Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

An iron-based amorphous alloy and iron-based amorphous technology, which can be used in magnetic materials, magnetic objects, electrical components, etc., and can solve the problems of uneven distribution, high alloy cost, and low saturation magnetization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

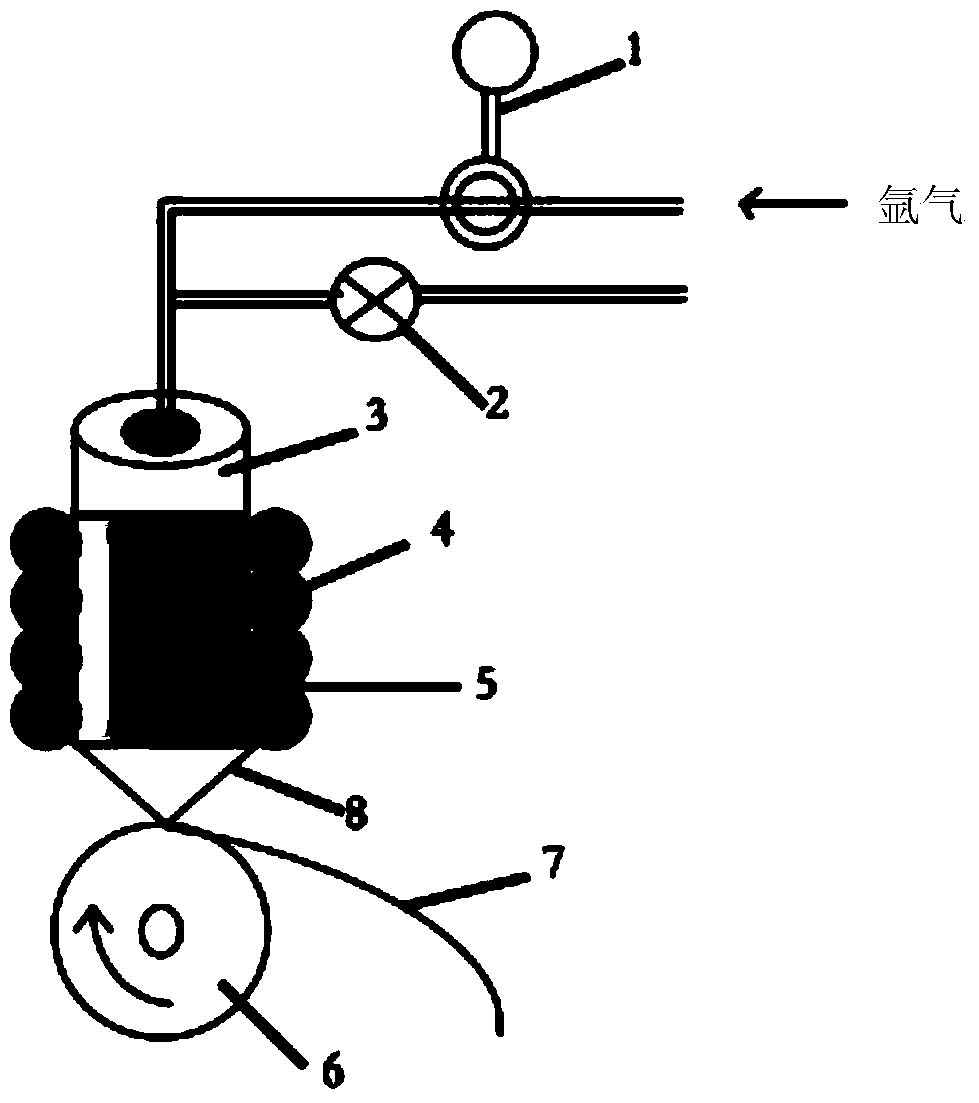

[0047] The key three steps of the single roll melt rapid quenching method described in the preparation method of the present invention are: A melting alloy step, by figure 1 The crucible shown in is used to complete the melting of the alloy; B throws out the step, under high vacuum and argon protection atmosphere, the molten alloy solution in the crucible is thrown out by the nozzle, which is formed by figure 1 Middle nozzle and crucible system to complete; C cooling step, used to cool the alloy solution coming out of the nozzle, thereby forming an amorphous strip, which is composed of figure 1 Middle quenching roller to complete.

[0048] figure 1 It is a commonly used equipment for the single-roll melt quenching method of the present invention, which includes a crucible 3; an induction heating coil 4 arranged outside the crucible; a nozzle 8 arranged at the bottom of the crucible 3 for ejecting molten alloy 5 melted in the crucible; The quenching roller 6 arranged under th...

