Production method of washable spunlace pure-cotton quilt and quilt core as well as washable spunlace pure-cotton quilt

A production method and spunlace technology, which are applied in textiles and papermaking, non-woven fabrics, bed sheets, etc., can solve the problem of inconvenient cleaning of the quilt core, and achieve the effect of poor hydrophilicity and hard to harden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

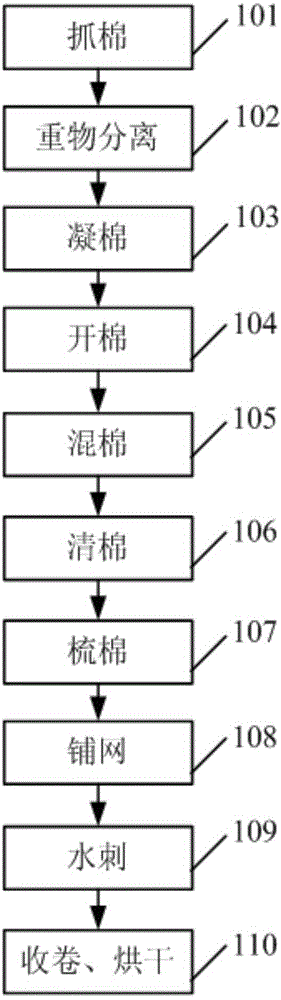

[0022] Please refer to figure 1 , the present embodiment provides a method for manufacturing a spunlace washable pure cotton quilt core, comprising the following steps:

[0023] Step 101: Grab pure cotton raw materials that meet the specifications. The present embodiment adopts the reciprocating cotton grabbing machine to grab pure cotton raw materials, which is suitable for grabbing various grades of raw cotton, cotton-type chemical fibers and medium-length fibers below 76 mm. In other embodiments, other cotton grabbing machines can also be used.

[0024] Step 102: Separating and removing the heavy objects mixed in the pure cotton raw material. In this embodiment, the heavier impurities are separated and removed from the pure cotton fibers by the suction of the fan airflow through the heavy object separator. In a specific ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com