Drug-loaded egg protein microspheres and preparation method thereof

A technology for egg protein and egg white, which is applied in the field of drug controlled release, can solve the problems of restricting production and application, restricting large-scale production, complex extraction process, etc., achieving controllable particle size distribution, and improving encapsulation and controlled release effects. , the effect of good dispersion of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of drug-loaded egg protein microspheres of the present invention has the following steps:

[0039] a, the preparation of oily phase: surfactant is mixed with oily component, and wherein, described surfactant is the mixing of Siban type surfactant and Tween type surfactant, and the hydrophilic-hydrophobic balance value of surfactant is 4 ~10, the oily component is liquid paraffin, olive oil or sunflower oil;

[0040] b. Emulsification: Add the mixture of egg white and medicine to the oil phase and stir to emulsify to form a W / O phase to obtain an emulsion. The stirring time is 15-50 minutes, and the rotation speed during stirring is not higher than 1000r / min;

[0041] c. Curing: the emulsion is directly heated and solidified or cross-linked and solidified by adding an aldehyde curing agent to obtain a cured liquid, wherein the aldehyde curing agent is glutaraldehyde or vanillin;

[0042] d, demulsification: the solidified liquid is mixed with an e...

Embodiment 1

[0051] Take by weighing Span-80 (Span-80) and Tween-60 (Tween-60) that mass ratio is 5:4, wherein the quality of Span-80 is 1.0g, and the HLB value of emulsifier is 9.1, and 47g The liquid paraffin was mixed and stirred uniformly for 15min, poured into the mixed solution the mixed solution of 10g egg white liquid (12% protein content) and 80mg gentamycin sulfate, continued to stir for 30min, the stirring speed was 180r / min, after that the mixed solution Stir in a constant temperature water bath at 80°C for 15 minutes, and the protein solidifies into balls during the heating process. Take out the above mixed solution from the water bath, add petroleum ether equal to the volume of the mixed solution for demulsification, stir for 15 minutes, separate the water and oil phases and centrifuge, then wash with isopropanol and centrifuge 3 times to prepare protein microspheres and The obtained samples were stored freeze-dried.

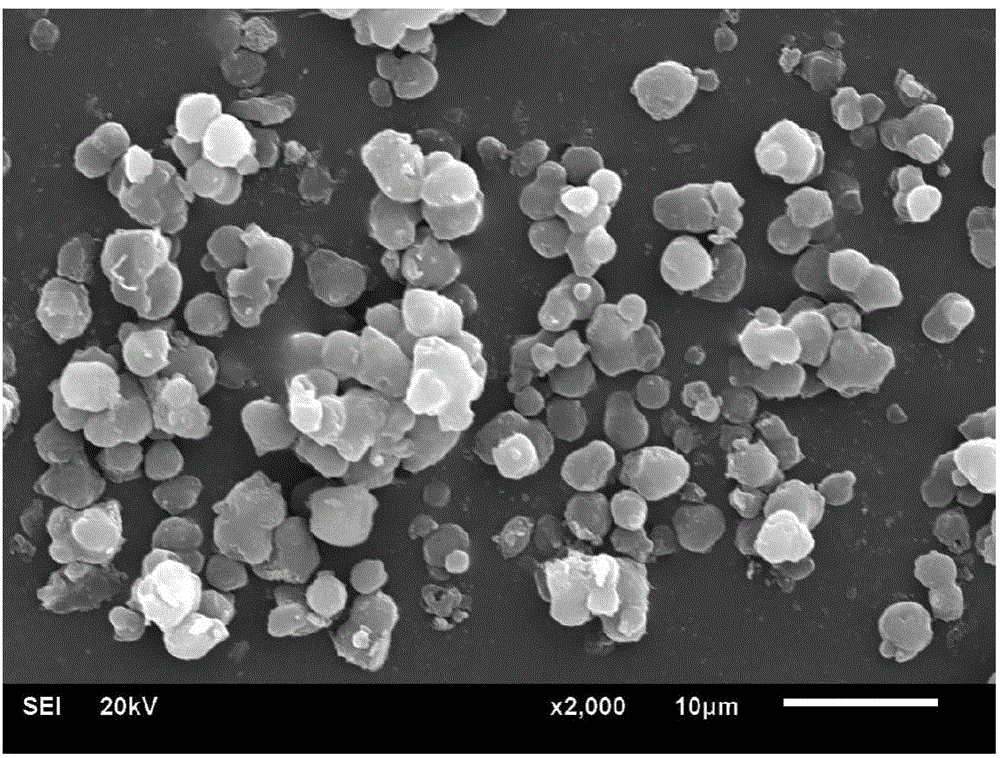

[0052] The scanning electron micrographs of the drug-loa...

Embodiment 2

[0054] Take by weighing Span-80 (Span-80) and Tween-80 (Tween-80) that mass ratio is 5:3, wherein the quality of Span-80 is 1.0g, and the HLB value of emulsifier is 8.3, and 47g Olive oil was mixed and evenly stirred for 15min, poured into the mixed solution the mixed solution of 10g egg white liquid (12% protein content) and 160mg berberine hydrochloride, continued to stir for 30min, and the stirring speed was 160r / min, after which the mixed solution was Stir in a constant temperature water bath at 80°C for 15 minutes, and the protein solidifies into balls during the heating process. Take out the above mixed solution from the water bath, add petroleum ether equal to the volume of the mixed solution for demulsification, stir for 15 minutes, separate the water and oil phases and centrifuge, then wash with isopropanol and centrifuge 3 times to prepare protein microspheres and The obtained samples were stored freeze-dried.

