A modified two-component road joint filling adhesive filled with acicular wollastonite with high aspect ratio

A technology of acicular wollastonite and high aspect ratio is applied in the field of modified road joint filling material and road joint filling material. Difficulty, improve stability, and facilitate the effect of sizing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

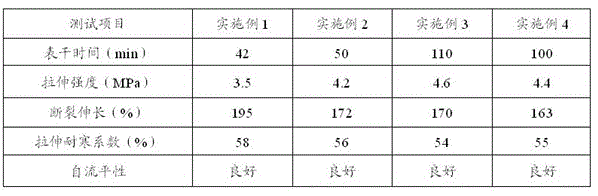

Examples

Embodiment 1

[0037] (1) Put 100 parts of compound mixed base rubber, 5 parts of acicular wollastonite with high aspect ratio and 50 parts of reinforcing filler into the mixer, start stirring and heat up to 100°C, and mix at 100°C at a speed of 1000rpm After 1 hour, vacuumize, cool to room temperature, then add 25 parts of plasticizer, 2 parts of colorant, and 1.5 parts of tackifier in sequence according to the ratio of parts by weight, then stir and vacuumize for 20 minutes; obtain component A;

[0038] (2) Mix and stir 6 parts of crosslinking agent, 0.5 part of chain extender and 0.1 part of catalyst evenly to obtain component B;

[0039] (3) Slowly add the prepared B component to the slow stirring component A, and then stir at a speed of 500rpm for 20 minutes, and after mixing evenly, the acicular silica fume with high aspect ratio for asphalt pavement crack repair is prepared Stone-filled modified two-component road joint glue.

Embodiment 2

[0041] (1) Put 100 parts of compound mixed base rubber, 10 parts of acicular wollastonite with high aspect ratio and 35 parts of reinforcing filler into the mixer, start stirring and heat up to 100°C, and mix at 100°C at a speed of 1200rpm After 1.5 hours, vacuumize, cool to room temperature, then add 50 parts of plasticizer, 4 parts of colorant, and 0.5 parts of tackifier in sequence according to the ratio of parts by weight, then stir and vacuumize for 30 minutes; obtain component A;

[0042] (2) Mix and stir 4 parts of crosslinking agent, 1 part of chain extender and 0.2 parts of catalyst evenly to obtain component B;

[0043] (3) Slowly add the prepared component B to the slow stirring component A, then stir at a speed of 300rpm for 20 minutes, and after mixing evenly, acicular silica fume with high aspect ratio for asphalt pavement crack repair is prepared Stone-filled modified two-component road joint glue.

Embodiment 3

[0045] (1) Put 100 parts of compound mixed base rubber, 15 parts of acicular wollastonite with high aspect ratio and 25 parts of reinforcing filler into the mixer, start stirring and raise the temperature to 100°C, and mix at 100°C at a speed of 1100rpm After 1.2 hours, vacuumize, cool to room temperature, then add 15 parts of plasticizer, 2.5 parts of colorant, and 0.8 parts of tackifier in sequence according to the ratio of parts by weight, then stir and vacuumize for 25 minutes; obtain component A;

[0046] (2) Mix and stir 2.5 parts of crosslinking agent, 0.8 parts of chain extender and 0.3 parts of catalyst evenly to obtain component B;

[0047] (3) Slowly add the prepared B component to the slow stirring component A, and then stir at a speed of 400rpm for 20 minutes, and after mixing evenly, the acicular silica fume with high aspect ratio for asphalt pavement crack repair is prepared Stone-filled modified two-component road joint glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com