Sputtering equipment and sputtering method

A sputtering and equipment technology, applied in the field of coating equipment, can solve the problems of large footprint, high cost, complex structure, etc., achieve continuous sputtering, simplify the process, and improve sputtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

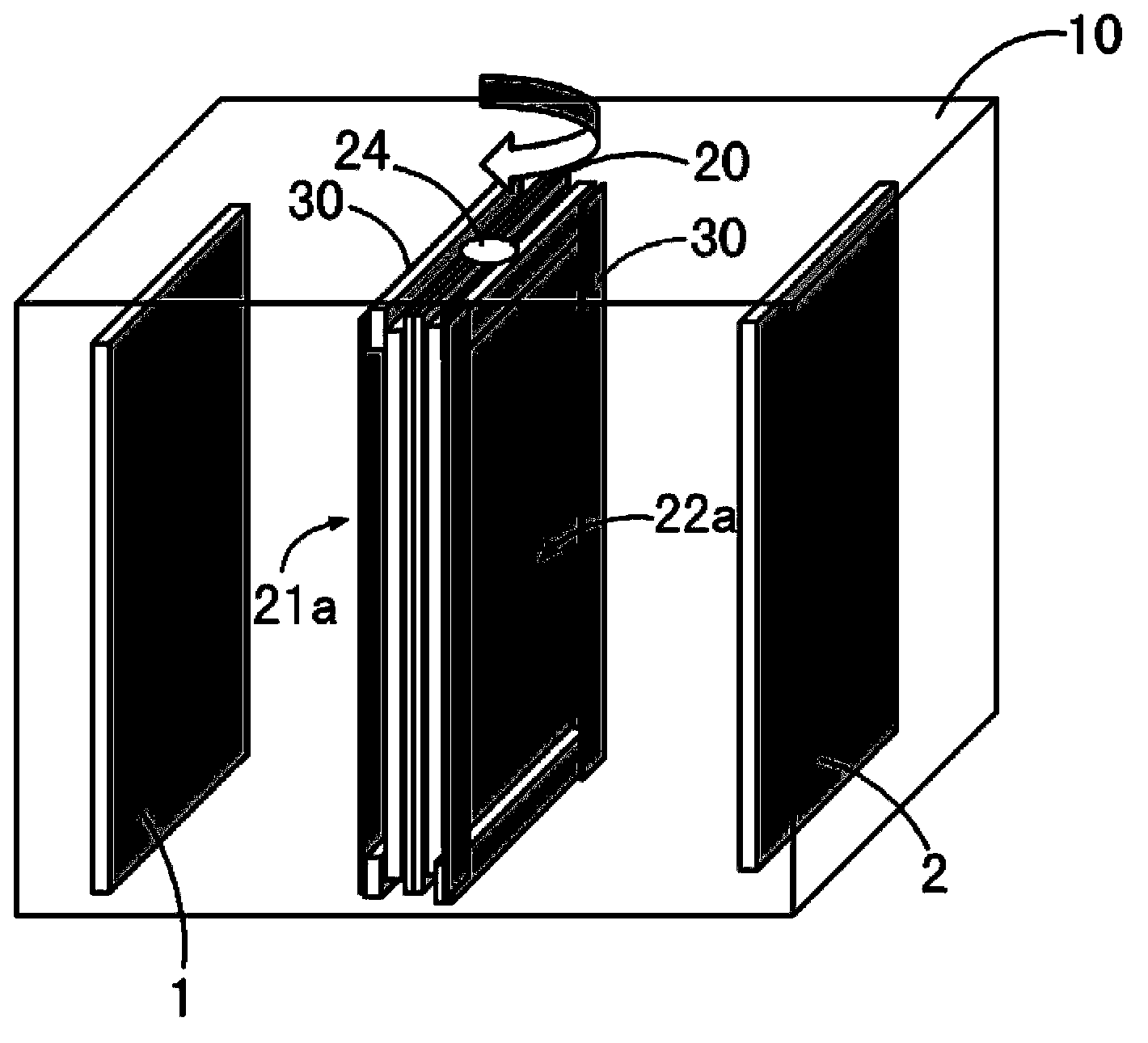

[0021] Figure 2A Shown as a schematic diagram of sputtering equipment in an embodiment of the present invention. Figure 2B shown as Figure 2A A schematic diagram of the rotating target mechanism 20 of the sputtering device.

[0022] Such as Figure 2A As shown, the sputtering equipment in one embodiment of the present invention includes a cavity 10 , a rotating target mechanism 20 and two sets of sealing mechanisms 30 . In operation, the first substrate 1 and the second substrate 2 may be disposed in a sputtering apparatus.

[0023] The cavity 10 is in the shape of a cuboid in this embodiment, and may be in any other shape in other embodiments.

[0024] The rotating target mechanism 20 is arranged in the cavity 10, and as Figure 2B As shown, it includes a first target fixture 21 , a second target fixture 22 , an insulating layer 23 and a rotating shaft 24 between the first target fixture 21 and the second target fixture 22 .

[0025] In this embodiment, the first tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com