High-strength high-toughness aluminum-silicon alloy obtained by gravity casting and preparation method thereof

A gravity casting, aluminum-silicon alloy technology, applied in the field of aluminum alloy materials, can solve the problems of increasing process complexity and increasing production costs, and achieve the effects of improving mechanical properties, reducing content and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

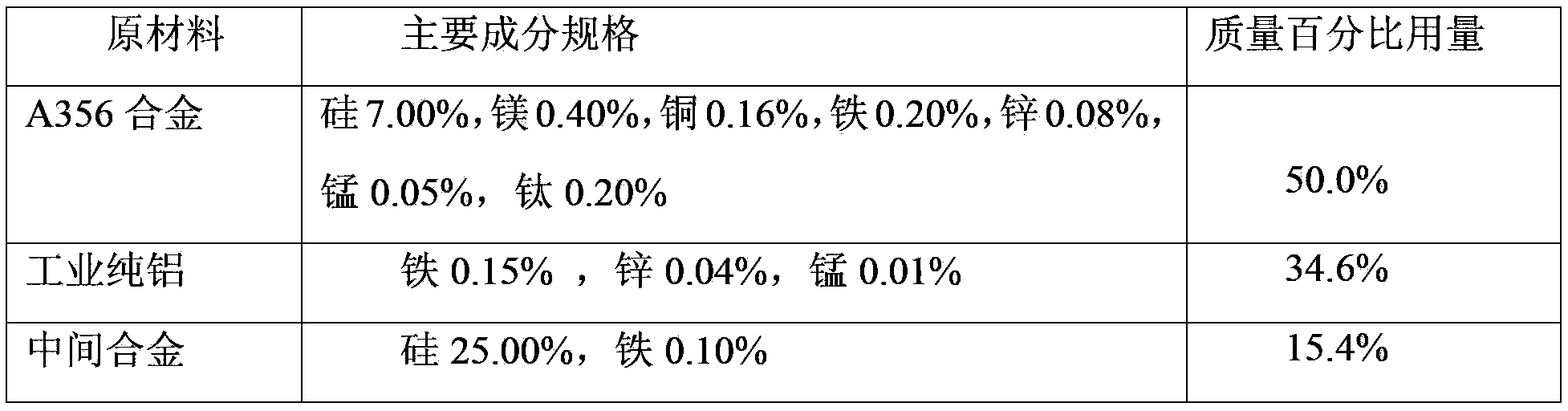

[0031] Prepare and smelt the alloy material according to the composition of the aluminum-silicon alloy of the present invention, cast a batch of automobile brake caliper body castings by using the metal mold gravity casting process, and perform T6 heat treatment; the following table 1 is the ingredient list of step 1.

[0032] Table 1 The ingredients and content of Step 1

[0033]

[0034] Step 2: Smelting

[0035] Preheat A356 alloy, industrial pure aluminum and master alloy to 200°C. Add the A356 alloy and industrial pure aluminum into the melting furnace, and the alloy melting temperature is 720-730°C. When the A356 alloy and industrial pure aluminum are melted to a paste state, add the aluminum-silicon master alloy, and spread the covering agent (the weight percentage of the covering agent composition: 50% potassium chloride + 50% sodium chloride). About 4% of the total body mass. The alloy is completely melted after heat preservation for about 1 hour, and the alumin...

Embodiment 2

[0041] According to the composition of the aluminum-silicon alloy of the present invention, the smelted alloy material is prepared, a batch of automobile brake caliper body castings are poured by a metal mold gravity casting process, and T6 heat treatment is performed.

