Heat-resistant and ageing-resistant acrylonitrile-butadiene-styrene (ABS) resin with high tensile strength and preparation technology of resin

A technology of ABS resin and high tensile strength, applied in the field of resin, can solve the problems of slightly insufficient application of ABS resin, difficulty in maintaining rigidity and hardness, and achieve the effects of no shrinkage and warping, improved heat resistance, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

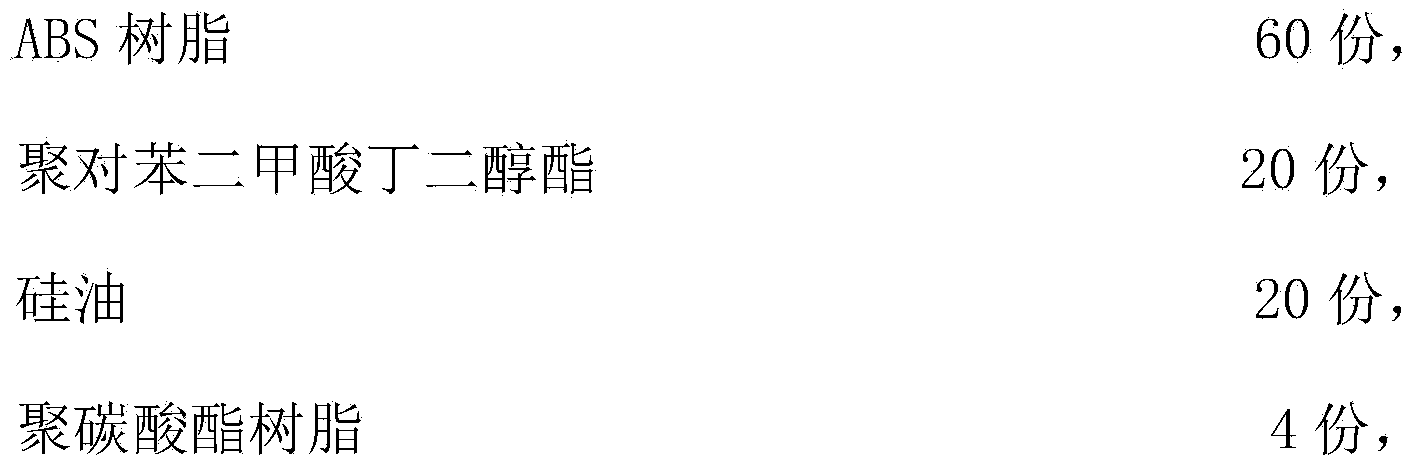

Embodiment 1

[0021] The present invention also proposes a method for preparing heat-resistant and aging-resistant high-tensile-strength ABS resin according to the above ratio of materials, comprising the following steps: feeding ABS resin, polybutylene terephthalate, and silicone oil into a high-speed mixer Mix evenly, then add tetrabromobisphenol A, antioxidant 1010, light stabilizer 944, light shielding agent, zinc stearate, nano silicon dioxide, toughening modifier, polycarbonate resin and polyurethane resin After mixing for 20 minutes, send it to a twin-screw extruder for extrusion, wherein the speed of the twin-screw extruder is 270r / min, and the temperatures of the front, middle, rear and head of the barrel of the twin-screw extruder are respectively: 180°C , 210°C, 205°C, 210°C.

Embodiment 2

[0023] The present invention also proposes a method for preparing heat-resistant and aging-resistant high-tensile-strength ABS resin according to the above ratio of materials, comprising the following steps: feeding ABS resin, polybutylene terephthalate, and silicone oil into a high-speed mixer Mix evenly, then add tetrabromobisphenol A, antioxidant 1010, light stabilizer 791, light shielding agent, zinc stearate, nano silicon dioxide, toughening modifier, polycarbonate resin and polyurethane resin After mixing for 30 minutes, send it to a twin-screw extruder for extrusion, wherein the speed of the twin-screw extruder is 250r / min, and the temperatures of the front, middle, rear and head of the barrel of the twin-screw extruder are respectively: 200°C , 205°C, 215°C, 200°C.

Embodiment 3

[0025] The present invention also proposes a method for preparing heat-resistant and aging-resistant high-tensile-strength ABS resin according to the above ratio of materials, comprising the following steps: feeding ABS resin, polybutylene terephthalate, and silicone oil into a high-speed mixer Mix evenly, then add tetrabromobisphenol A, antioxidant 1010, light stabilizer 770, light stabilizer 3853, light shielding agent, zinc stearate, nano silicon dioxide, toughening modifier, polycarbonate Resin and polyurethane resin are mixed at high speed for 25 minutes and sent to the twin-screw extruder for extrusion. The twin-screw extruder speed is 265r / min, and the temperature They are: 190°C, 208°C, 213°C, 205°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com