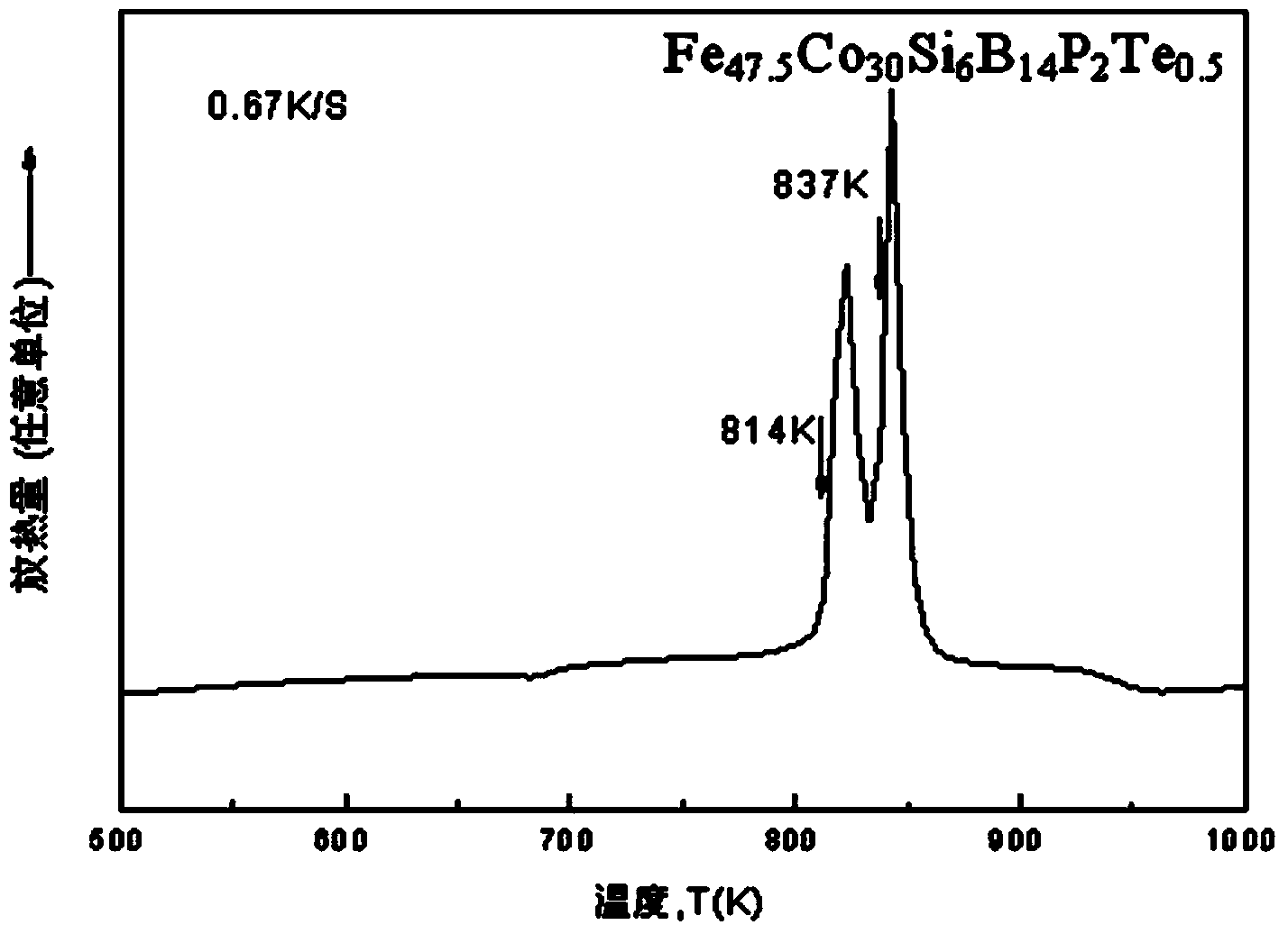

Embodiment 1

[0050] In the iron-based amorphous alloy Fe of the present invention a Si b B c P d m e A group of different alloy samples were prepared in the range of composition, and the composition of the samples was as shown in table 1, wherein the alloys with serial numbers of 1-9 and 22-25 were embodiments of the present invention (preparing the amorphous strip step by the single-roll quenching method) The conditions of filling argon after vacuumizing are used for preparation), and the alloy with serial number 10-21 is a comparative example of the present invention (it does not contain M element in its alloy composition, and the specific operation of the step of preparing amorphous strip by single-roller quenching method See Table 1 for the conditions, the alloy with serial number 26 adopts the alloy composition of the present invention but adopts atmospheric atmosphere to prepare in the step of preparing the amorphous strip by the single-roll quenching method, and the performance t...

Embodiment 2

[0063] In the iron-based amorphous alloy Fe of the present invention a Si b B c P d m e A group of different alloy samples were prepared, and the composition of the samples is shown in Table 2. The alloys with the sample numbers 27-45 and 49-58 were vacuum-filled and then filled in the single-roll quenching method to prepare amorphous strips. Argon gas conditions were used for preparation, while the alloys numbered 46-48 and 59-64 were prepared in atmospheric environment in the step of preparing amorphous strips by single-roll quenching method. The preparation method is the same as in Example 1, and the properties of samples 27-64 are tested by the same test method as in Example 1, and the measured results are shown in Table 2.

[0064] As can be seen from the sample analysis results of this embodiment: 1) the alloy strip structure of all samples of this embodiment is a completely amorphous structure; 2) all samples of this embodiment have excellent soft magnetic propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com