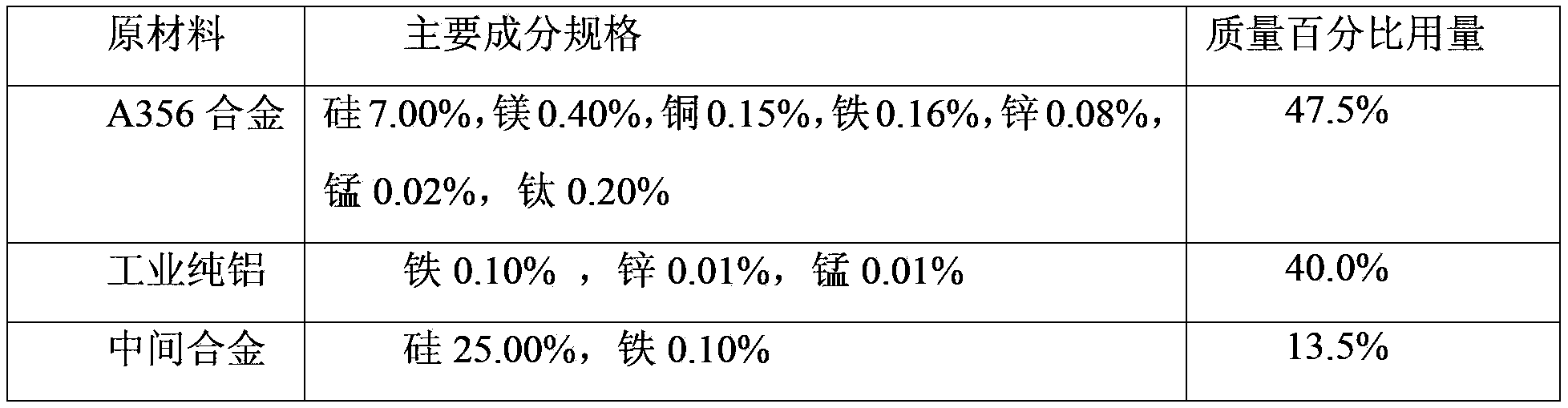

[0042] Step 1: Ingredients

[0043] Table 2 The ingredients and content of step 1

[0044]

[0045] Step 2: smelting; Step 3: heat treatment;

[0046] The processes of steps two and three are all the same as in Example one.

[0047]A batch of automobile brake caliper bodies was obtained through the above steps, and spectrometer analysis showed that the batch of casting materials contained 6.68% silicon, 0.19% magnesium, 0.13% iron, 0.07% copper, 0.10% titanium, 0.04% zinc, and 0.01% manganese. Strontium 0.008%, the rest is aluminum and a very small amount of unavoidable impurities. According to the national standard GB / T228-2002, the standard sample was taken for mechanical performance test results: tens...

Embodiment 3

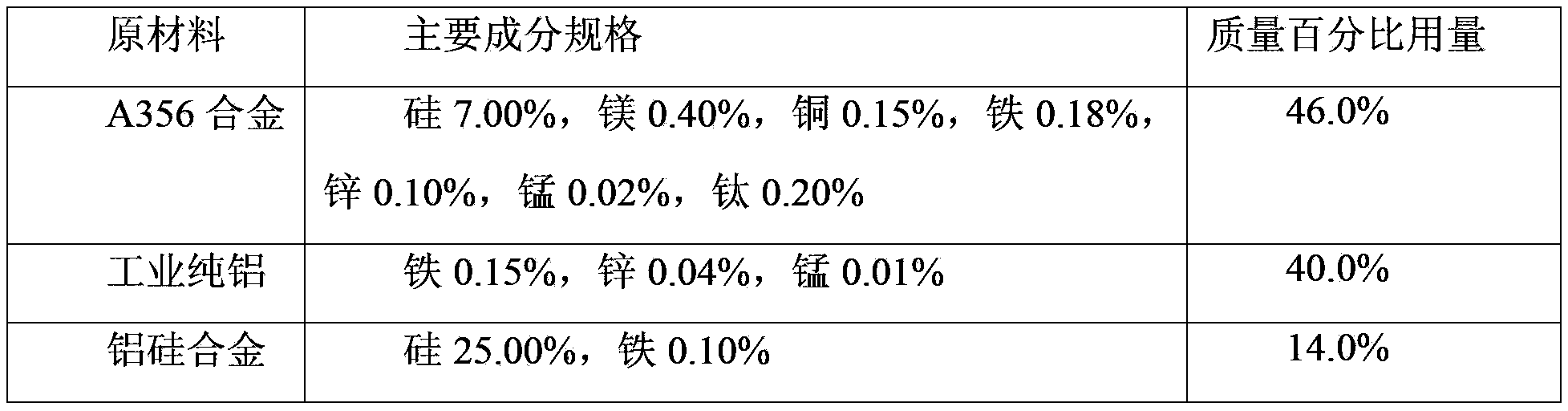

[0049] Prepare and smelt the alloy material according to the composition of the aluminum-silicon alloy of the present invention, cast a batch of communication fastener castings by using the metal mold gravity casting process, and perform T6 heat treatment; Table 3 The ingredients and contents of Step 1.

[0050] Table 3 Step 1: Ingredients

[0051]

[0052] Step 2: smelting; Step 3: heat treatment process;

[0053] The processes of steps two and three are all the same as in Example one.

[0054] The room temperature tensile mechanical properties of the alloy of the present invention and some aluminum-silicon alloys with similar silicon content are compared in the following table, and the following table 4 is a comparison table of alloy properties.

[0055] Table 4 Alloy performance comparison table

[0056]

[0057] A batch of communication fasteners was obtained through the above steps, and spectrometer analysis revealed that the batch of casting materials contained 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com