Insulating varnish and preparation method thereof

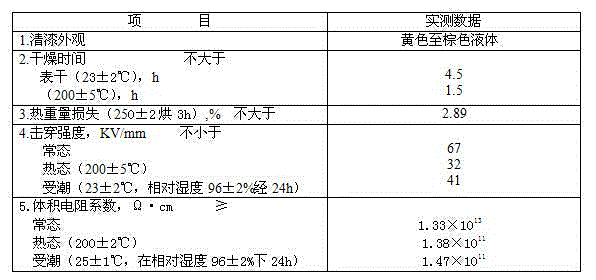

An insulating varnish, No. 1 technology, applied in the field of coatings, can solve problems such as unsatisfactory insulation properties, achieve high insulation levels, meet high temperature resistance requirements, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

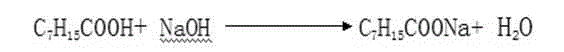

[0032] The preparation method of insulating varnish of the present invention, comprises the steps:

[0033] (1) Hydrolysis

[0034] 1.1) Add tap water and xylene to the hydrolysis tank, wherein the amount of xylene added is 1 / 3 of its weight percentage.

[0035] 1.2) Add methylphenyldichlorosilane, monophenyltrichlorosilane, diphenyldichlorosilane and xylene into the batching tank, stir evenly and then pump into the high level tank, among which, the amount of xylene added is its share 1 / 3 of the weight percentage.

[0036] 1.3) After turning on the stirring device and interlayer cooling water of the hydrolysis kettle, evenly drop the mixture in the high-level tank into the hydrolysis kettle. The hydrolysis temperature in the hydrolysis kettle is controlled within the range of 25°C to 30°C. Insulate and stir for half an hour, turn off the stirring device and interlayer cooling water of the hydrolysis kettle.

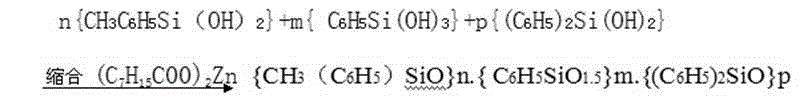

[0037] The chemical reaction formula of hydrolysis is:

[0038] ...

Embodiment 1

[0074] As a preference for the present invention, the insulating varnish described in this implementation includes the following components in weight percentage: 5% of methylphenyldichlorosilane, 6% of monophenyltrichlorosilane, 3.5% of diphenyldichlorosilane, caprylic acid Zinc 0.02%, xylene 25%, tap water 60.48%. The zinc octoate described in this example is self-made zinc octoate.

[0075] The preparation method of insulating varnish described in the present embodiment comprises the steps:

[0076] (1) Hydrolysis

[0077] 1.1) Add 60.48 parts of tap water and xylene to the hydrolysis kettle. It should be noted that the amount of xylene added is 25 / 3 parts, which is about 8.33 parts.

[0078] 1.2) Add 5 parts of methylphenyldichlorosilane, 6 parts of monophenyltrichlorosilane, 3.5 parts of diphenyldichlorosilane and xylene into the batching kettle, stir evenly and then pump into the high level tank. It should be noted that, The addition of xylene is 25 / 3 parts, about 8.33...

Embodiment 2

[0090] As a preference for the present invention, the insulating varnish described in this implementation includes the following components in weight percentage: 4% of methylphenyldichlorosilane, 5% of monophenyltrichlorosilane, 3% of diphenyldichlorosilane, octanoic acid Zinc 0.01%, xylene 30%, tap water 57.89%. The zinc octoate described in this embodiment is commercially available zinc octoate.

[0091] The preparation method of insulating varnish described in the present embodiment comprises the steps:

[0092] (1) Hydrolysis

[0093] 1.1) Add 57.89 parts of tap water and xylene to the hydrolysis tank. It should be noted that the amount of xylene added is 10 parts.

[0094] 1.2) Add 4 parts of methylphenyldichlorosilane, 5 parts of monophenyltrichlorosilane, 3 parts of diphenyldichlorosilane and 10 parts of xylene into the batching tank, stir well and then pump into the high level tank.

[0095]1.3) After turning on the stirring device and interlayer cooling water of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com