Coating paint for plywood and preparation method of coating paint

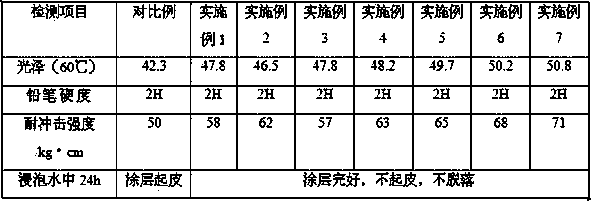

A coating and topcoat technology, which is applied in the field of coating topcoat for plywood and its preparation, can solve the problems of few types, gloss, hardness, and low impact strength, and achieve high impact strength, good appearance, and excellent The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment provides a coating finish paint for splints, which is prepared in parts by mass from the following raw materials: 50 parts of epoxy-modified acrylic resin, 18 parts of hexamethoxymethylmelamine resin, 7 parts of butyl acrylate, phthalate 3 parts of dibutyl formate, 0.015 parts of 2-amino-2-methyl-1-propanol, 3 parts of polyacrylate resin, 0.15 parts of cellulose acetate butyrate, 0.15 parts of polyorganosiloxane, alcohol-soluble and light-resistant 8 parts of yellow GR, 4 parts of dimethyl ether, 0.5 parts of water resistance agent, 7 parts of isopropanol, 3 parts of isopropyl acetate, and 7 parts of distilled water.

[0016] A kind of preparation step of splint coating finish paint is as follows:

[0017] (1) First mix the epoxy-modified acrylic resin, polyacrylate resin and butyl acrylate evenly, and stir for 20 minutes at a stirring speed of 1500r / min;

[0018] (2) Then add hexamethoxymethylmelamine resin, dibutyl phthalate, 2-amino-2-methyl-1-propan...

Embodiment 2

[0020] This embodiment provides a coating finish paint for splints, which is prepared in parts by mass from the following raw materials: 52 parts of epoxy-modified acrylic resin, 20 parts of hexamethoxymethylmelamine resin, 8 parts of butyl acrylate, phthalate 4 parts of dibutyl formate, 0.017 parts of 2-amino-2-methyl-1-propanol, 4 parts of polyacrylate resin, 0.17 parts of cellulose acetate butyrate, 0.16 parts of polyorganosiloxane, alcohol-soluble and light-resistant Yellow GR 9 parts, dimethyl ether 5 parts, water resistant agent 0.6 parts, isopropanol 9 parts, isopropyl acetate 4 parts, distilled water 8 parts.

[0021] A kind of preparation step of splint coating finish paint is as follows:

[0022] (1) First mix the epoxy-modified acrylic resin, polyacrylate resin and butyl acrylate evenly, and stir for 22 minutes at a stirring speed of 1550r / min;

[0023] (2) Then add hexamethoxymethylmelamine resin, dibutyl phthalate, 2-amino-2-methyl-1-propanol, cellulose acetate b...

Embodiment 3

[0025] This embodiment provides a coating finish paint for splints, which is prepared in parts by mass from the following raw materials: 59 parts of epoxy-modified acrylic resin, 22 parts of hexamethoxymethylmelamine resin, 11 parts of butyl acrylate, phthalate 5 parts of dibutyl formate, 0.026 parts of 2-amino-2-methyl-1-propanol, 5 parts of polyacrylate resin, 0.23 parts of cellulose acetate butyrate, 0.23 parts of polyorganosiloxane, alcohol-soluble and light-resistant Yellow GR 14 parts, dimethyl ether 9 parts, water resistant agent 1.8 parts, isopropanol 13 parts, isopropyl acetate 5 parts, distilled water 11 parts.

[0026] A kind of preparation step of splint coating finish paint is as follows:

[0027] (1) Mix epoxy-modified acrylic resin, polyacrylate resin and butyl acrylate evenly, and stir for 28 minutes at a stirring speed of 1750r / min;

[0028] (2) Then add hexamethoxymethylmelamine resin, dibutyl phthalate, 2-amino-2-methyl-1-propanol, cellulose acetate butyrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com