Modified silica gel material, and preparation method and application thereof

A silica gel and modification technology, which is applied in the field of modified silica gel materials, can solve problems such as potential safety hazards, sliding pots, and reducing the use efficiency of induction cookers, and achieve the effects of improving safety, increasing friction, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

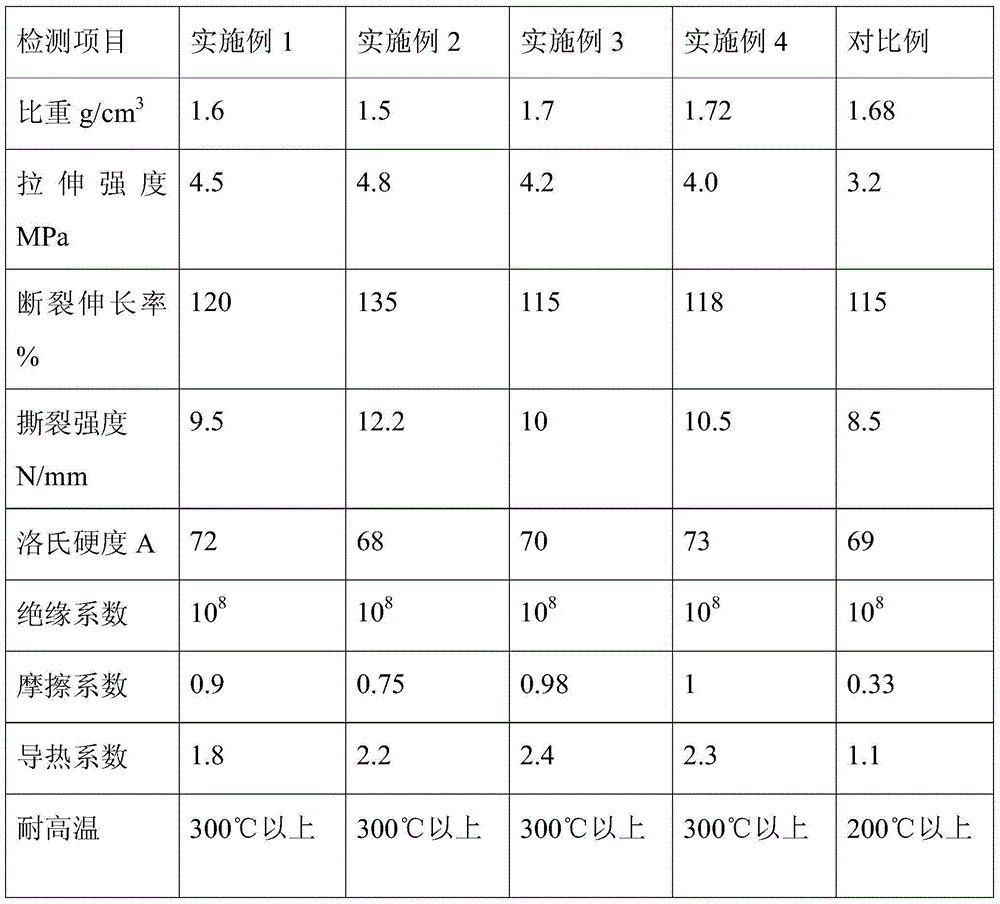

Examples

Embodiment 1

[0031] A preparation method of silica gel modified material, comprising the steps of:

[0032] (1) Mix 100kg of methyl vinyl silicone rubber, 45kg of white carbon black, 4kg of hydroxy silicone oil, 0.3kg of zinc stearate, 15kg of magnetized powder, and 25kg of alumina in a 300L internal mixer at a temperature of 150°C 90min, cooling, and filtering through a model XL (J) rubber extruder, the die head of the rubber extruder is equipped with a 200-mesh stainless steel filter screen, the frequency conversion rotation number is set at 850 rpm, and the impurities in the rubber compound are removed by filtration After that, obtain the modified silica gel raw material;

[0033] (2) Add 2kg of bis-dipentasulfurizing agent to the modified silica gel raw material obtained in step (1), mold it in a 200-ton flat vulcanizer, vulcanize for 1min at a temperature of 185°C, and press at a pressure of 100MPa to obtain a modified silica gel gasket.

Embodiment 2

[0037] (1) Mix 100kg of methyl vinyl silicone rubber, 40kg of white carbon black, 3.5kg of hydroxy silicone oil, 0.3kg of zinc stearate, 12kg of magnetized powder, and 20kg of alumina in a 300L internal mixer at a temperature of 170°C. Refining for 80 minutes, cooling, and filtering through a model XL (J) rubber extruder. The die head of the rubber extruder is equipped with a 200-mesh stainless steel filter screen, and the frequency conversion speed is set at 850 rpm to filter out impurities in the rubber compound. After that, obtain the modified silica gel raw material;

[0038] (2) Add 2kg of bis-dipentasulfurizing agent to the modified silica gel raw material obtained in step (1), mold it in a 200-ton plate vulcanizing machine, vulcanize for 40s at a temperature of 195°C, and a pressure of 100MPa to obtain a modified silica gel Material.

[0039] The magnetized powder is a magnet with magnetism. After pulverization, 2Kg of coupling agent of Foshan Daoning Chemical Co., Ltd...

Embodiment 3

[0041] (1) Mix 100kg of methyl vinyl silicone rubber, 48kg of white carbon black, 4.5kg of hydroxy silicone oil, 0.4kg of zinc stearate, 20kg of magnetized powder, and 22kg of alumina in a 300L internal mixer at a temperature of 140°C. Refining for 120min, cooling, and filtering through a model XL (J) rubber extruder. The die head of the rubber extruder is equipped with a 200-mesh stainless steel filter screen, and the frequency conversion speed is set at 850 rpm to filter out impurities in the rubber compound. After that, obtain the modified silica gel raw material;

[0042] (2) Add 2kg of bis-dipentasulfurizing agent to the modified silica gel raw material obtained in step (1), mold it in a 200-ton flat vulcanizing machine, vulcanize for 70s at a temperature of 180°C, and a pressure of 100MPa to obtain a modified silica gel Material.

[0043] The magnetized powder is a magnet with magnetism. After crushing, add 1.3Kg of Foshan Daoning Chemical Co., Ltd., model: A-171 coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com