Low-voltage varistor ceramic chip and preparation method thereof, and preparation method of low-voltage varistor

A technology of varistors and varistors, which is applied in the direction of varistors, overvoltage protection resistors, resistors, etc., and can solve problems such as poor lightning protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

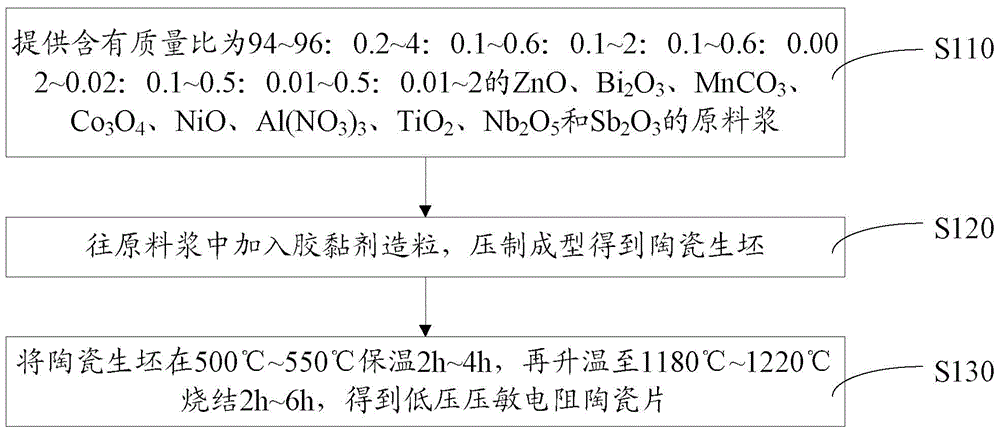

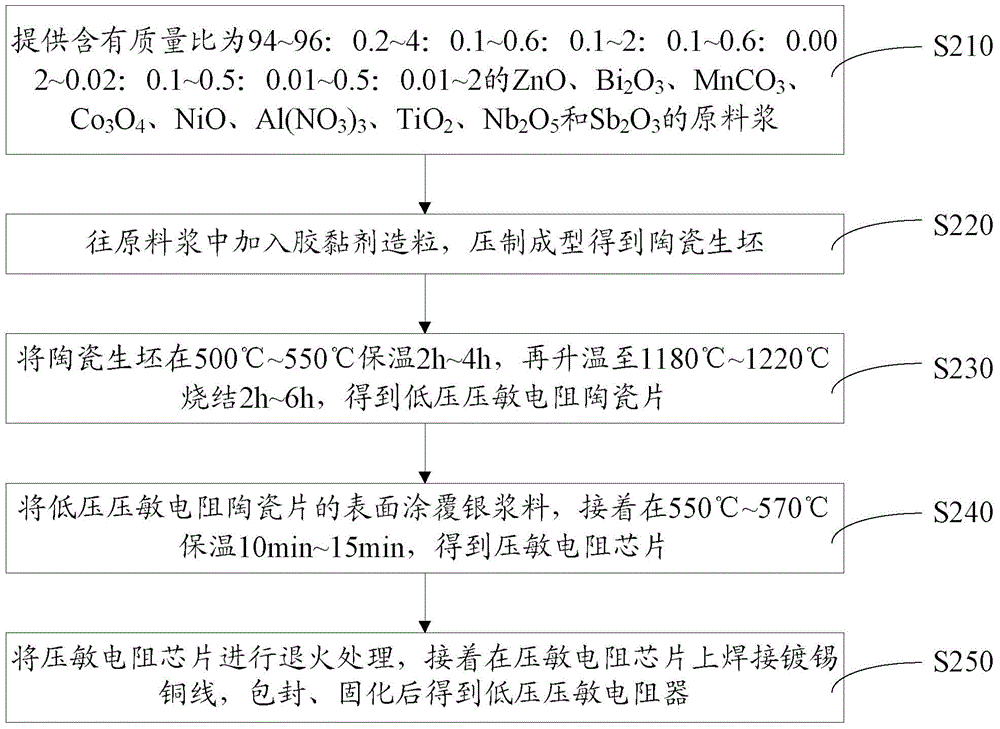

[0034] Such as figure 1 Shown, the preparation method of the low-voltage varistor ceramic sheet of an embodiment, comprises the following steps:

[0035] S110, providing ZnO and Bi with a mass ratio of 94-96: 0.2-4: 0.1-0.6: 0.1-2: 0.1-0.6: 0.002-0.02: 0.1-0.5: 0.01-0.5: 0.01-2 2 o 3 , MnCO 3 、Co 3 o 4 , NiO, Al(NO 3 ) 3 、TiO 2 , Nb 2 o 5 and Sb 2 o 3 raw material slurry.

[0036] Raw material slurry in S110 can be prepared through the following steps:

[0037] S112. Set the mass ratio of Bi to 0.2-4: 0.1-0.6: 0.1-2: 0.1-0.6: 0.002-0.02: 0.1-0.5: 0.01-0.5: 0.01-2 2 o 3 , MnCO 3 、Co 3 o 4 , NiO, Al(NO 3 ) 3 、TiO 2 , Nb 2 o 5 and Sb 2 o 3 The mixture was mixed with deionized water and ground to form a slurry.

[0038] The operation of grinding the mixture into a slurry can use a sand mill to grind the mixture to form a slurry. Grinding until the particle size D50 value of the slurry is less than 1 μm.

[0039] S114, add ZnO and deionized water to the s...

Embodiment 1

[0077] Bi with a mass ratio of 0.2:0.1:0.1:0.1:0.02:0.1:0.5:0.01 2 o 3 , MnCO 3 、Co 3 o 4 , NiO, Al(NO 3 ) 3 、TiO 2 , Nb 2 o 5 and Sb 2 o 3 After mixing the mixture and water equal in mass to the mixture, grind it with a sand mill to form a slurry. The particle size D50 value of the slurry is less than 1 μm.

[0078] Pump the slurry into the ball mill tank, then add ZnO and deionized water to the slurry, ZnO and Bi 2 o 3 The mass ratio is 94:0.2, the amount of deionized water added is the same as that of ZnO, followed by ball milling for 24 hours to obtain raw material slurry.

[0079] Add polyvinyl alcohol aqueous solution with a total mass of 18% of the raw material slurry to the raw material slurry, granulate by spray drying, and make the raw material slurry into a dry powder. Then use a press to dry press to obtain a ceramic green body.

[0080] After the ceramic green body is kept at 500°C for 3h, the temperature is raised to 1220°C, and then sintered for 2...

Embodiment 2

[0085] Bi with a mass ratio of 1.2:0.4:0.6:0.2:0.02:0.5:0.1:0.01 2 o 3 , MnCO 3 、Co 3 o 4 , NiO, Al(NO 3 ) 3 、TiO 2 , Nb 2 o 5 and Sb 2 o 3 After mixing the mixture and water equal to the quality of the mixture, use a sand mill to grind to form a slurry with a particle size D50 value of less than 1 μm.

[0086] Pump the slurry into the ball mill tank, then add ZnO and deionized water to the slurry, ZnO and Bi 2 o 3 The mass ratio of ZnO was 97:1.2, the amount of deionized water added was the same as that of ZnO, and then ball milled for 16 hours to obtain raw material slurry.

[0087] Add PVA glue with 20% of the total mass of the raw material slurry to the raw material slurry, mix evenly, and then make a dry powder by spray drying. Then use a press to dry press to obtain a ceramic green body.

[0088] The ceramic green body is kept at 550°C for 2 hours to remove the glue, then the temperature is raised to 1200°C, and then sintered for 4 hours to obtain a low-vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com