Method for preparing compound type multi-element flocculating agent aluminum ferric sulfate chloride polysilicate by utilizing waste acid

A technology of aluminum ferric silicate chlorinated sulfate and silicate chlorinated sulfuric acid, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unenvironmental protection, uneconomical, consumption of mineral resources and hydrochloric acid resources, etc. Fast, low cost, good effect of decolorization and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

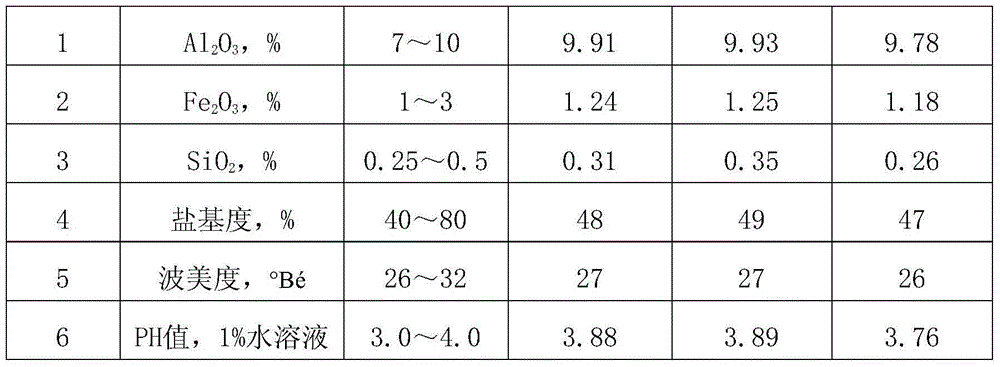

Examples

Embodiment 1

[0024] A method for preparing a composite multi-element flocculant polysilicate aluminum ferric sulfate chloride by using waste acid, comprising the following steps:

[0025] (l) Dissolving oxidation

[0026] will contain Al 2 o 3 It is 28% dry waste aluminum slag, containing 20% H 2 SO 4 , 3% Fe waste sulfuric acid, 17% Fe ferrous sulfate heptahydrate, 28% HCl waste hydrochloric acid and NaClO 3 ≥98% industrial grade sodium chlorate as raw material, mix 200 parts of waste sulfuric acid with 100 parts of waste hydrochloric acid by weight, add 250 parts of dry waste aluminum slag, heat up to 95°C, keep warm and stir for 1 hour. Add 30 parts of ferrous sulfate heptahydrate under stirring, control the temperature at 40°C, add 5 parts of sodium chlorate, keep warm and stir for 1 hour, and Fe 2+ all converted to Fe 3+ ;

[0027] (2) precipitation polymerization filtration

[0028] Add 50 parts of waste hydrochloric acid to the slurry in step (1) under stirring, after heat...

Embodiment 2

[0034] A method for preparing a composite multi-element flocculant polysilicate aluminum ferric sulfate chloride by using waste acid, comprising the following steps:

[0035] (l) Dissolving oxidation

[0036] will contain Al 2 o 3 It is 28% dry waste aluminum slag, containing 20% H 2 SO 4 , 3% Fe waste sulfuric acid, 17% Fe ferrous sulfate heptahydrate, 28% HCl waste hydrochloric acid and NaClO 3 ≥98% industrial grade sodium chlorate as raw material, mix 210 parts of waste sulfuric acid with 90 parts of waste hydrochloric acid by weight, add 260 parts of dry waste aluminum slag, heat up to 95°C, keep warm and stir for 1 hour. Add 32 parts of ferrous sulfate heptahydrate under stirring, control the temperature at 40°C, add 5 parts of sodium chlorate, keep warm and stir for 1 hour, and Fe 2+ all converted to Fe 3+ ;

[0037] (2) precipitation polymerization filtration

[0038] Add 52 parts of waste hydrochloric acid to the slurry in step (1) under stirring, add 52 part...

Embodiment 3

[0044] A method for preparing a composite multi-element flocculant polysilicate ferric aluminum sulphate chloride by using waste acid, comprising the steps of:

[0045] (l) Dissolving oxidation

[0046] will contain Al 2 o 3 It is 28% dry waste aluminum slag, containing 20% H 2 SO 4 , 3% Fe waste sulfuric acid, 17% Fe ferrous sulfate heptahydrate, 28% HCl waste hydrochloric acid and NaClO 3 ≥98% industrial grade sodium chlorate as raw material, mix 180 parts of waste sulfuric acid with 120 parts of waste hydrochloric acid by weight, add 240 parts of dry waste aluminum slag, heat up to 95°C, keep warm and stir for 1 hour. Add 28 parts of ferrous sulfate heptahydrate under stirring, control the temperature at 40°C, add 5 parts of sodium chlorate, keep warm and stir for 1 hour, and Fe 2+ all converted to Fe 3+ ;

[0047] (2) precipitation polymerization filtration

[0048] Add 48 parts of waste hydrochloric acid to the slurry in step (1) under stirring, add 49 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com