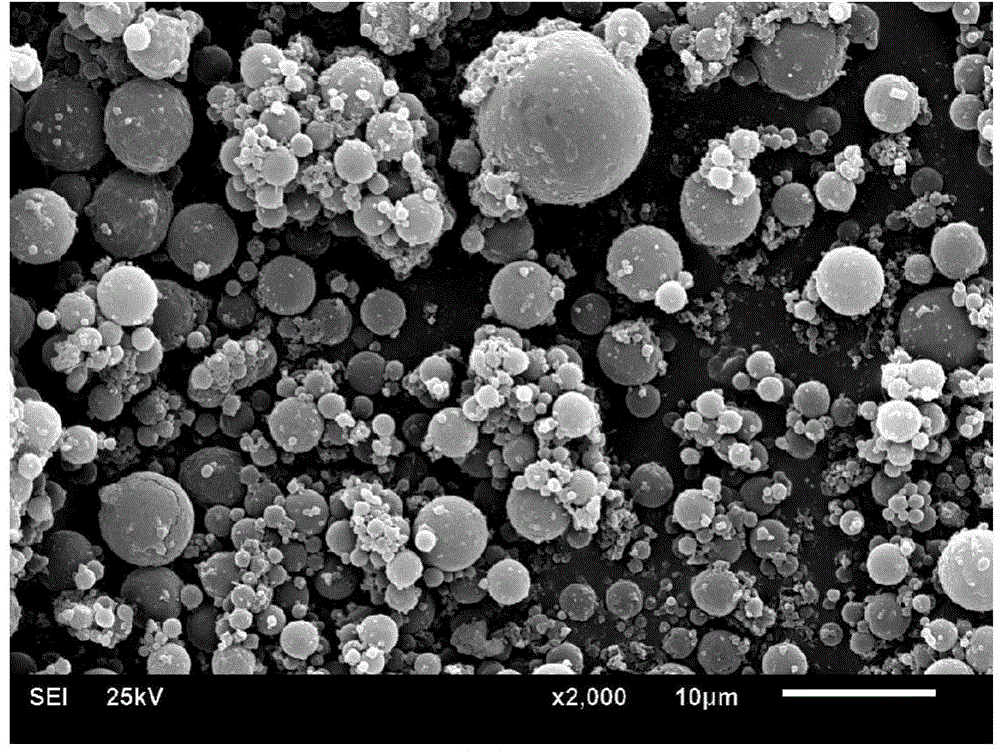

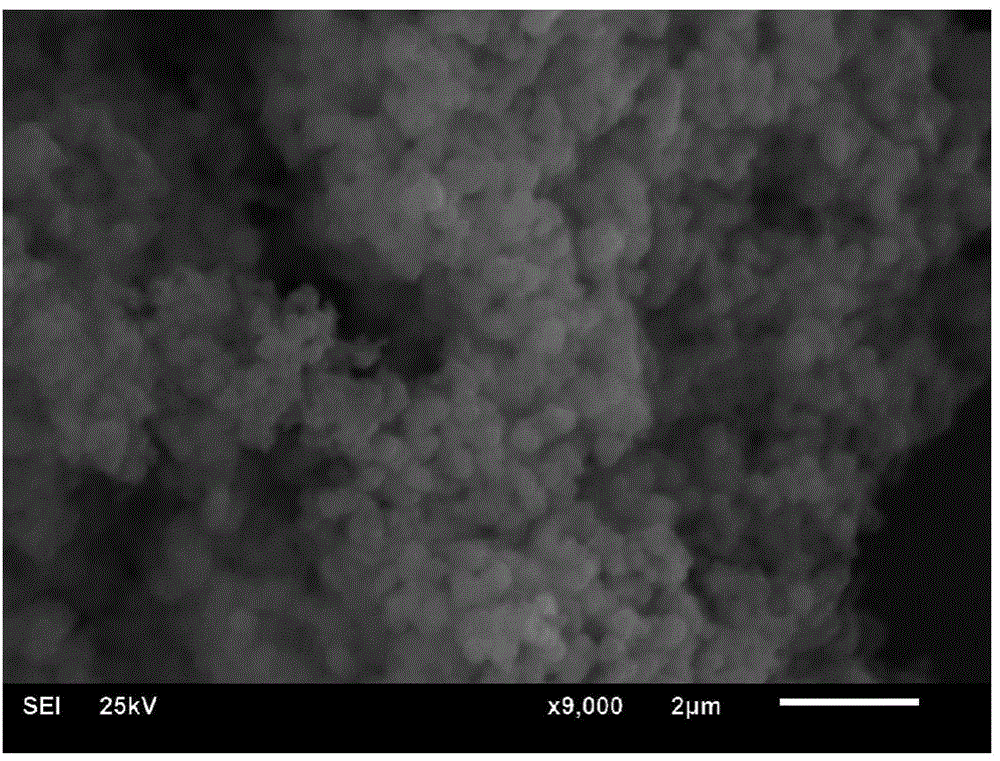

[0055] The scanning electron micrographs of the drug-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com