Magnetic iron-oxide nanoparticle covering method using silicon dioxide

A magnetic iron oxide and nanoparticle technology, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems such as cumbersome operation process and limited application in the field of biomedicine, and achieve simple process and difficult spontaneous formation Good effect of nucleus, size uniformity and shape controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 2mmol of iron acetylacetonate and 25mL of triethylene glycol into a three-necked flask and mix thoroughly. After passing through nitrogen for 2 minutes, heat and stir, raise the temperature to 180°C at a uniform speed (1°C / min), keep it warm for 10 minutes, and then rapidly raise the temperature (5°C / min) to Boil, keep boiling for 30 minutes to stop the reaction, cool to room temperature, add 10ml of absolute ethanol to dilute, then add 30ml of ethyl acetate for flocculation, separate with a magnet, wash with ethyl acetate for 3 times, and then ultrasonically disperse into deionized water to obtain Fe 3 o 4 Nanoparticle sol.

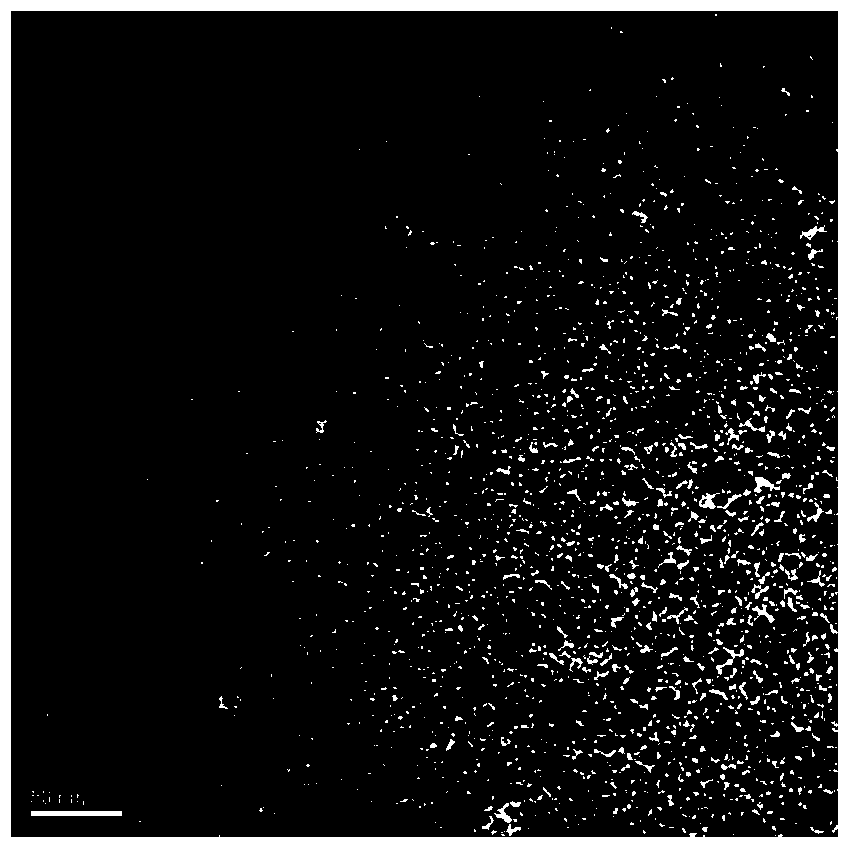

[0025] figure 1 Shown is the Fe obtained in this example 3 o 4 Transmission electron microscope (TEM) image of nanoparticles.

Embodiment 2

[0026] Embodiment 2 coprecipitation method prepares Fe 3 o 4 Nanoparticle sol

[0027] Weigh 7.8176g FeCl 6H 2 O and 3.7644g FeSO 4 ·7H 2 O, put it into a four-necked flask, and add 80ml deionized water, pass N 2 Protect. Stir, heat to constant temperature to 80°C, add 10ml NH 3 ·H 2 O, heat preservation reaction 60min. After the reaction is completed, the black solid is separated from the reaction solution with a magnet, washed 3 times with deionized water, and then ultrasonically dispersed in deionized water to obtain Fe 3 o 4 Nanoparticle sol.

Embodiment 3

[0029] With the prepared Fe in embodiment 1 or embodiment 2 3 o 4 The nanoparticle sol was exposed to air for two months to obtain partial oxidation of Fe 3 o 4 Nanoparticle sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com