrum Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

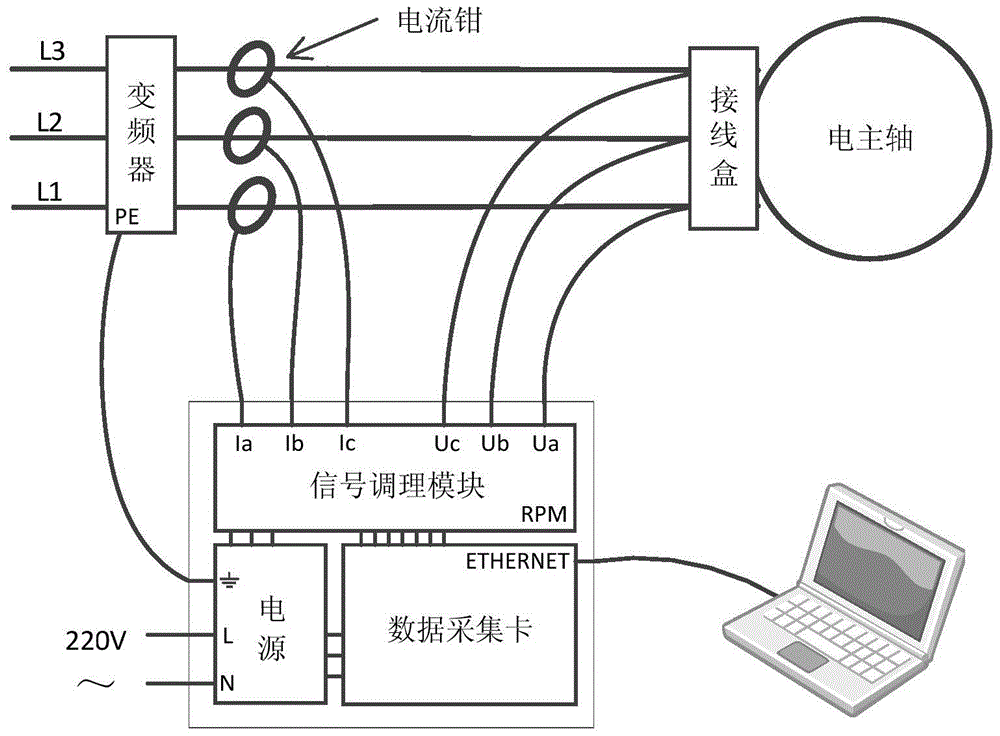

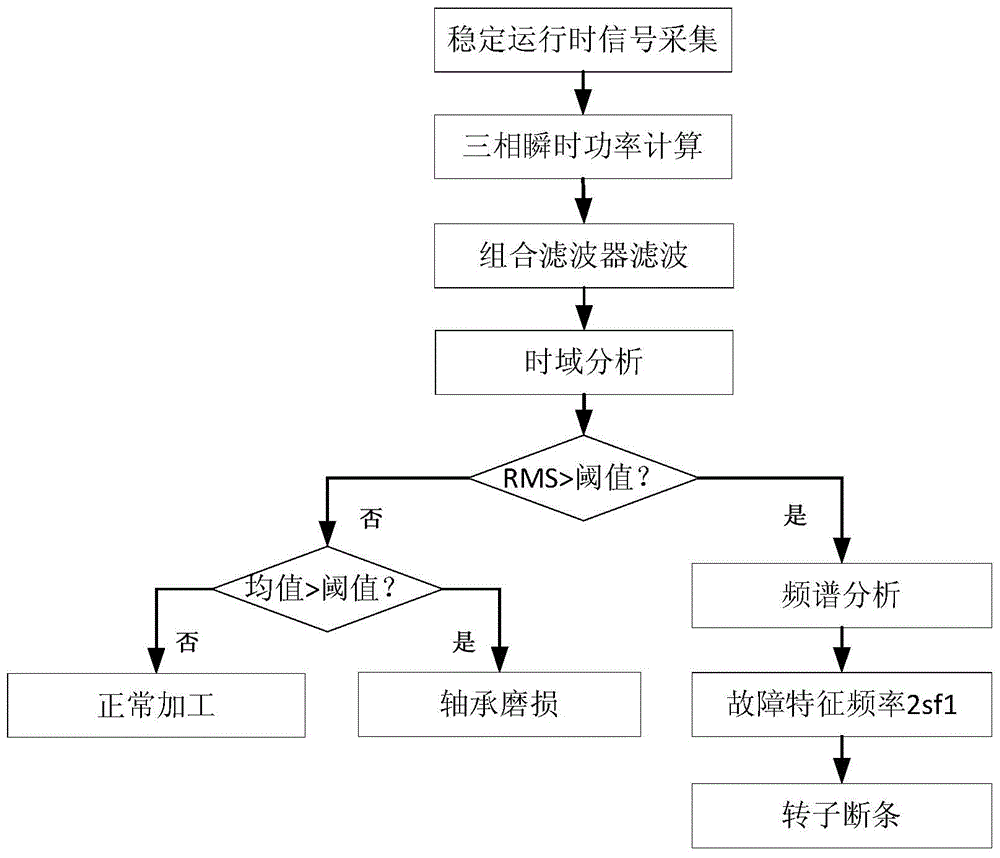

[0028] refer to figure 1 and figure 2 , a method for monitoring and diagnosing electric spindle faults based on three-phase instantaneous power of the present invention, comprising the following steps:

[0029] 1) Collect the three-phase voltage and three-phase current signals of the healthy electric spindle in the no-load operation state, and calculate the three-phase instantaneous power signal of the healthy electric spindle, set the three-phase instantaneous power signal in this state as the standard, and establish The running database of the electric spindle in a healthy state.

[0030] 2) Start the machine tool, collect the three-phase voltage and three-phase current signals of the electric spindle to be tested in the no-load state after stable operation, and obtain the three-phase instantaneous power signal of the electric spindle to be tested by calculation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com